Maintenance, Warning – Ryobi JM80 User Manual

Page 18

Page 18

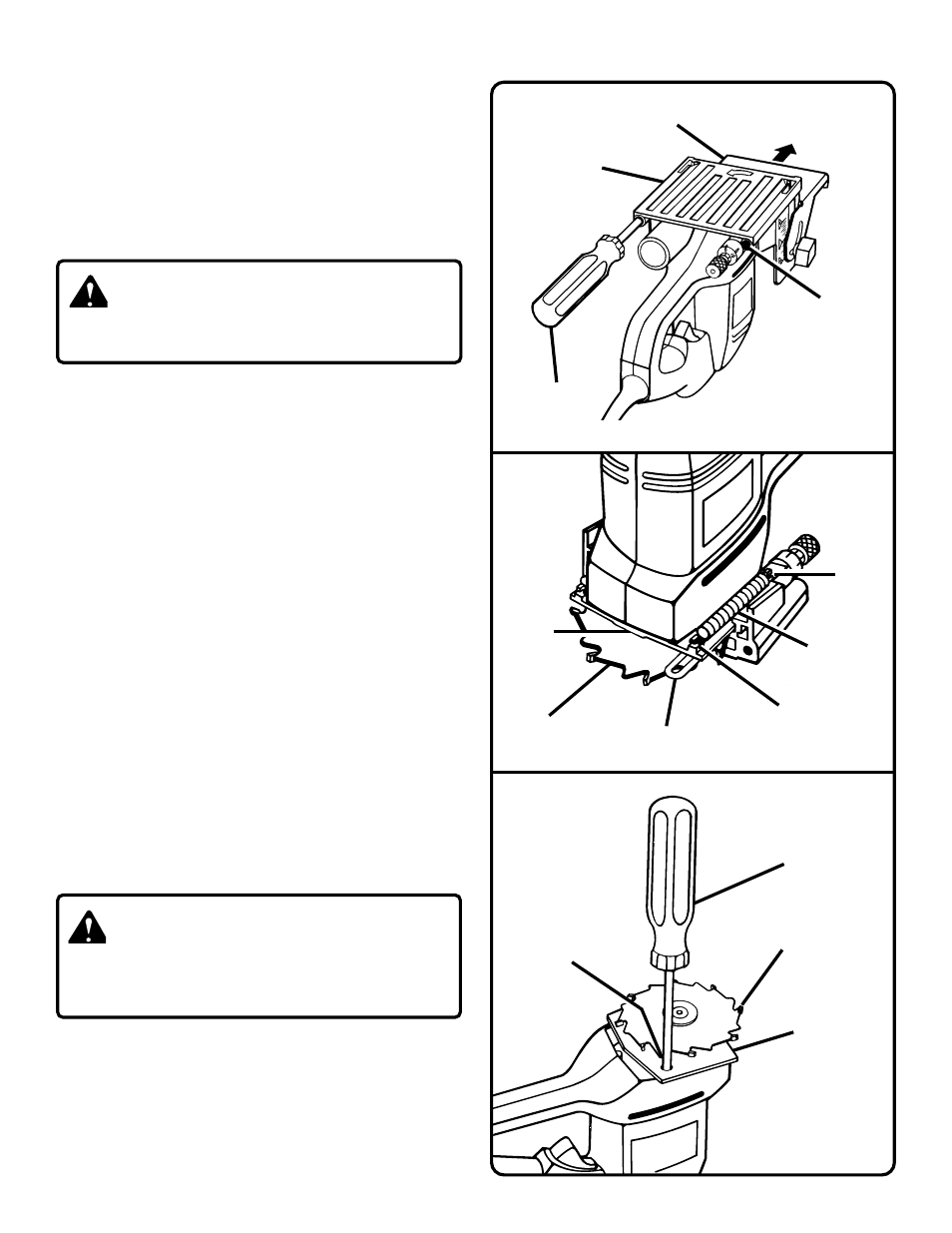

Fig. 26

MAINTENANCE

BLADE REPLACEMENT

See Figures 24-27.

After extended use, the blade on your plate joiner may

become dull and need replacing. If you accidentally hit a

nail or other blunt object, it will break the carbide tips on the

blade. These situations also require replacing the blade.

HOW TO REPLACE THE BLADE

1. Unplug your plate joiner.

2. Remove dust bag.

3. Place your plate joiner upside down on a workbench as

shown in figure 24.

4. Using a screwdriver remove the two screws securing

front base assembly.

5. Pull adjustable fence in the direction shown by the arrow

in figure 24 and remove front base assembly.

6. Using a pair of needle nose pliers, stretch and release

springs from tabs on bearing plate.

See Figure 25.

7. Push adjustment rod away from bearing plate and remove

rear base assembly.

8. With base assemblies removed, place plate joiner upside

down on a workbench as shown in figure 26.

9. Place a #2 Phillips screwdriver or 1/4 in. diameter pin in

one of the two holes provided in bearing plate.

10. Place one of the non-cutting teeth located behind each

carbide tipped cutting tooth against the screwdriver or

pin and lock blade preventing it from rotating. DO NOT

lock blade against one of the cutting teeth. Carbide

tips will break.

11. Using a 3/16 in. wrench, remove blade screw. NOTE:

Turn blade screw counterclockwise to remove.

See

Figure 27.

12. Remove outer blade washer and blade.

13. Clean wood particles and resin from blade washer, dust

bag area, base assembly slots, and all surrounding parts.

14. Place inner blade washer on gear spindle.

See Figure

27.

15. Place new blade onto shoulder of blade washer and

secure with outer blade washer and blade screw.

NOTE: Blade screw fits into cupped side of outer blade

washer.

WARNING:

Failure to unplug your plate joiner could result in accidental

starting causing possible serious personal injury.

WARNING:

If inner blade washer has been removed, replace it

before installing new blade. Failure to do so could cause

an accident since blade screw will not tighten properly.

#2 PHILLIPS SCREWDRIVER

OR 1/4 IN. DIAMETER PIN

CARBIDE TIPPED

CUTTING TOOTH

BEARING

PLATE

NON-CUTTING

TOOTH BEHIND

CARBIDE TIPPED

CUTTING TOOTH

Fig. 25

BEARING

PLATE

ADJUSTMENT ROD

BLADE

TAB(S)

SPRING(S)

NOTCH

Fig. 24

SCREWDRIVER

SHOWN WITHOUT DUST BAG

ADJUSTABLE

FENCE

SCREW

HOLE

TO

REMOVE

FRONT BASE

ASSEMBLY