Appendix a - ku-2 calibration information – Brookfield KU-2 Viscometer User Manual

Page 11

Brookfield Engineering Labs., Inc.

Page 11

Manual No. M04-242-D0612

Appendix A - KU-2 Calibration Information

The accuracy of the KU-2 is verified using viscosity standard fluids calibrated in Krebs Units, which

are available from Brookfield Engineering Laboratories or your local Brookfield dealer/distributor/

representative. Note: Calibration should not be verified using the centipoise scale. The centipoise

scale is for reference use only and is based on a correlation from the Krebs Unit details in the ASTM

test method D562. Viscosity Standards are calibrated at 25°C. Available standards are listed in

Table A-1 below:

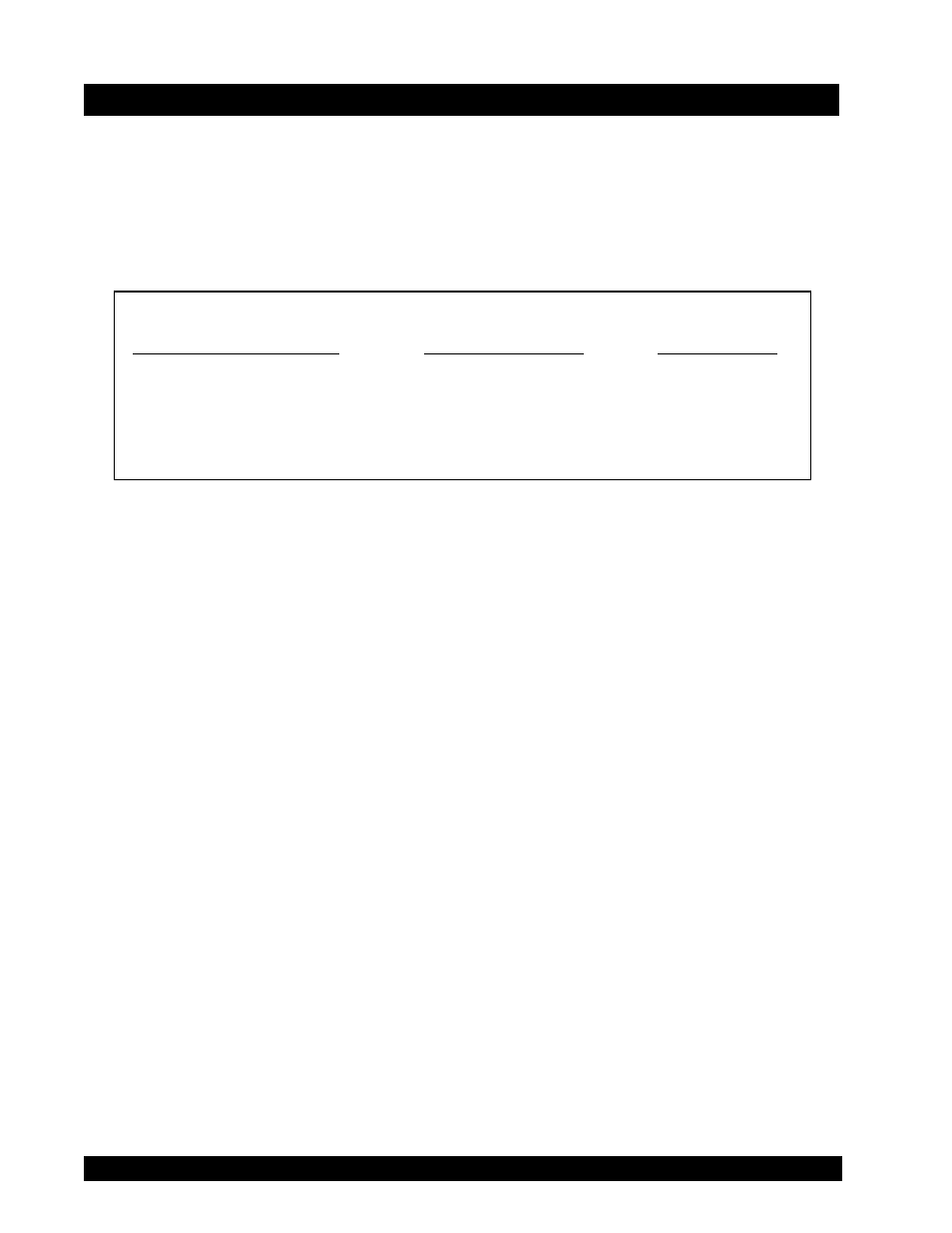

Table A-1

Brookfield Viscosity Standard

Nominal Viscosity (KU)

Temperature (°C)

KU61

61

25

KU73

73

25

KU87

87

25

KU99

99

25

KU106

106

25

Brookfield Viscosity Standards

We recommend that Brookfield Viscosity Standard Fluids be replaced on an annual basis, one year

from the date of initial use. These fluids can be stored under normal laboratory conditions. Disposal

should be in accordance with local, state and federal regulations. Material Safety Data Sheets are

available on our website: www.brookfieldengineering.com/support/documentation.

Calibration Check Procedure

The frequency of the calibration check should be based on your company's standard practice for test

and calibration of instruments.

1) Select any two viscosity standards listed in Table A-1 to perform your calibration check.

The viscosity standards are very temperature sensitive. The viscosity value of the fluid will

change with temperature so it is important to control the temperature to 25.0°C.

Note: Do not use viscosity standards calibrated in centipoise.

2) Pour the selected fluid into a standard US 1-pint can. The spindle and the fluid in the can

should come to temperature equilibrium before proceeding with the calibration check.

It is important that the fluid and the spindle come to 25.0°C, ± 0.1°C, before proceeding

with the calibration check.

3) Once the fluid and spindle have come to thermal equilibrium, place the sample container

on the viscometer base, using the KU1-74 adapter. Switch the power switch and printer (if

used) to "ON". Switch the Hold Reading Switch to the "UP" position. Turn the Select knob

to "KU".

4) Move the viscometer handle down to the lowest position. The spindle will begin rotating

once the handle is within 1/2 inch of the lowest position.