Priming the pump – Beckett 7505 User Manual

Page 10

10

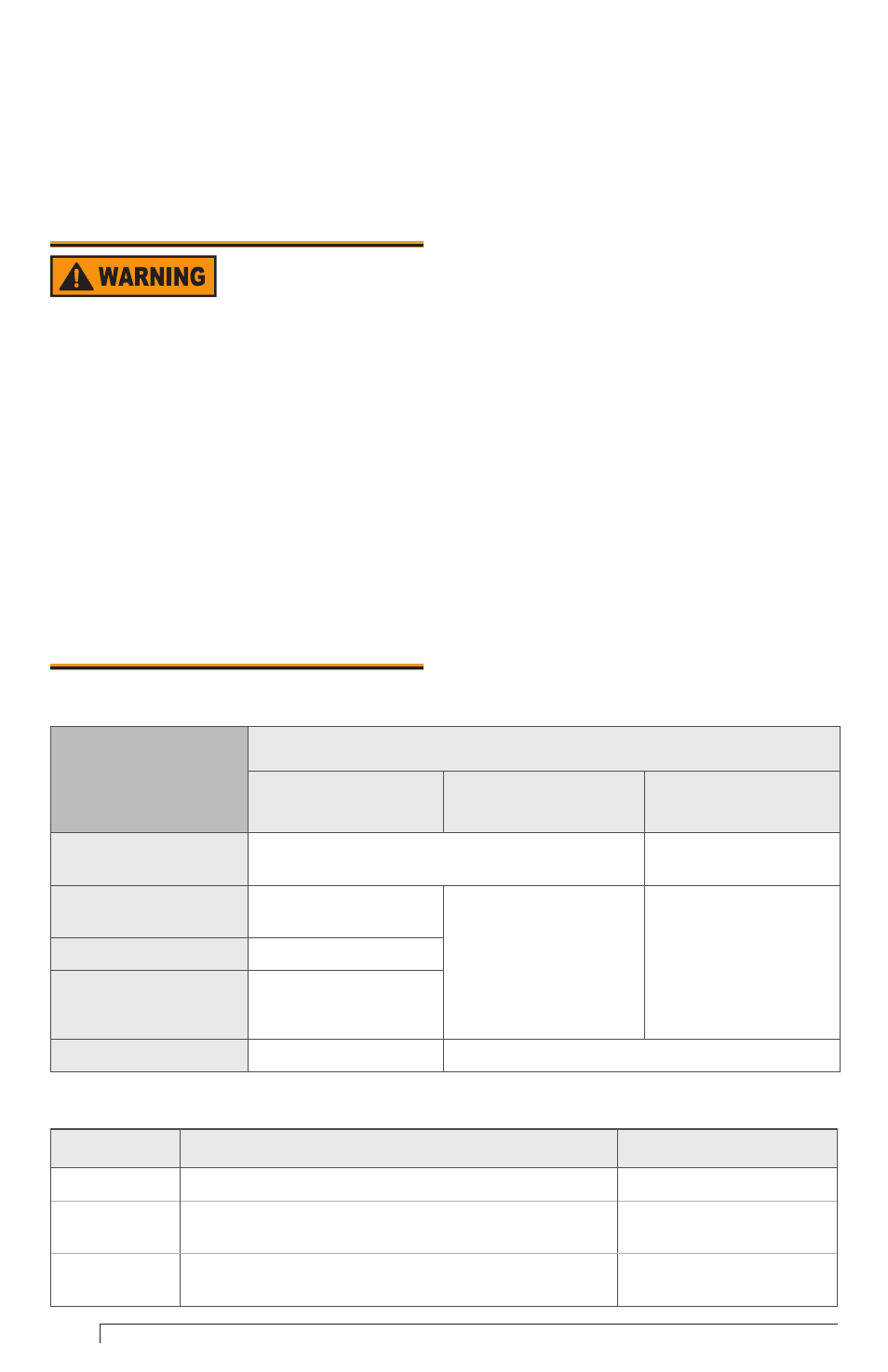

If the burner is in the

below state:

Pushing the reset button will:

Button Click

(press < 1 second)

Button Hold

(press > 1 second)

Button Hold

(press 15+ seconds)

Lockout

Reset from Soft Lockout

Reset from Restricted

(Hard) Lockout

Valve-on Delay, Trial for

Ignition, Ignition Carryover

Go to Pump Prime (see

“Priming the Pump” above)

Disable the Burner:

Any time the burner is

running, press and hold

the reset button to disable

the burner. The burner will

remain off as long as the

button is held.

Enables Pump Priming:

After the reset button has

been held for 15 seconds,

the button can then be

clicked during the next

ignition sequence to enter

Pump Prime mode.

Run (igniter is shut off)

No action

Motor-Off Delay,

Standby

No action

Pump Prime

No action

Exit Pump Prime mode and return to Standby

Table 2 - Reset Button Operation

Light Color

On Continuously

Flashing

Red

Restricted (Hard) Lockout

Soft Lockout

Green

Flame Sensed during normal operation (Could be stray

light during standby)

Recycle

Yellow

Control is in Pump Prime mode or

Reset button currently held for 15+ seconds.

N/A

Table 3 - Status Lights

Initiate a call for heat.

After the burner starts, press and

hold the reset button for 15 seconds

until the yellow light turns on. This

indicates that the button has been

held long enough.

Release the reset button. The yellow

light will turn off and the burner will

start up again.

At burner start up, click the reset

button while the igniter is still on.

This will transition the control to a

dedicated Pump Prime mode, during

which the motor, igniter, and valve

are powered for four minutes. The

yellow light will be on.

Bleed the pump until all froth and

bubbles are purged. If desired,

terminate the call for heat or hold the

reset button for at least one second

to exit Pump Prime mode and return

to Standby.

At the end of 4 minutes, the yellow

light will turn off and the control will

2.

3.

4.

5.

6.

7.

Do not allow oil to spray into a hot

combustion chamber while bleeding air from

the pump.

Install a gauge in the nozzle discharge port

tubing or fully open the pump bleed valve to

prevent oil spray from accumulating in the

combustion chamber during the air bleed

procedure.

Ensure that all bubbles and froth are purged

from the oil supply system before tightening

the pump bleed valve.

Ensure that the appliance is free of oil and oil

•

•

•

•

Failure to bleed the pump properly could

result in unstable combustion, hot gas puff-

back and heavy smoke.

Hot Gas Puff-Back

and Heavy Smoke

Hazard

Priming the Pump

Prepare the burner for priming

by attaching a clear plastic hose

over the bleed port fi tting and fully

opening the pump bleed port. Use a

suitable container to collect purged oil.

1.