Beckett CF1000 User Manual

Page 7

7

CF1000 Burner Manual

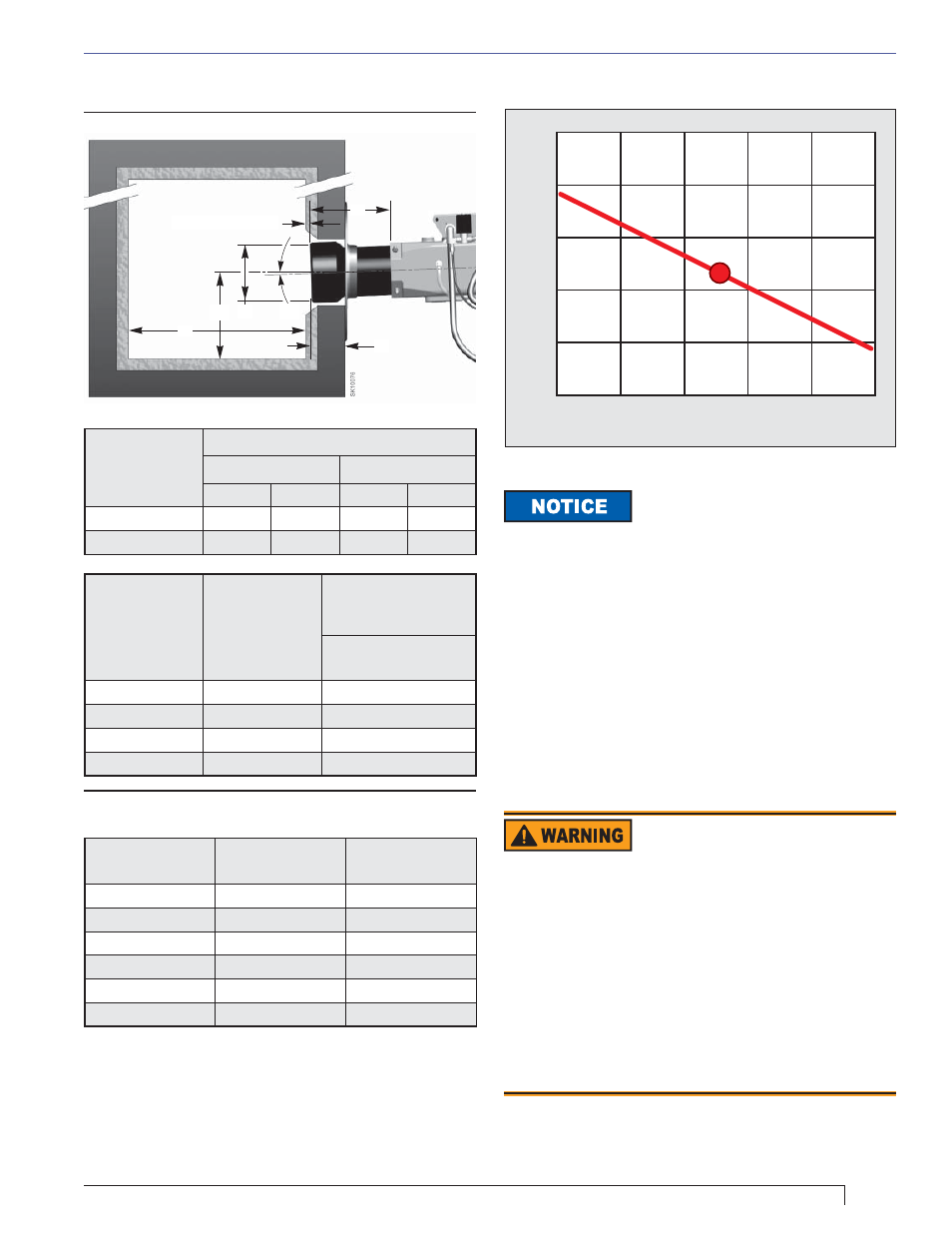

Firing Rate

Minimum Dimensions

(refractory-lined)

(wet-base boilers)

H

L

H

L

0 to 5 gph

7.0”

25.0”

7.0”

25.0”

5 to 10 gph

8.0”

35.0”

8.0”

40.0”

Table 2 - Air Tube Capacity (GPH) vs. Firebox Pressure

Firebox Pressure

(In W.C.)

No Reserve Air

10%Turndown

(GPH)

0.0

11.0

10.00

0.2

10.5

9.45

0.4

10.1

9.10

0.6

9.6

8.64

0.8

9.2

8.30

1.0

8.7

7.83

Note: 10% turndown indicates suffi cient reserve air to reduce

the CO

2

in the fl ue to 90% of its value.

Note: The above ratings may vary 5% due to variations in

actual job conditions.

Stray Light

Protect Against Stray Light Lockout. Failure to follow

these instructions could cause loss of burner operation

resulting in no heat, an unplanned process interruption,

work stoppage and the potential for frozen plumbing or

other cold weather property damage.

The control must detect a dark, no-fl ame condition

in order to start the burner or it will hold in the stray

light lockout mode.

Shield the burner view window from direct exposure

to intense light.

○

○

Air Tube

Length

(Dimension T)

Minimum

Insertion Depth

(Dimension E)

A.T.C. Codes

(A.T.C. = Air Tube

Combination)

Tube A

(Dim. D = 5.5”)

0

6.75”

2.94”

CF66KD

10.25”

2.94”

CF102KD

13.75”

2.94”

CF136KD

17.75”

2.94”

CF176KD

Dust and Moisture

Protect Against Dust and

Moisture

Wet, dusty environments could lead to blocked

air passages, corrosion damage to components,

impaired combustion performance and

result in asphyxiation, explosion or fi re.

This burner is designed for clean, dry installations.

Electrical controls are not protected against rain or

sprayed water.

Keep the installation clear of dust, dirt, corrosive

vapors, and moisture.

Protective covers and more frequent maintenance

may be required.

○

○

○

○

Section: Pre-installation Checklist

Figure 2 - Dimensions: Minimum Combustion

Chamber and Air Tube Mounting.

Figure 3 - Firebox Pressure: CF1000 with no Reserve Air

0.2

0.4

0.6

0.8

1.0

0.0

12

11

10

9

Firebox Pressure in Inches Water Column (W.C.)

Maximum Firing Rate U.S. GPH

K D

13

14

15

* Install burner with

2° pitch as shown.

*2°

H

L

T

D

E

1/4” ± 1/8”