Brake assembly – Nexen SBPA05 964950 User Manual

Page 10

FORM NO. L-21067-C-0813

10

BRAKE ASSEMBLY

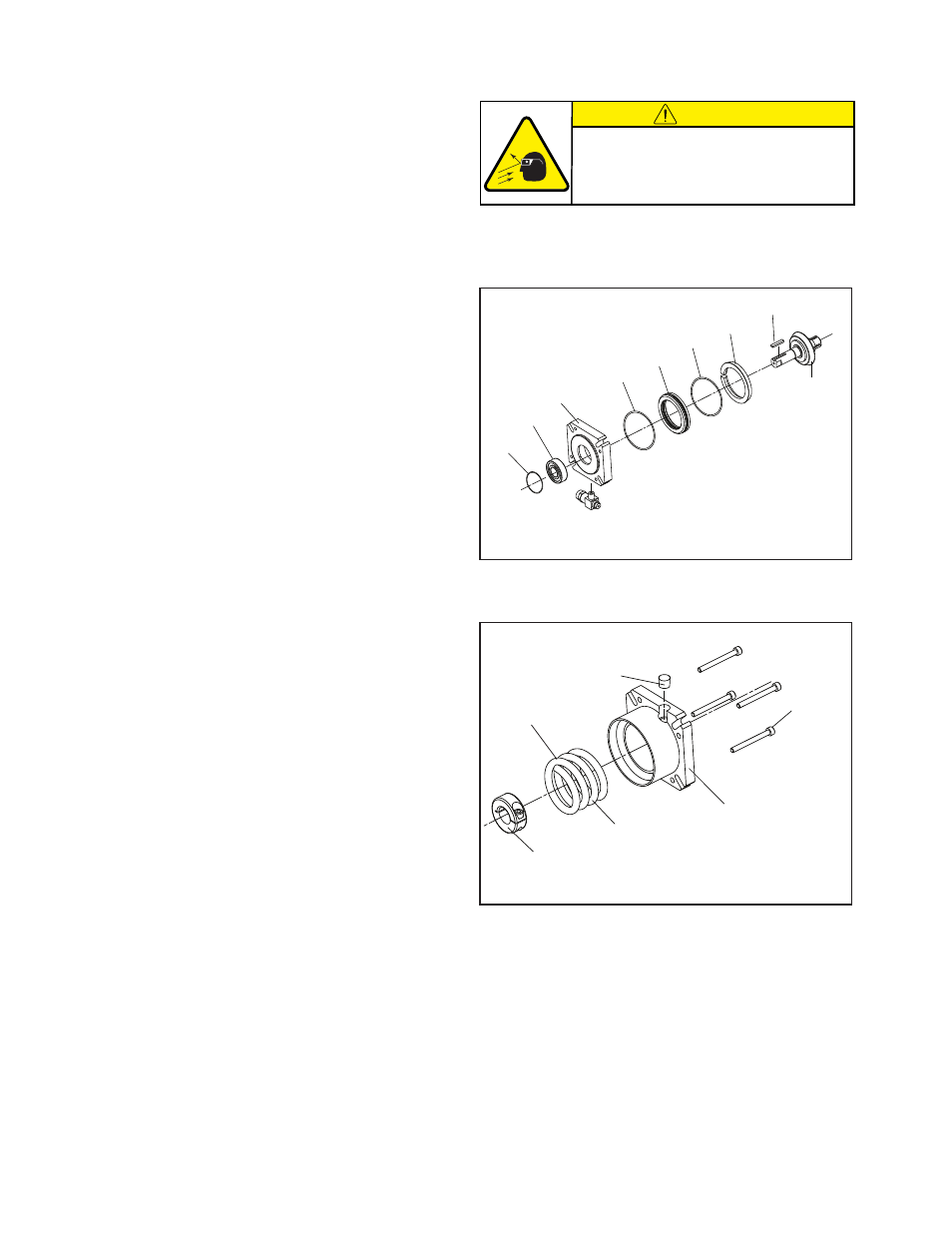

NOTE: Refer to Figures 7 & 8.

1. Alternately and evenly, remove the four Socket Head

Cap Screws (Item 11) and separate the Air Chamber

(Item 6) from the Input Flange (Item 10).

2. Remove the Output Shaft (Item 1) from the Ball

Bearing (Item 2) by pressing in on the output shaft.

3. Remove the Piston (Item 5) from the Air Chamber (Item

6). You may need to apply compressed air to the air

inlet to remove the Piston.

4. Remove the old O-ring Seals (Items 3, 4) from the

Piston.

5. Remove the Retaining Ring (Item 21) and press the

Bearing (Item 2) out of the Air Chamber (Item 6).

6. Clean the bearing bore of the Air Chamber (Item 6)

with fresh solvent, removing old Loctite®.

7. Apply a continuous bead of Loctite® 680 around

the inner circumference of the Air Chamber (Item 6)

bearing bore.

8. Carefully align the outer race of the new Bearing (Item

2) with the bore of the Air Chamber (Item 6).

9. Supporting the Air Chamber (Item 6) and pressing on

the outer race of the new Bearing (Item 2), press the

new Bearing into the Air Chamber.

10. Visually inspect the inner diameter grooves and the

outer diameter grooves of the Piston (Item 5) for

debris. Clean as necessary.

11. Reinstall the retaining ring.

12. Coat the O-ring contact surfaces of the Air Chamber

(Item 6), the Piston (Item 5), and the O-ring Seals

(Items 3, 4) with a thin film of O-ring lubricant and

install the new O-ring Seals.

13. Slide the Piston (Item 5) into the Air Chamber

(Item 6).

14. Clean the friction surface of the Input Flange and

Output Shaft (Item 6) with solvent.

FIGURE 7

FIGURE 8

(continued...)

SIZES 2, 3, 4, 5

Fused End

*Size 2 Only

Item 6

Item 5

Item 3

Item 2

Item 8

Item 4

Item 20

Item 1

Item 23

Item 21

Item 11

Item 10

Item 9

Item 7

Item 14

CAUTION

Working with spring or tension loaded

fasteners and devices can cause injury.

Wear safety glasses and take the

appropriate safety precautions.