Connecting air service – Cissell LDBB User Manual

Page 20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

AJ1031

18

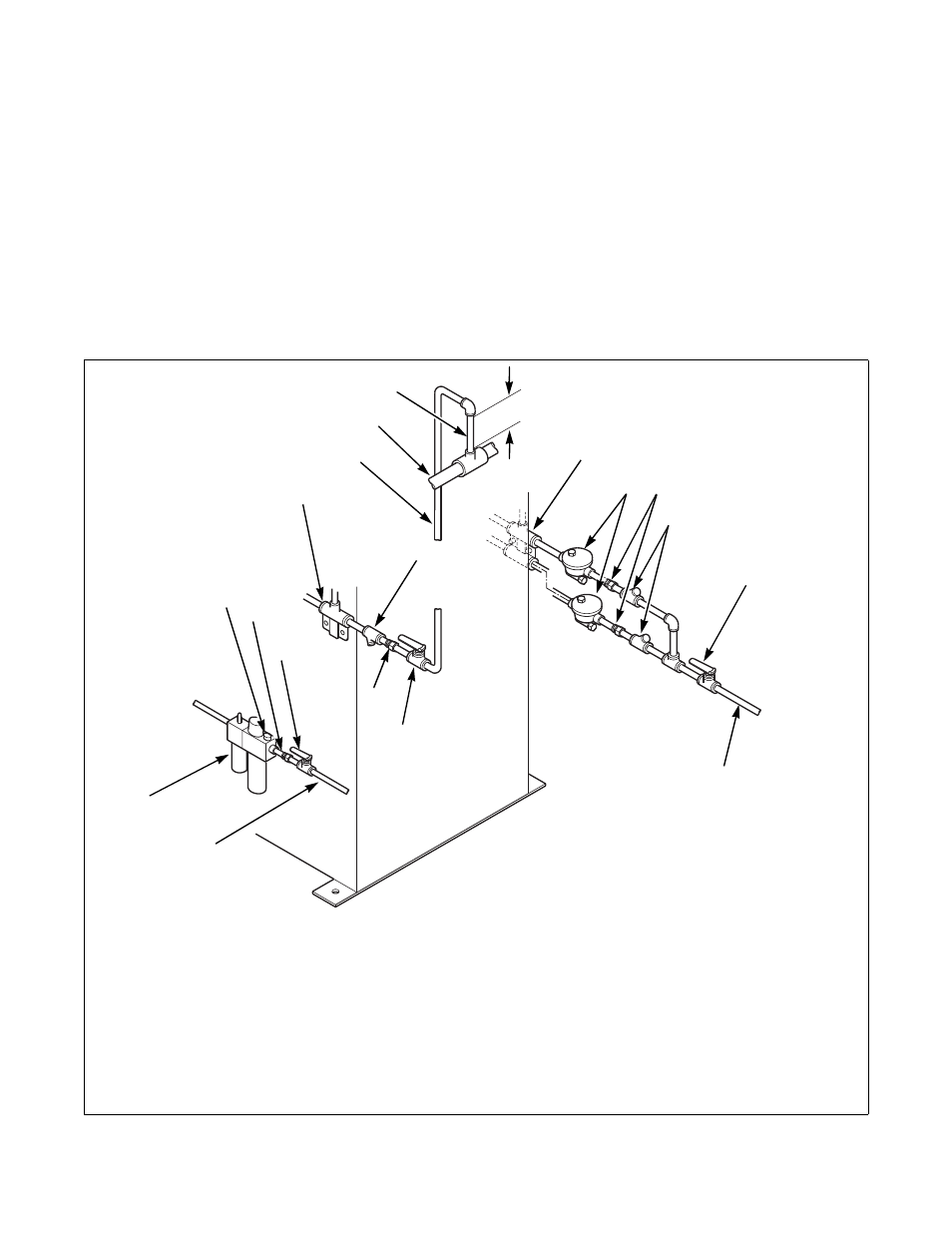

Connecting Air Service

(Refer to Figure 8)

Air service connected to press must have a

MINIMUM constant pressure of 80 psig (5.52 bar)

and be of ample volume to meet requirements listed in

data table (refer to Table 1). Air pressure should be

reduced to 75 to 80 psig (5.17 to 5.52 bar) at air inlet

regulator. It is customer’s responsibility to connect air

line with galvanized pipe, brass, aluminum or stainless

steel pipe, copper tubing, fittings, shut-off valve,

union, air filter and air dryer suitable for delivery of

clean, dry air to inlet.

NOTE: Failure to provide clean, dry air to press

WILL cause premature valve FAILURE and

UNNECESSARY DOWNTIME.

A shut-off valve and union placed at each unit is

recommended.

Figure 8

SCR100N

1

Steam Return*

9

Filter Regulator Lubricator*

2

Steam Trap

10

Steam Inlet*

3

Check Valve

11

Steam Supply Line

4

Union

12

Header

5

Steam Return Shut-Off Valve

13

Riser

6

To Steam Return

14

Downstream Relieving Shut-Off Valve

7

Steam Strainer

15

Steam Supply Shut-Off Valve

8

Air Supply

16

Air Supply Line Shut-Off Valve

*Parts installed on press by manufacturer

SCR100N

3" MIN.

1

2

3

4

6

15

4

7

10

4

16

9

8

11

12

13

5

14