Hg requirements, Hg installation – Nexen HG25 969043 User Manual

Page 5

5

FORM NO. L-21276-B-1213

HG REQUIREMENTS

• The HG can be mounted in any orientation, however must meet the recommended mounting specifications found

later in this document.

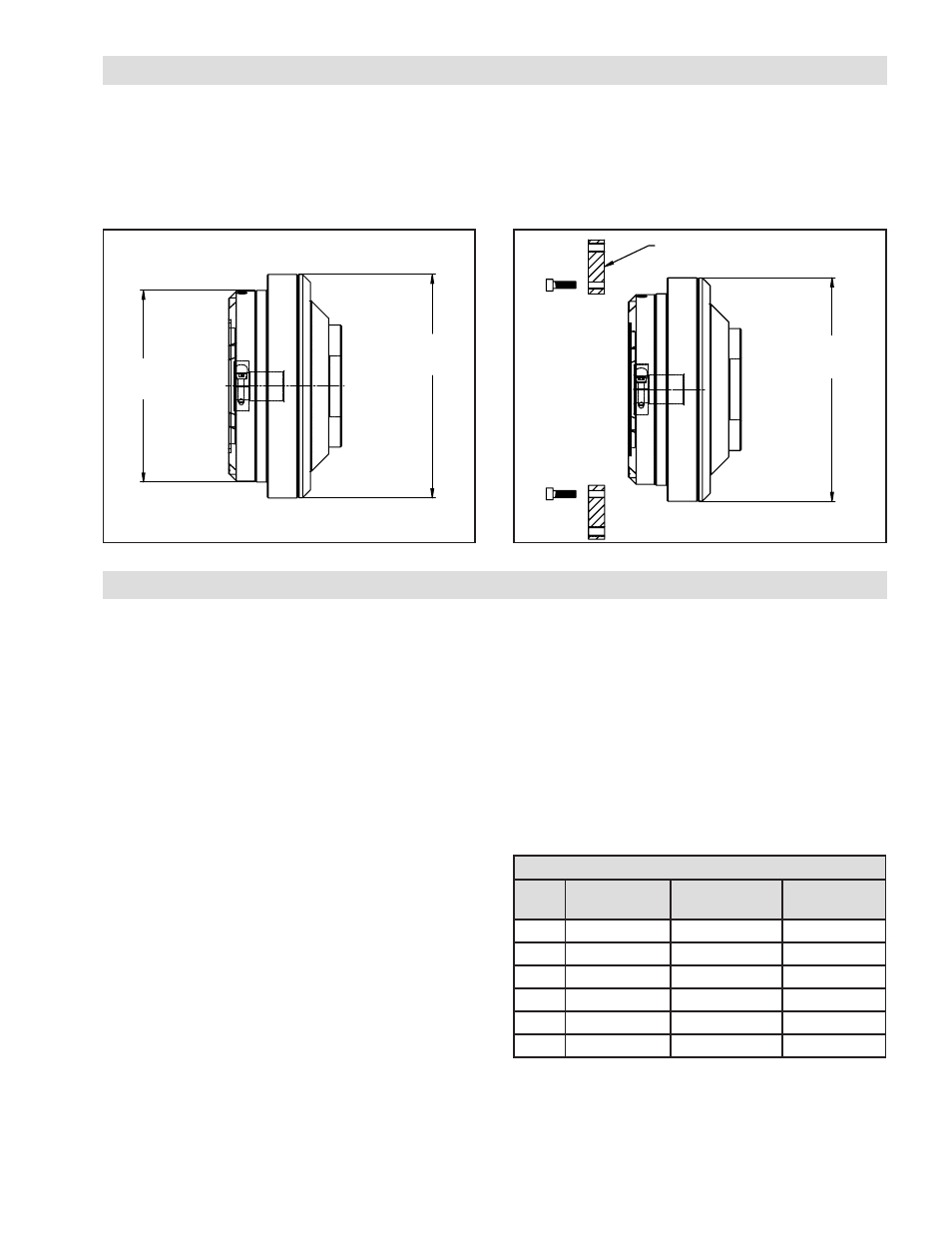

• There are two pilot options on the HG product. If using the primary mounting pilot the product can be mounted

directly to the machine frame or pre-loader. If the secondary mounting pilot is desired, it will require a transition plate

as shown below.

PRIMARY

MOUNTING

PILOT

SECONDARY

MOUNTING

PILOT

Figure 1

SECONDARY

MOUNTING

PILOT

FRONT MOUNT APAPTOR RING

Figure 2

The order in which the HG is assembled to the motor and

machine is not critical, and should be done in whichever

order provides for the least amount of difficulty to the

machine assembler.

I

nstallatIon

of

M

otor

to

HG

1. Before installing the motor into the HG:

a. Wipe the motor shaft, pilot, and mounting face

clean. Wipe the internal pilot and motor mounting

face of the HG clean.

b. Ensure that the HG’s clamp collar is positioned

over the slotted portion of the motor shaft bore

such that the slots do not line up.

c. Remove clamp collar access set screw.

d. Insert the long blade of a hex bit (included) through

the clamp collar screw access hole in the motor

adapter and engage with the clamp collar screw

head.

2. Apply a serviceable thread locking compound to the

threads of the motor face mounting screws and a thin

film of anti-sieze compound to the motor shaft.

3. Slowly and gently guide the motor into the input of the

HG. During this part of the procedure, the weight of

the motor should be adequately supported. Never

allow the motor to be suspended from HG until the

shaft and pilot diameter are fully inserted.

4. Once the motor shaft and pilot are fully seated within

the HG input, tighten the motor face mounting screws

according to Table 1. After the motor face screws are

tightened the clamp collar screw can be tighten, also

according to Table 1.

HG INSTALLATION

Motor Fasteners

Size

HG Mounting

Screw Torque

Motor Mounting

Screw Torque

Clamp Collar

Screw Torque

17

32 in-lbs

28 in-lbs

18 in-lbs

25

32 in-lbs

28 in-lbs

18 in-lbs

Table 1

5. Once motor has been fully assembled to HG, remove

the hex bit from the clamp collar access hole and save

for future disassembly needs.

6. Reinstall clamp collar access set screw.