Fuel flow sensor, General placement recommendations, Floscan transducer installation – Dynon Avionics EMS-D120 Installation Guide User Manual

Page 23: Ei “red cube” installation, Rotax placement recommendations, Fuel flow sensor -9

Transducer

Installation

Fuel Flow Sensor

Pin

Color

Function

Dynon Avionics supplies two different fuel flow

transducers:

13 Black Ground

Yellow (or

white)

Fuel flow

input

EMS-D120 Installation Guide

3-9

¼” NPT Female

Floscan 201B (Dynon P/N 100403-001)

Electronics International FT-60 (Dynon P/N 100403-003)

GENERAL PLACEMENT RECOMMENDATIONS

14

15 Red

When placing either sensor, ensure that the three wire leads

are pointed straight up. A filter should be placed upstream

from the sensor to screen out debris. Placement of the fuel

flow sender relative to other items in the fuel system like fuel pumps is left to the builder. The

manufacturer of the fuel flow sender does not make strong recommendations on this point. It is

not uncommon, though, to place the sender downstream of any auxiliary electric boost pumps

but upstream of the engine driven fuel pump. For best measuring performance, the fuel should

travel uphill by one to two inches after leaving the fuel flow sender.

Fuel flow

power

(14V)

Due to vibration issues, never connect the sensor directly to engine.

Do NOT use Teflon tape when screwing in any of the fittings.

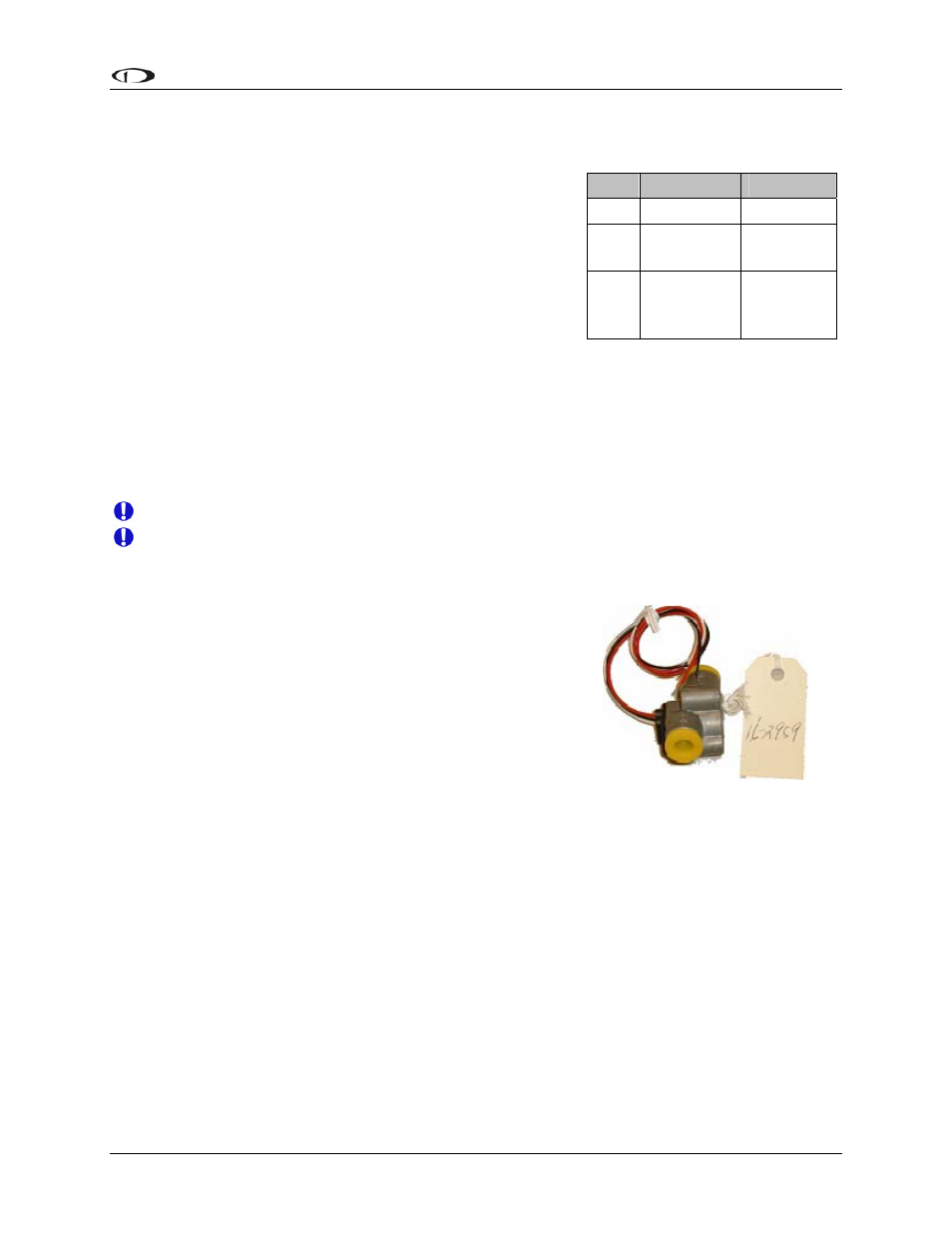

FLOSCAN TRANSDUCER INSTALLATION

The FloScan fuel flow transducer has ¼” female NPT threads

at both the inlet and outlet. Only use ¼” NPT fittings to match.

When installing, do not screw fittings more than two full turns

past hand tightened. The torque should not exceed 180 inch-

lbs.

Make note of the numbers on the tag attached to the fuel

flow sensor. You will need it in the Fuel Flow Configuration

section on page 5-14.

EI “RED CUBE” INSTALLATION

The Electronics International “Red Cube” FT-60 flow transducer has ¼” female NPT ports. Do

not exceed a torque of 300 inch-lbs when installing fittings into the transducer. The fuel line on

the outlet port should not drop down after exiting the transducer. This configuration can trap

bubbles in the transducer, causing jumpy readings.

The inlet port, outlet port, and flow direction are marked on the top of the FT-60.

ROTAX PLACEMENT RECOMMENDATIONS

If installing on a Rotax 912, review the following page for recommendations specific to these

engines.