Nexen PRD750 966901 User Manual

Page 7

7

FORM NO. L-21265-B-0312

INSTALLATION INSTRUCTIONS

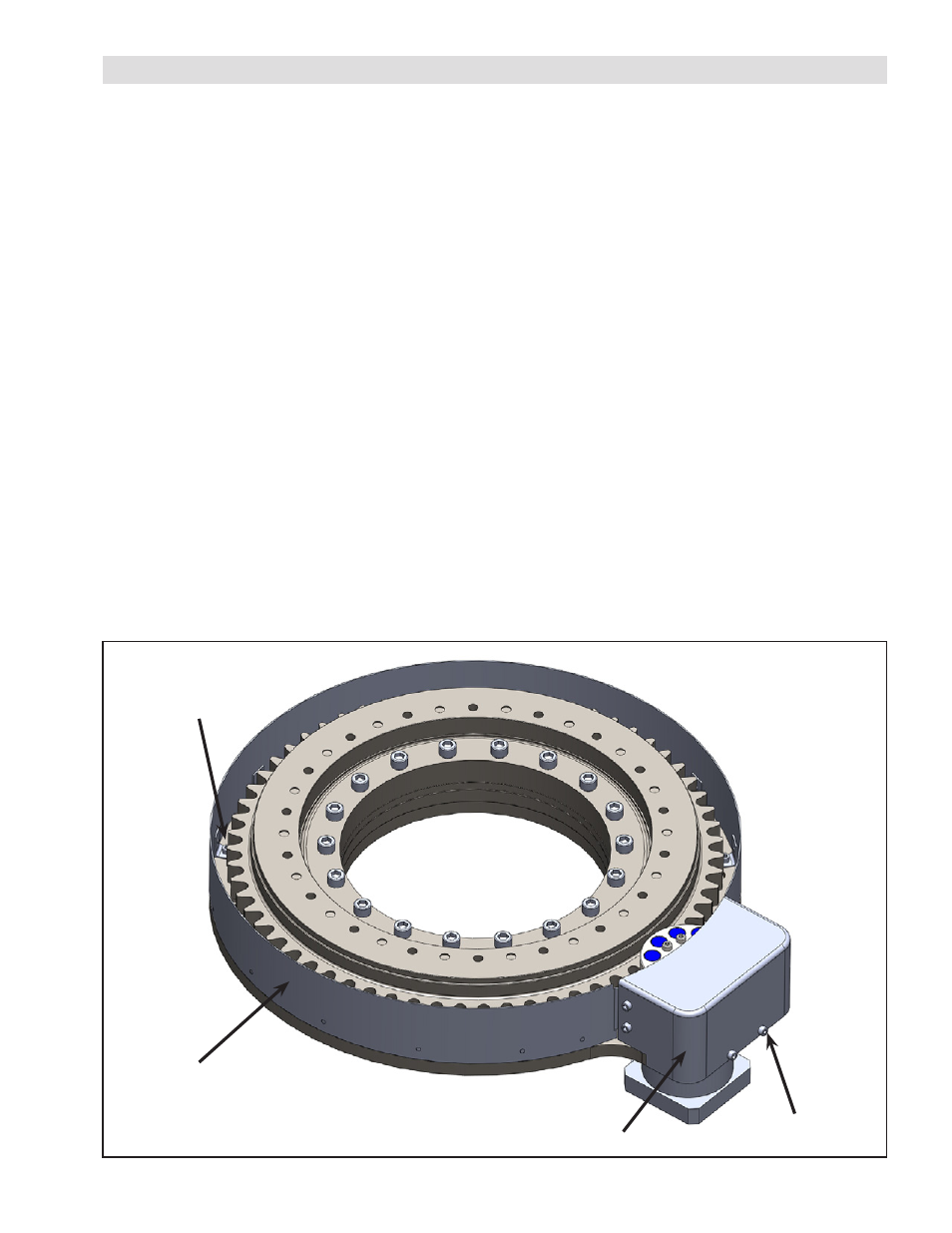

Ring Drive Mounting

Nexen recommends removing the guards before

installation. The mounting holes are accessible thru the

guard, but removing the guard will make the process

easier.

1. First remove the pinion guard by removing the six

M6 fasteners. See Figure 2.

2. To remove the gear guard, the multiple M6 fasteners

are accessible around and between the gear teeth

from the top. See Figure 2. Take extreme caution

near the gear teeth as they may be damaged by

contacting them with a tool.

3. Position the ring drive on the customer supplied

mounting surface. The size 400 can be lifted using

the threaded holes used to mount the dial plate. The

size 750, 1100 and 1500 have a pattern of M12

threaded holes on the inner race of the bearing that

can be used to lift the product.

4. Once the Ring drive is in location, install the M12

mounting bolts to secure to the mounting surface.

Tighten the bolts in a star pattern to ensure even

distribution of load. Nexen recommends using

grade 12 bolts for any application, although it is the

customer’s responsibility to ensure the mounting is

suitable for the system loads.

5. Reinstall the gear guard followed by the pinion

guard.

Motor Mounting

The motor mounting depends on the motor/gearbox

combination being used; please refer to the gearbox

manufacturer’s mounting instructions (included with

this document).

Dial Plate Mounting

The dial plate is designed to be piloted by a series of

dowel pins installed in the plate and that straddle the

male pilot on the ring drive. Drawings are available for

each specific size, which will aid in understanding the

method of piloting the dial plate.

The dial plates should be mounted using all available

holes. Again, tighten in a star pattern to ensure even

load distribution. It is the responsibility of the customer

to ensure the bolt grade and qty is sufficient for the

application.

Figure 2

Gear Guard

Fasteners

Gear Guard

Pinion Guard

Pinion Guard

Fasteners