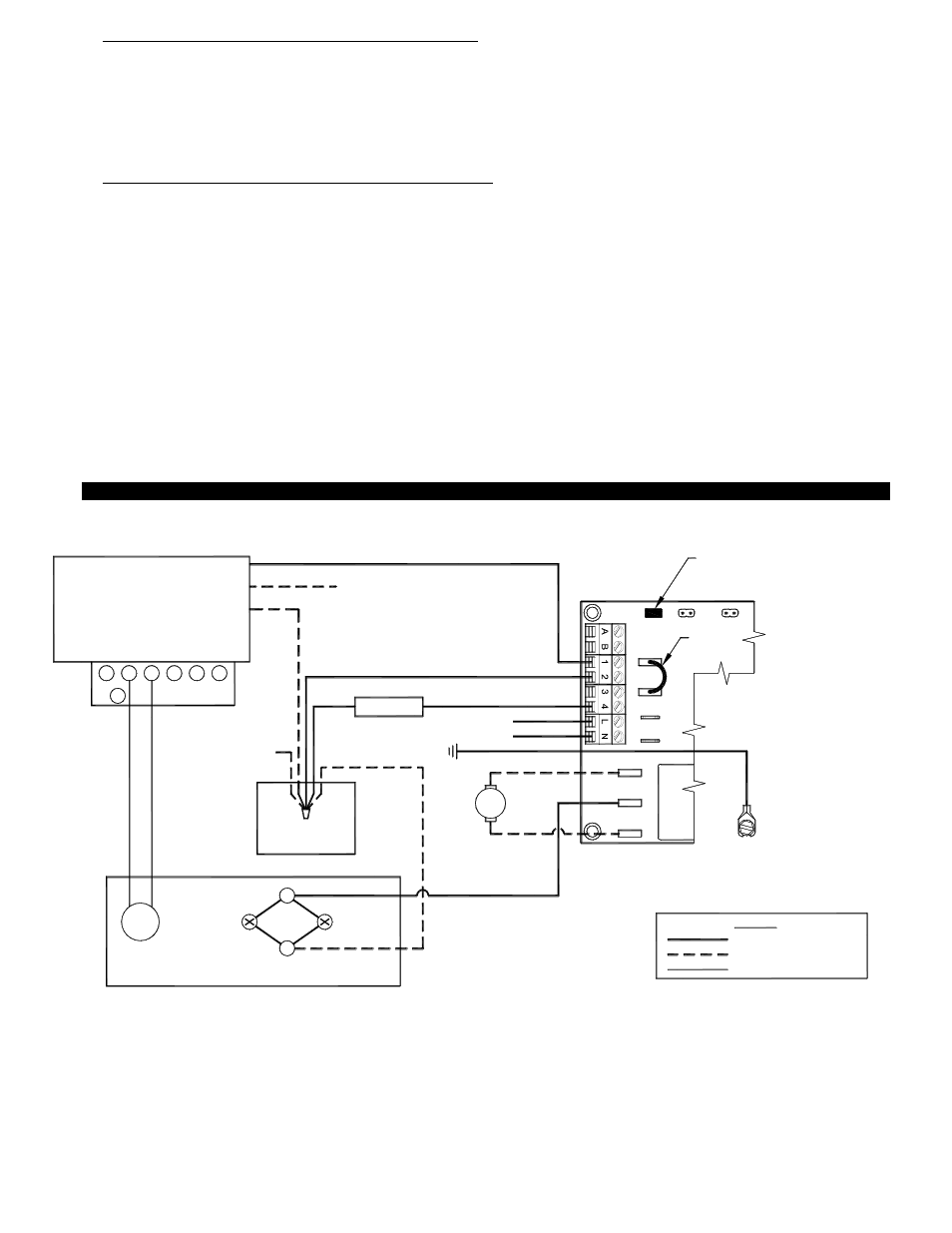

Diagram q – Tjernlund SS1R SideShot (Discontinued) with UC1 Universal Control (Version X.06) 8504117 Rev B 02/06 User Manual

Page 13

For "F" series oil furnaces (-OBF-XXX, -OPF-XXX & etc.): Drill a 1" diameter hole into the junction box side of the furnace

wall, allowing for adequate clearance from electrical components. (Do not drill the hole at or near the junction box.) Use caution

when drilling into the furnace so existing wiring and components are not damaged. The five wires connecting the Rheem, Ruud

or Weatherking oil-fired furnace to the SS1R power venter must be routed through this new hole. When the hole is complete,

install a 1" diameter bushing. Some wires will route to the burner junction box and some will route to the main junction box on

the furnace wall. If electrical conduit is not going to be used to the junction boxes, then a mechanical strain relief must be used

where wires pass into the junction boxes (Note: There may be additional room in the existing strain relief(s) of the junction

boxes to add additional wires. Check the specifications for the strain relief.).

5. For "D"(-OBD-XXX, -OPD-XXX and etc.) series oil furnaces, remove the wire-nuts which secure the Orange to Black wires

(burner control) and White wires (line neutral) of the primary control (see Diagram Q).

A.

In addition to the L1, Neutral and ground that must be supplied to the SS1R UC1 control board, four wires are to be

installed from the oil furnace to the SS1R Side Wall Vent System. Refer to Diagram Q and instructions below for wiring.

B.

Attach L1 (115V) and Neutral wires from a nominal 115VAC power source to L & N on the UC1 control board. This power

should be routed through a disconnect so that power to the SS1R can be turned off remotely if necessary. Additionally, all

wire should be run through the appropriate conduit per NEC standards as noted in step 1.

C.

A ground wire will need to be installed between the system ground and the grounding lug in SS1R electrical box.

D.

A neutral wire will need to be installed from the oil furnace line neutral to the terminal labeled "2" on the UC1 control

board. Note: The existing wire nut (which connects all the line neutrals together) is full and a new wire cannot be added

to it. A new (larger) wire-nut will have to be installed and this will require that the neutral wire is cut and stripped.

E.

Route a wire to connect the orange lead on the primary furnace control to the UC1 control board terminal labeled "1".

F.

Last, route a wire between the Beckett burner motor and ignition transformer to the UC1 control board terminal labeled "M".

G.

The RED Voltage Jumper on UC1 board in SS1R must be in the 115V position.

12

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

C

F

F

R

W

G

Y

WHITE

BLACK

ORANGE

BECKET BURNER

TO BURNER

MOTOR

BLACK

B / W

TO FUSE

DISCONNECT

YELLOW

YELLOW

NEUTRAL

JUNCTION BOX

TO FACTORY-WIRED

LIMIT SWITCHES

VIA JUNCTION BOX

GROUNDED

LEGEND:

LOW VOLTAGE

115 VAC, FIELD-WIRED

115 VAC, FACTORY-WIRED

VENTER MOTOR

(FACTORY-WIRED)

SENSOR

TO IGNITION

TRANSFMR

OIL VALVE

IMPORTANT:

XL

J1

J2

115V

DRY

24V

D/N 9183047-5

CALL

JUMPER

PRIMARY CONTROL

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

UNIV

E

R

S

A

L CO

NT

RO

L

XN

TO FLAME

NM

T

R

M

DIAGRAM Q

FIELD WIRING TO RHEEM, RUUD, OR WEATHERKING -OBD-XXX & OPD-XXX MODEL OIL BURNING FURNACES