Warning – Cub Cadet 53AJ8CT6050 User Manual

Page 22

22

2.

Leaking Tires: When a flat tire occurs, repair or

replace immediately. The normal procedure is to

remove the wheel and replace it with a spare.

Take the leaking tire to a maintenance area and

repair. If a tire is getting soft, park the mower on

the nearest level, paved area. If the leaking tire

is on a traction wheel, put blocks on each side of

the opposite traction wheel and jack up the tire

that leaks about an inch off the ground. Loosen

and remove the lug nuts and remove the wheel.

Mount a spare wheel and tire, replace the lug

nuts, and using a torque wrench, tighten them to

60

±

10 lb-ft.

If the leaking tire is on a front caster wheel,

block both traction wheels and raise the caster

wheel so that the tire is an inch off the ground.

Loosen and remove the locknut from the axle

assembly and pull the axle assembly from the

caster yoke. The wheel and two spacer sleeves

will drop free. Slip the axle assembly through

one side of the caster yoke, through a spacer

sleeve, a spare wheel, the other spacer sleeve

and finally through the other side of the caster

yoke. Then tighten the locknut on the end of the

axle assembly.

Lower the mower off the jack and continue

mowing. The wheel with the leaking tire should

be taken to the maintenance area, the tire

inflated to 20 psi and the wheel placed in a

large bucket of water. Carefully inspect the tire,

rim and valve for escaping air bubbles which

indicate a leak. Mark each leak with a yellow

marking crayon and then deflate the tire to 8 psi

and repeat the inspection. If the leaks you find

are pin hole size to 1/16" diameter, the tire can

be repaired using an aerosol can of tire inflater

and latex sealer available from any auto supply

store. Follow the directions on the can. If the

leaks are larger than 1/16" diameter, the tire can

be repaired with rubber plugs also available in a

kit from any auto supply store. If the tire bead is

damaged, a tube will have to be installed in the

tire or the tire will have to be replaced.

3.

Creeping: Creeping is the slight forward or

backward movement of the mower when the

throttle is on and the lapbars are in the neutral

position. If your mower creeps refer to Steering

lever Adjustments Section G4, page 23.

F. Brakes

While the mower is in motion, all braking is performed

dynamically through the hydraulic pumps and traction

motors, controlled by the two steering levers. When the

mower is parked with the engine shut off, the hydraulic

system locks the traction wheels.

Note:

To move the mower forward or in reverse

by pushing, you must release the dynamic braking.

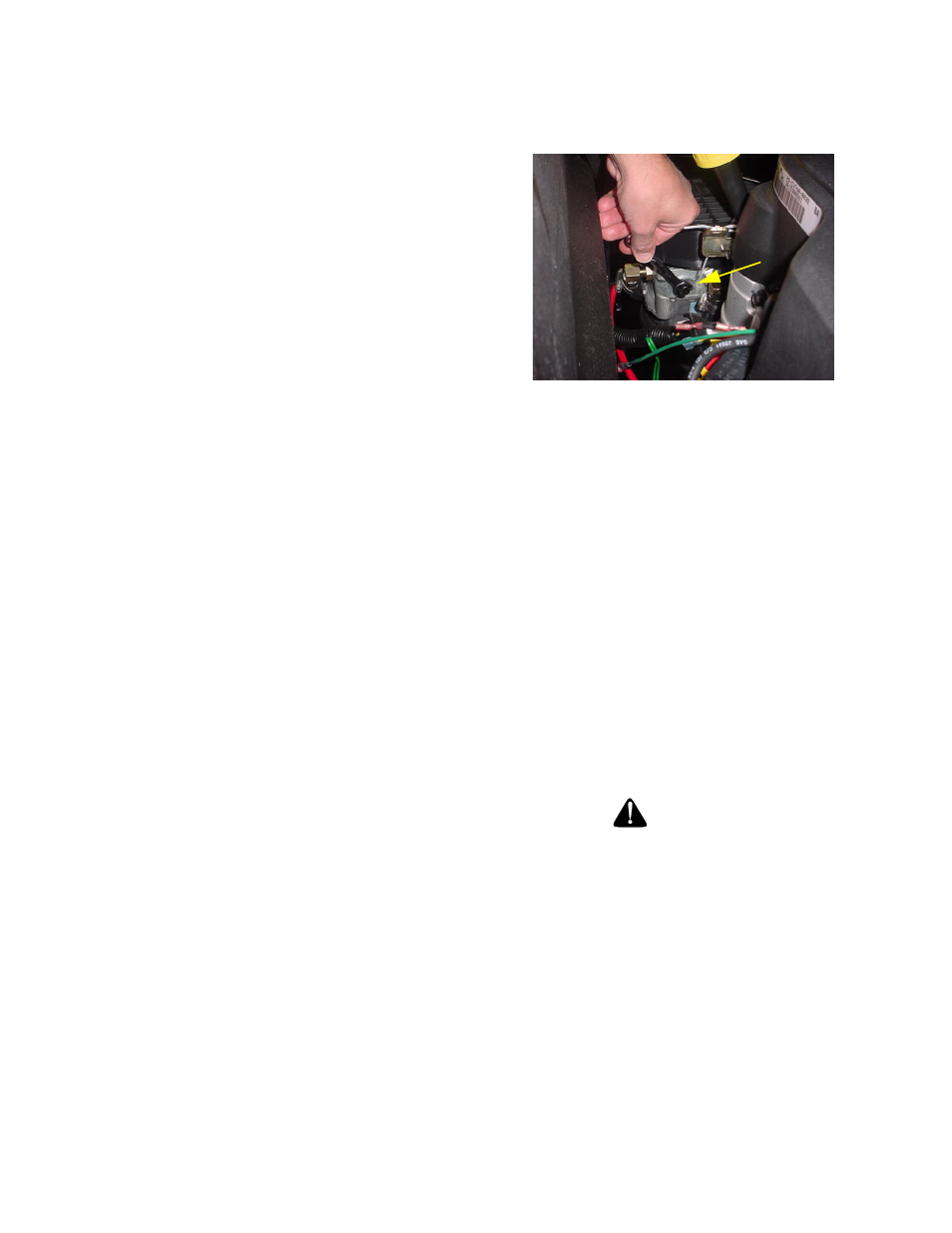

Locate the valves on the pump. Turn valves

counter-clockwise (using a standard 7/16” wrench)

one quarter turn to push the unit. After pushing the

mower to the desired location, return both valves

to the operating position by turning the valve

clockwise, but do not overtighten (See photo

below)

Left Side Pump

Bypass

Valve

.

When the mower is parked with the engine running and

the steering levers in the neutral position, the parking

brakes should be applied. The parking brakes are drum-

type brakes mounted on each traction wheel. They are

both engaged by the same operating lever.

1.

Adjustments: The parking brake handle is an

overcenter lever that should engage with moder-

ate force.

Note:

To increase parking brake capacity,

adjust brake cables at the brake arms equally.

Adjust the cable housing nuts one full turn and

check parking capacity. Repeat if parking brake

does not hold.

2.

Repair: The mower is equipped with drum

brakes and will not normally require mainte-

nance. If they are not working properly, please

contact your service center.

G. Hydraulic System

WARNING:

Never overfill the hydraulic units. Damage can

occur if the oil level is not within the proper oper-

ating range.

Note:

When adding hydraulic oil, do so in

small quantities and recheck the oil level before

adding more. It is important that you do not over-

fill the reservoir to allow for fluid expansion.

1.

Hoses: Check the hoses from the hydraulic oil

tank to the oil filter to the hydraulic lines daily for

leaks or abrasion and replace any damaged