Nexen HG25 969043 User Manual

Page 6

FORM NO. L-21276-B-1213

6

I

nstallatIon

of

HG

to

M

acHIne

f

raMe

1. Before installing the HG into the machine frame:

a. Wipe the HG pilot and mounting face clean. Wipe

the internal pilot and HG mounting face of the

machine frame.

b. Apply a serviceable thread locking compound to

the threads of the HG mounting screws.

c. Gently guide the HG into the machine frame.

Install HG mounting screws, using a star pattern

while tightening to the torque values shown in

Table 1. These screws should be tightened to

25% of this value in the first iteration of the star

pattern, 50% in the second iteration, and 100%

in the final iteration.

HG OPERATION

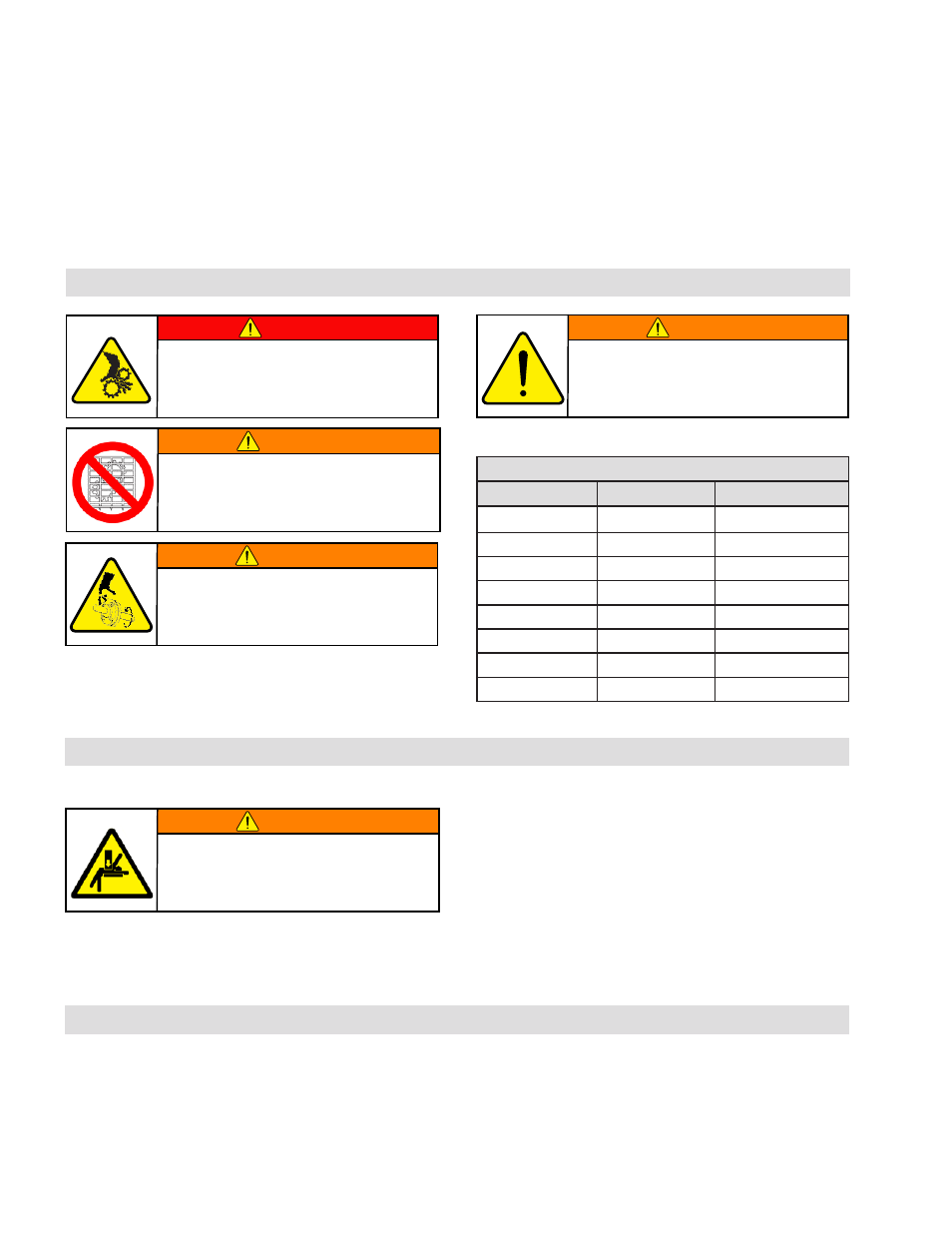

DANGER

This product has moving parts that

can crush or cut appendages. Provide

adequate spacing or guarding from any

operating product.

WARNING

Use appropriate guarding for rotating

components. Failure to guard could

result in serious bodily injury.

WARNING

Ensure proper guarding of the product is

used. Nexen recommends the machine builder

design guarding in compliance with OSHA 29

CFR 1910 “Occupational Safety and Health

Hazards”.

WARNING

Never exceed maximum operating

speeds listed for your product. (See

Table 2).

TABLE 2

DISENGAGING AND REMOVAL OF THE HG

1. De-couple the load from the HG.

2. Disconnect the power source, ensuring that no torque

can be applied to the HG.

3. The motor/HG mechanism assembly can then be

disassembled from the machine, following the reverse

order of assembly steps.

4. If the motor is to be disassembled from the HG, it will

be necessary to direct a flashlight beam into the clamp

collar access hole in order to align the clamp collar

screw so that the hex key can easily be re-engaged to

loosen it. The HG will need to be slowly backdriven

so that the input rotates to achieve this alignment.

WARNING

Failure to properly support the load

before disengaging the HG could

cause serious harm to operators or

equipment.

LUBRICATION

The gearcase of the HG has been filled with a high quality

synthetic extreme pressure grease and is considered to

be “lubed for life”. It is not recommended, therefore, that

the geared pinion be field-serviced. Contact Nexen in the

event that the HG requires maintenance.

The HG can be mounted in any orientation and requires

no special provisions for sealing or venting when

operating within the recommended ambient temperature

range of -5 to 40° C (23 to 104° F). Contact Nexen for

applications requiring the HG to operate outside of this

temperature range.

Harmonic Gearhead Maximum Speeds

Product / Ratio

Motor RPM

Output RPM

HG17 / 50:1

7300

146

HG17 / 80:1

7300

91

HG17 / 100:1

7300

73

HG17 / 120:1

7300

61

HG25 / 50:1

5600

112

HG25 / 80:1

5600

70

HG25 / 100:1

5600

56

HG25 / 120:1

5600

47