Carrier 38HDF018-036 User Manual

Page 4

4

Only use factory specified liquid-line filter driers with rated

working pressures less than 600 psig.

NOTE: Do not install a suction-line filter drier in liquid line.

MAKE PIPING SWEAT CONNECTIONS — Remove plastic

caps from liquid and suction service valves. Use refrigerant

grade tubing. Service valves are closed from the factory and are

ready for brazing. After wrapping the service valve with a wet

cloth, the tubing set can be brazed to the service valve using ei-

ther silver bearing or non-silver bearing brazing material. Con-

sult local code requirements. Refrigerant tubing and the indoor

coil are now ready for leak testing.

NOTE: Unit is shipped with R-410A factory charge indicated

on nameplate.

Pass nitrogen or other inert gas through piping while braz-

ing to prevent formation of copper oxide.

PROVIDE SAFETY RELIEF — A fusible plug is located in

unit suction line; do not cap this plug. If local code requires

additional safety devices, install as directed.

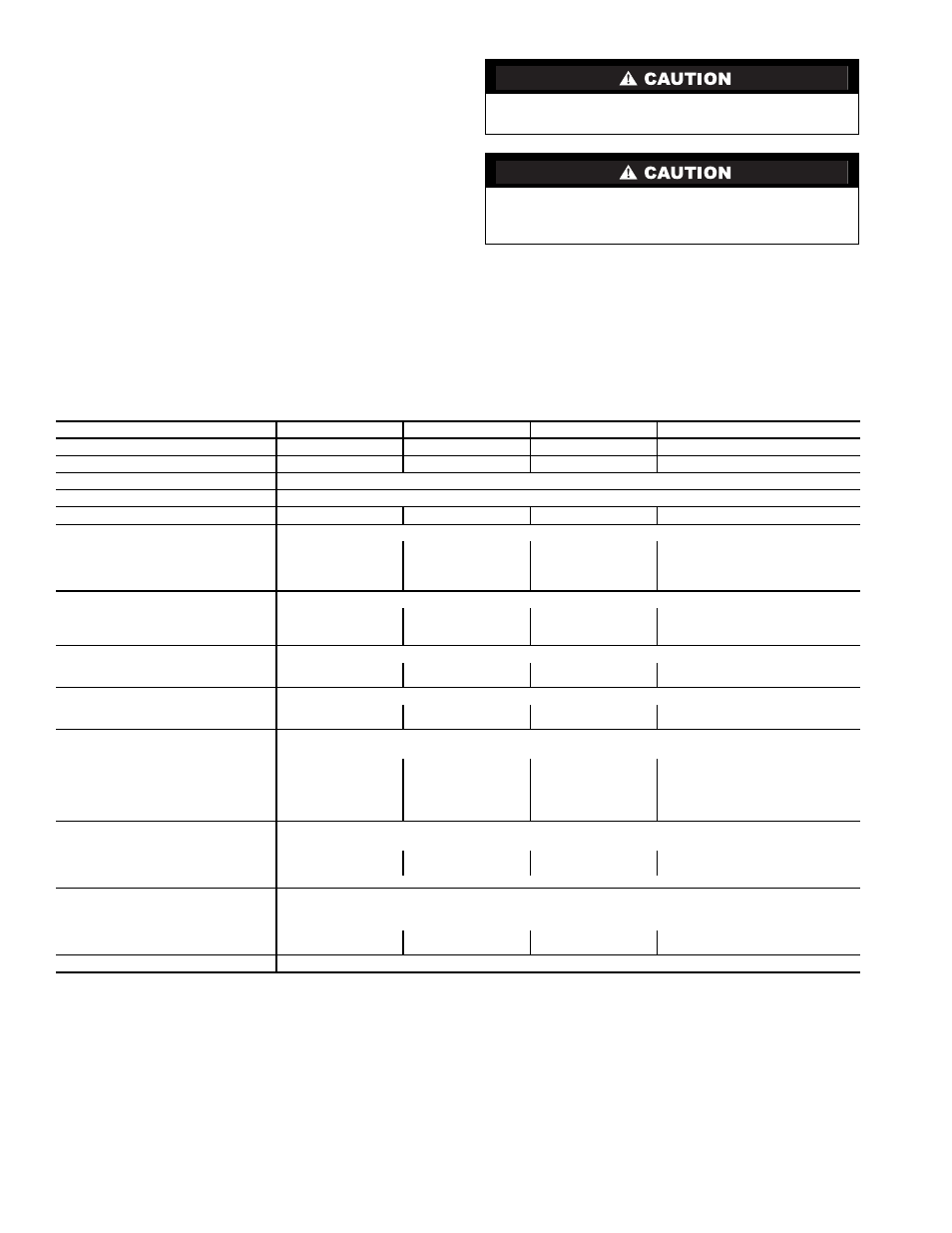

Table 1A — 38HDF018-036 Physical Data

LEGEND

*Unit shipped with full factory charge. See ARI (Air Conditioning and

Refrigeration Institute) capacity table for proper charge and piston

for each fan coil type.

†24 v and a minimum of 40 va is provided in the fan coil unit.

To avoid damage while brazing, service valves should be

wrapped with a heat-sinking material such as a wet cloth.

When brazing tubing sets to the service valves, a brazing

shield MUST be used to prevent damage to the painted unit

surface.

UNIT 38HDF

018

024

030

036

NOMINAL CAPACITY (Tons)

1.5

2.0

2.50

3.0

OPERATING WEIGHT (lb)

166

176

187

250

REFRIGERANT TYPE

R-410A

METERING DEVICE

AccuRater (Located at Fan Coil)

CHARGE (lb)*

4.8

5.3

5.0

7.1

OUTDOOR FAN

Rpm/Cfm

840/1720

840/1720

840/1720

850/1720

Diameter (in.)

18

18

18

24

No. Blades

3

3

3

3

Motor (hp)

1

/

8

1

/

8

1

/

8

1

/

4

OUTDOOR COIL

Face Area (sq ft)

5.82

7.27

7.27

12.1

No. Rows

2

3

3

2

FPI

20

20

20

20

HIGH PRESSURE SWITCH

Cut-In (psig)

420 ± 25

420 ± 25

420 ± 25

420 ± 25

Cutout (psig)

650 ± 10

650 ± 10

650 ± 10

650 ± 10

LOW PRESSURE SWITCH

Cut-In (psig)

45 ± 25

45 ± 25

45 ± 25

45 ± 25

Cutout (psig)

20 ± 5

20 ± 5

20 ± 5

20 ± 5

REFRIGERANT LINES

Connection Type

Sweat

Liquid Line (in.) OD

3

/

8

3

/

8

3

/

8

3

/

8

Vapor Line (in.) OD

5

/

8

5

/

8

3

/

4

3

/

4

Max Length (ft)

200

200

200

200

Max Lift (ft)

65

65

65

65

Max Drop (ft)

150

150

150

150

COMPRESSOR

Type

Scroll

Model

ZP16K5E-PFV

ZP21K5E-PFV

ZP25K5E-PFV

ZP34K5P-PFV

Oil Charge (POE - oz)

25.0

25.0

25.0

42.0

Accumulator

Yes

CONTROLS

Fusible Plug (F)

210

Control Voltage†

24 vac

System Voltage

208/230 v

208/230 v

208/230 v

208/230 v, Single and 3 Phase,

460 v, 3 Phase

FINISH

Gray

FPI

— Fins Per Inch

POE — Polyol Ester