Nexen H-1000 810080 User Manual

Page 8

8

FORM NO. L-20143-J-1209

AIr COnneCTIOnS

An Air Line (Item 20) is furnished and air controls with 1/8

NPT ports are recommended. Where long air lines are

required, a Quick Exhaust Valve (Product No. 945100) is

recommended to ensure rapid disengagement.

NOTE: Because of the necessary movement of the air

chamber and Air Line upon engagement, flexible

tubing or air lines must be used on the Air Champ

II.

Due to bearings seal drag, the outer portion or the Air

Champ II will rotate when it is engaged. Rest the air line

against a support that is parallel to the centerline of the Air

Champ II to stop this rotation.

NOTE: Pressure should be regulated to the minimum

required for sufficient torque to maximize bearing

life.

nOTe

For quick response, nexen recommends a quick exhaust

valve and short air lines between the Control Valves and

the product. Align the air inlet ports to a down position

to allow condensation to drain out of the air chambers

of the product.

CAUTION

Low air pressure will cause slippage and

overheating. Excessive air pressure will

cause abrupt starts and stops, reducing

product life.

All Nexen pneumatically actuated devices require clean

and dry air, which meet or exceeds ISO 8573.1:2001

Class 4.4.3 quality.

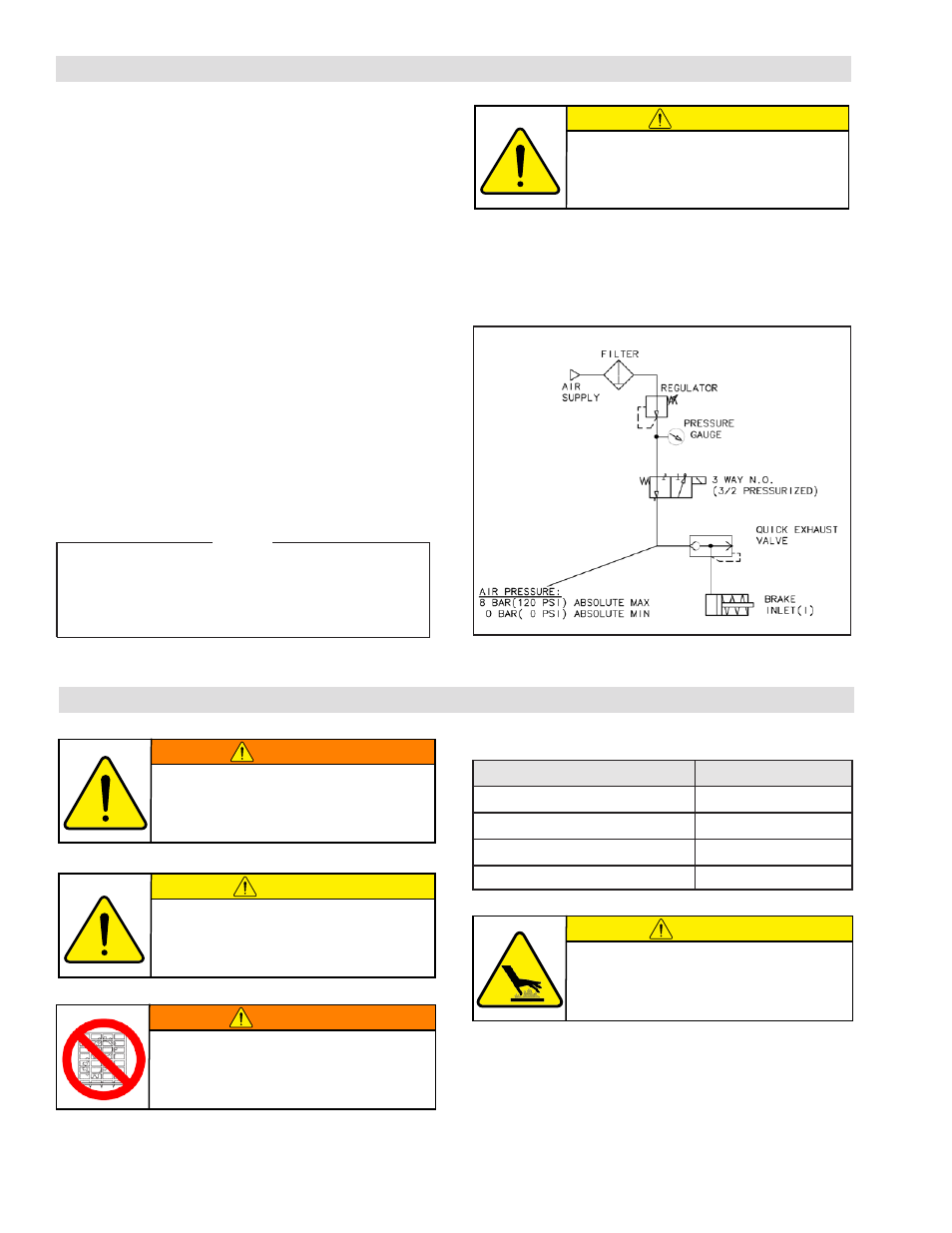

The following is a common air supply scheme used with

this product. This is an example and not an all-inclusive

list. All air circuits to be used with this product must be

designed following EN983 guidelines.

OPerATIOn

WARNING

Never exceed maximum operating

speeds listed for your product.

(See Table 6).

CAUTION

The temperature limits for this

product line are 4.5-100 Degree

Celsius (40-220 Degree F).

CAUTION

Never exceed life of facing material. Facing

life depends on the volume of material and

the total energy over the life of the unit.

Expected life (in hrs) can be found by:

Time=Volume/(Power*Wear Rate).

TABLe 6

Size

Max rPM

F-450

3,600

L-600

3,600

M-800

1,800

H-1000

1,800

WARNING

Ensure proper guarding of the product is

used. Nexen recommends the machine builder

design guarding in compliance with OSHA 29

CFR 1910 “Occupational Safety and Health

Hazards”.

- M-800 807682 M-800 807680 L-600 805280 F-450 802880 M-800 950256 H-1000 950357 H-1000 950350 H-1000 950355 H-1000 950354 H-1000 950353 H-1000 950361 H-1000 810052 H-1000 810068 H-1000 810042 H-1000 810032 H-1000 810050 H-1000 810055 H-1000 810040 M-800 950250 M-800 950258 M-800 950253 M-800 950254 M-800 950261 M-800 950257 M-800 950255 M-800 807650 M-800 807668 M-800 807655 M-800 807620 M-800 807610 M-800 807640 M-800 807630 M-800 807651 M-800 807663 M-800 807621 M-800 807611 M-800 807641 M-800 807631 M-800 807643 M-800 807652 M-800 807661 M-800 807622 M-800 807612 M-800 807642 M-800 807632 F-450 950051 L-600 950155 M-800 950252 L-600 950154 L-600 950151 L-600 950150 L-600 950162 L-600 950163 L-600 950156 H-1000 950351 F-450 950055 L-600 950158 L-600 950159 L-600 805272 L-600 805262 L-600 805252 L-600 805242 L-600 805232 L-600 805222 L-600 805212 L-600 805292 L-600 805270 L-600 805275 L-600 805260 L-600 805250 L-600 805240 L-600 805230 L-600 805220 L-600 805210 F-450 950052 F-450 950050 F-450 950063 F-450 950062 F-450 950061 F-450 802852 F-450 802842 F-450 802832 F-450 802822 F-450 802812 F-450 802850