Brookfield Dial Viscometer User Manual

Page 26

Brookfield Engineering Laboratories, Inc.

Page 26

Manual No. M/85-150-P700

D2. Consult with Brookfield or an authorized dealer to determine which fluid is

appropriate.

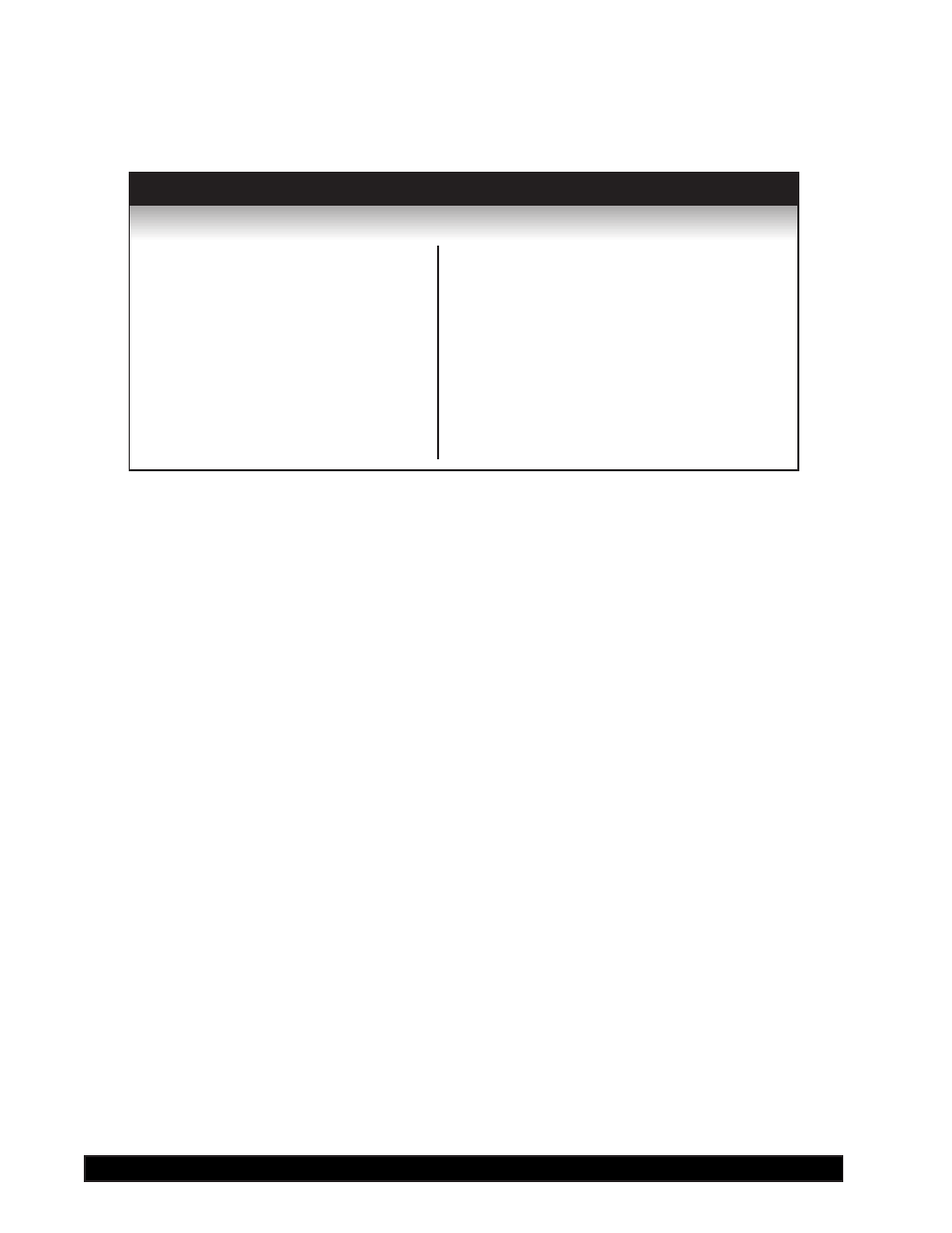

TABLE D2

OIL VISCOSITY STANDARD FLUIDS

BEL Part No.

Viscosity (cP) 25

°

C

B31

31

B210

210

B750

750

B1400

1,400

B2000

2,000

B11000

11,000

B20000

20,000

B80000

80,000

B200000

200,000

B420000

420,000

Interpretation of Calibration Test Results:

When verifying the calibration of the Viscometer, the instrument and viscosity standard fluid error must

be combined to calculate the total allowable error.

The Dial Viscometer is accurate to

±

1% of any full scale spindle/speed viscosity range.

Brookfield Viscosity Standards Fluids are accurate to

±

1% of their stated value.

Example: Calculate the acceptable range of viscosity using RVF with RV-3 Spindle at 2 RPM;

Brookfield Standard Fluid 12,500 with a viscosity of 12,257 cP at 25

°

C:

1) Refer to the instructions on the FACTOR FINDER. Calculate the full scale viscosity range by

multiplying the spindle/speed FACTOR by 100.

Spindle RV-3, 2 RPM FACTOR = 500

Full scale viscosity range is 500 x 100 = 50,000 cP

The viscosity is accurate to

±

500 cP (which is 1% of 50,000)

Note: All spindle/speed factors found on the FACTOR FINDER are equivalent to 1% of

the spindle/speed full scale viscosity range.

2) The viscosity standard fluid is 12,257 cP. Its accuracy is

±

1% of 12,257 or

±

122.57 cP.

3) Total allowable error is 122.57 + 500 cP =

±

622.57 cP.

4) Therefore, any viscosity reading between 11,634.4 and 12,879.6 cP indicates that the viscom-

eter is operating correctly. Any reading outside these limits may indicate a viscometer problem.