6 .8 drying the hydrolyzed samples, 6 .9 preparing the extraction, 6 .10 extraction – BUCHI Hydrolysis Unit B-411 User Manual

Page 20

6 Operation

20

B-411/E-416 Operation Manual, Version E

6 .8

Drying the hydrolyzed samples

Before drying the hydrolyzed samples stir the sample layer and the celite layer (without touching the

sand layer) with a spatula to loosen the pulp. Afterwards wipe the spatula with fat free cotton wool or a

tissue and put the tissue into the sample.

Dry the glass sample tubes in a vacuum oven (

≤ 4 h at 100°C/200mbar), in an oven (≤ 8 h at 100°C)

or in a microwave oven. Using a microwave oven makes the drying much faster. However, it is more

awkward due to the fact that the temperature in the sample can easily become too high (> 105 °C) if

an inappropriate heating power has been chosen.

Therefore, we suggest the following:

Step: 18 minutes with an output of 640 W

1.

Step: 10 minutes with an output of 480 W for 4 samples

2.

13 minutes with an output of 480 W for 6 samples

The optimal parameters for the microwave may depend on the model.

The sample is dry when there is no moisture to be seen on the glass wall.

ATTENTION

The plastic holders for the glass sample tubes and paper thimbles for the E-812/E-816 are not

microwavable.

6 .9

Preparing the extraction

Fill the dried, cooled, glass sample tubes with 20 g of quartz sand (grain size 0.3-0.9 mm). They are

now ready for extraction. The glass sample tubes are optimized for use either with the Extraction

System B-811 or with the Extraction Unit E-812/816.

6 .10

Extraction

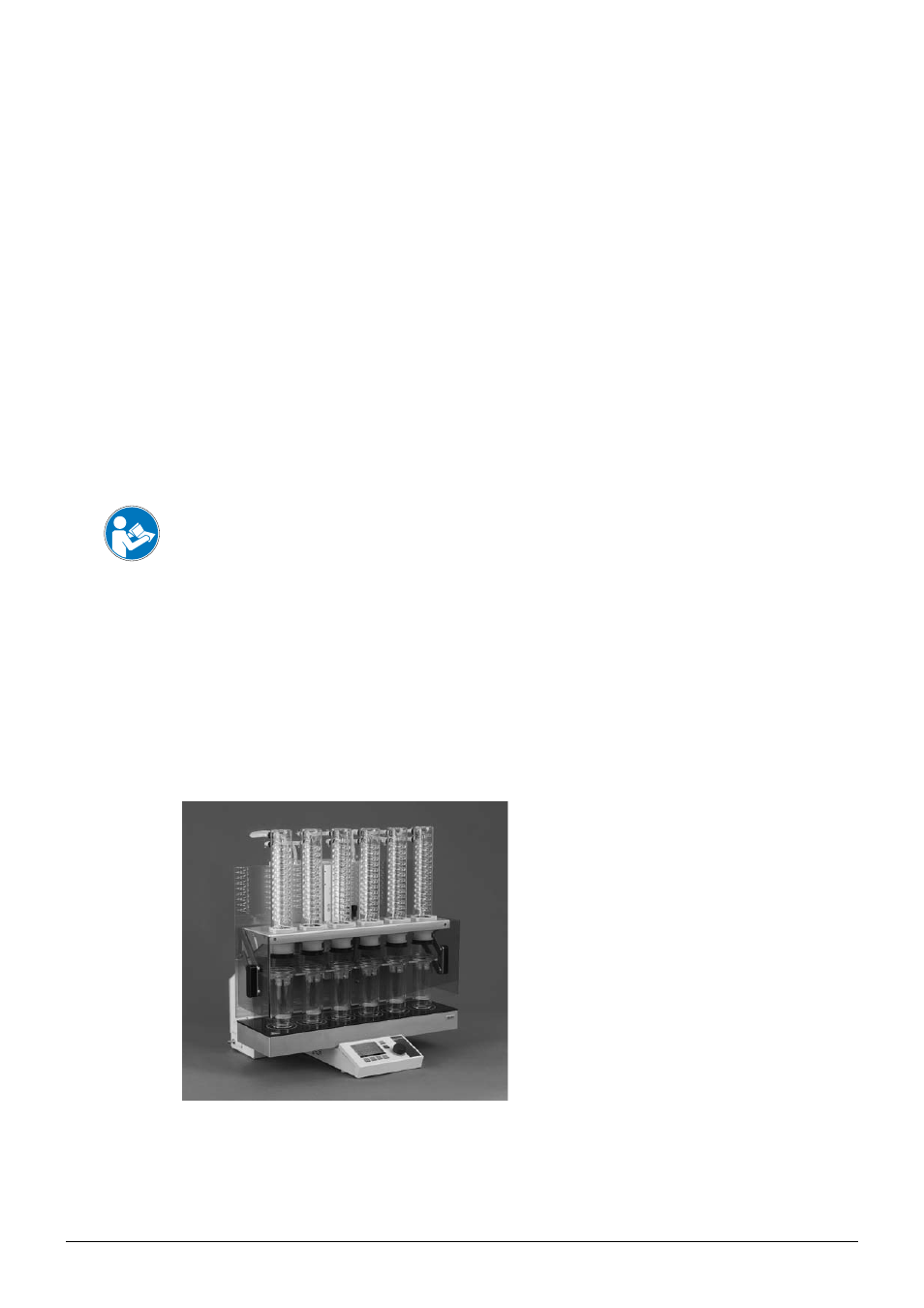

Buchi offers a wide range of fully automated ex-

traction units. Please consult the corresponding

brochures for detailed information.

Extraction Unit E-812 Soxhlet (2 positions)

•

Extraction Unit E-812 Hot Extraction (2 posi-

•

tions)

Extraction Unit E-816 Soxhlet (6 positions)

•

Extraction Unit E-816 Hot Extraction (6 posi-

•

tions)

Extraction System B-811 Standard (4 posi-

•

tions)

Extraction System B-811 LSV (4 positions)

•

Fig. 6.9: E-816 Hot Extraction