Tjernlund HS3,4,5 Series with UC1 Universal Control (Version X.02) 8504111 Rev 09/02 User Manual

Page 10

9

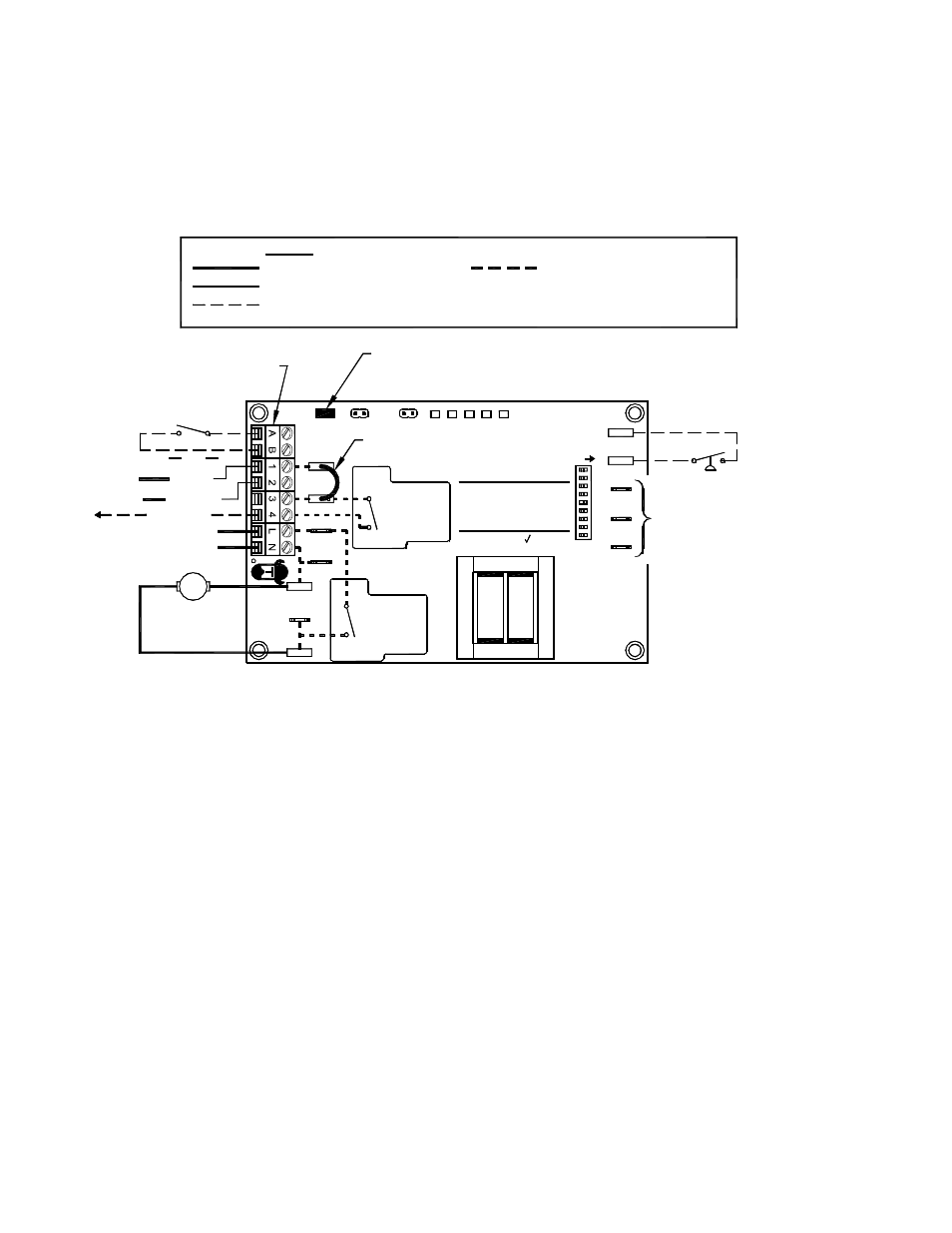

WIRING CONNECTIONS FROM UC1 UNIVERSAL CONTROL AND MOTOR MADE IN FAN PROVER JUNCTION BOX

The UC1 has a 2 foot whip that contains a ground lead and the leads to power the Venter motor and connect to the Fan Prover. If it

is desirable to mount the UC1 more than 2 feet from the Fan Proving Switch an additional electrical junction box and appropriate

length of conduit will be necessary. Any added wire should be 14 gage and a pig tail should be added to each ground wire connec-

tion so that each electrical junction box is grounded. See diagram on page 8 for a typical UC1, Fan Prover and Venter installation.

WIIRING CONNECTIONS FROM UC1 TO FAN PROVER AND VENTER MOTOR

MODELS HS4 & HS5 (ONLY)

Connect Black and White motor ring terminal leads to ring terminal studs on motor. Connect Ground Lead to ground screw on motor.

IMPORTANT: Motor should be factory wired for proper rotation. As viewed from the opposite end of the shaft (rear of motor), the

motor should rotate clockwise. See motor nameplate for proper rotation.

ALL MODELS (See diagram on page 8 for typical installation)

1. Connect ground wire from UC1 whip and Venter motor ground wire to ground screw in Fan Prover junction box.

2. Connect Black and White motor leads from UC1 whip to Venter motor leads in Fan Prover junction box.

3. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals. Leads are not polarity sensitive.

MULTIPLE APPLIANCE INTERLOCKS

To interlock with one additional 24/115 VAC heater add the MAC1E. It is a stripped down auxiliary board version of the UC1 and is

powered by and communicates with the UC1 through a factory wired whip.

To interlock more than two 24/115 VAC heaters, add the MAC4E for a total of up to 5 heaters. It is powered by and communicates

with the UC1 through a factory wired whip.

To interlock a millivolt water heater and a 24/115 VAC furnace or boiler, add the WHKE and MAC1E.

MILLIVOLT INSTALLATIONS

Each millivolt appliance interlocked with the UC1 must have its own WHKE kit installed. The WHKE Gas Pressure Switch actuates the

Venter through the A - B Dry contacts. The Linear Limit switch disables the heater in the event of a venting malfunction. IMPORTANT:

Each millivolt appliance interlocked with the UC1 must have its own Linear Limit spill switch.

IMPORTANT:

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

CALL

RELAY

INTERLOCK

COMMON

NEUTRAL

PRODUCTS,

INC.

MOTOR

1 H.P. MAX @ 115 VAC

SUPPLY

115 VAC

50/60 Hz

R

TJERNLUND

9183006

NO

MTR

M

MOTOR

RELAY

N

COM

NO

115 VAC

24 VAC

D/N 1303958-1

DO NOT SUPPLY VOLTAGE

TO "A" OR "B".

DO NOT SUPPLY POWER!

5 VDC BOARD-GENERATED POWER

HOT

24 VAC

USER-PROVIDED

CALL SWITCH

LINE

OR

"DRY"

OR

115V

J2

COM

24V

DRY

LEGEND:

115 VAC

5

POST-PURGE SETTINGS

FOR TJERNLUND

TO P1, P2, C, GND

AUXILIARY

OR F. DOING SO

WILL DAMAGE THE

CONNECT POWER

OPEN PROVER OPTION

(9)

(3 - 8)

9

7

8

6

CONTROL.

DEVICES. DO NOT

F

GND

ON

LED1

PRE-PURGE SETTINGS

LED5 LED4

LED2

LED3

(1 - 2)

2

4

3

1

C

P1

P2

PROVER

J1

XL

XN

115 OR 24 VAC FROM CALL JUMPER

OR USER-PROVIDED VOLTAGE

FROM TERMINAL 3 TO 4 WITH CALL

JUMPER REMOVED

K2

K1

APPROVED

MAC1E OR MAC4E

JUMPER

RED

RED

GREEN

GREEN

AMBER

WARNING: Disconnect power supply from the UC1 and heating equipment when making wiring connections and servicing the

Venter. Failure to do so may result in personal injury and/or equipment damage. LED #5 (RED) should be off with

power removed.

UC1 UNIVERSAL CONTROL WIRING SCHEMATIC

The Ground lead, Venter motor and Fan Prover leads are factory connected to the UC1 circuit board. Venter Ground, motor and Fan

Prover wiring connections are made at the free end of the 2 foot whip. Motor should be factory wired for proper rotation. As viewed

from the opposite end of the shaft (rear of motor), the motor should rotate clockwise. See motor nameplate for proper rotation.