Tjernlund HS3,4,5 Series with UC1 Universal Control (Version X.06) 8504111 Rev C 07/05 User Manual

Page 15

12

UC1 UNIVERSAL CONTROL OPERATIONAL CHECK

1. Confirm power is supplied to the Control. LED #6 (RED) should be on.

2. Activate the UC1 by initiating an appliance call for heat. LED #1 (AMBER) should be on.

3. The motor relay will close and activate the Venter motor. LED #3 (GREEN) should be on and

Venter motor should be running.

4. If the safety circuit across P1 & P2 (Venter Prover) is closed, indicating an approved condition, the

appliance interlock relay will close making terminal #3 closed to terminal #4 & LED #2 (BLUE).

Appliance burner should fire.

5. Remove power to the UC1 and any interlocked appliances. The LED #6 (RED) or any LED’s

should not be on. Test the safety circuit by removing the Blue or Yellow Lead from Fan Proving

Switch. Do not let the opened Lead touch a ground or damage may occur to the control when

power is Reestablished. Reestablish power to the UC1 and interlocked appliances and initiate

a call for heat. After 60 seconds a Prover Start Up fault should arise with LED #4 flashing 3 times.

6. Remove appliance call for heat and power to the UC1 and any interlocked appliances. The LED #6

(RED) or any LED’s should not be on. Reconnect Blue or Yellow Fan Prover lead to Fan Proving

Switch terminal removed from in step 5.

7. Reestablish power to UC1 and interlocked appliances and initiate a call for heat to confirm proper operation of UC1 and appliance.

RESETTING FAULT CODE CREATED BY STEP 5 OF OPERATIONAL CHECK

IMPORTANT: Prior to accessing the fault code memory, note the settings of the dip switches so that they can be returned to their

original Pre / Post-Purge positions. When power is supplied to the UC1 use caution when moving dip switches.

The last fault code can be retrieved at any time by setting all dip switches 1-8 to the up, or “on” position. The last fault code, or lack

there of, will be indicated by counting the number of times LED 4 flashes. By moving any of the dip switches back to their original

position, the fault code will be cleared. NOTE: The UC1 board must have its 115 VAC power supply present when any of the (1-8) dip

switches are moved back to their original position for the fault code to clear.

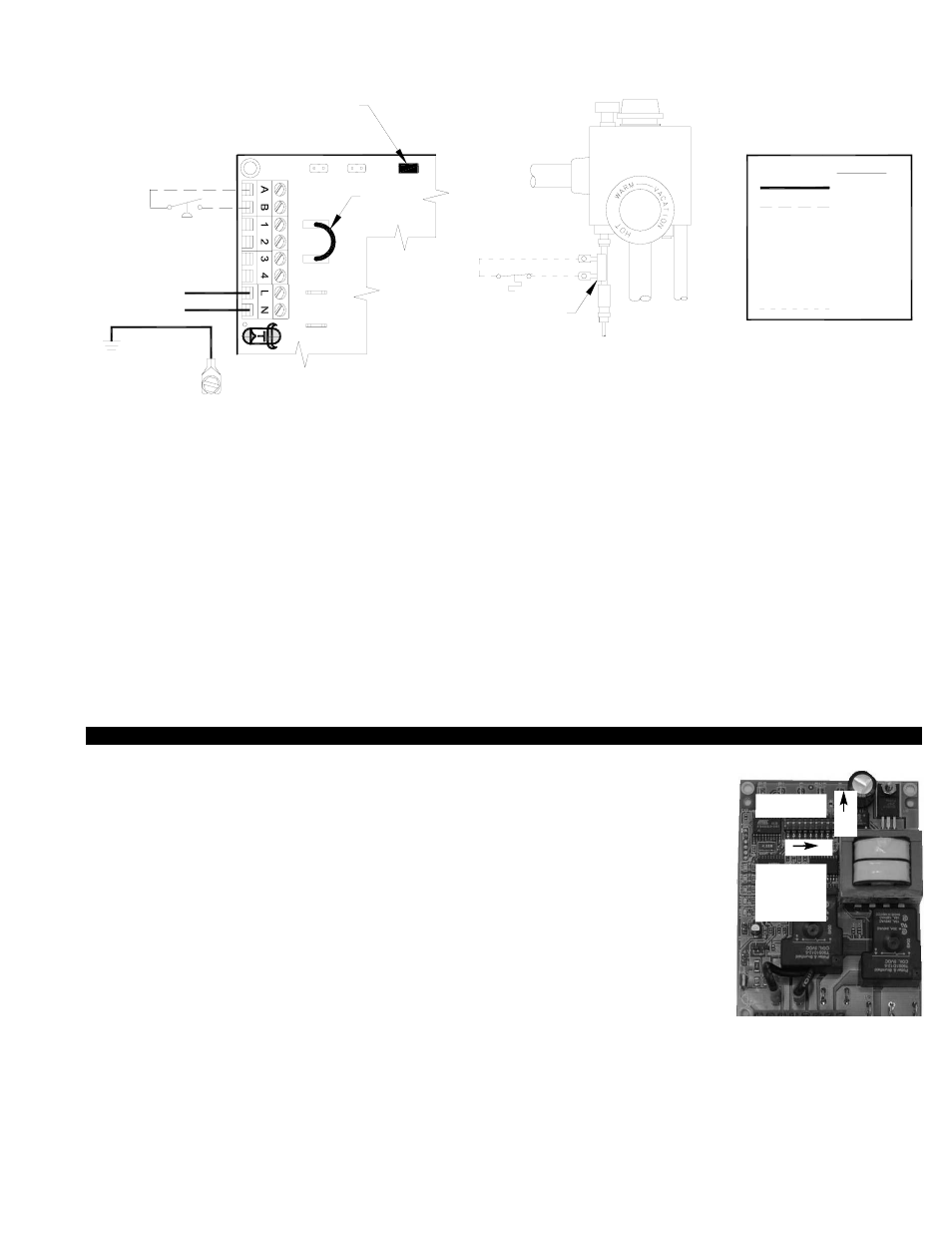

UC1 UNIVERSAL CONTROL AND WHKE INTERLOCK KIT

CONNECTED WITH A MILLIVOLT APPLIANCE

XN

R

UNI

V

E

R

S

A

L CO

NT

RO

LLE

R

D/N 9183046-9

CALL

AS APPLIANCE INTERLOCK VOLTAGE.

RED JUMPER POSITION MUST BE THE SAME

XL

J1

J2

DRY

115V

24V

IMPORTANT:

JUMPER

GENERATED

5 VDC

LEGEND:

115 VAC

WHKE GAS

SAFETY CIRCUIT ACROSS P1 & P2 OF UC1 IS NOT UTILIZED

WITH HEATING EQUIPMENT AS SHOWN.

IN THIS APPLICATION. SPILL SWITCH MUST BE INTERLOCKED

MILLIVOLT

PRESSURE

SWITCH

JUNCTION ADAPTER

THERMOCOUPLE

950-0470 (JA1)

LINEAR LIMIT

SPILL SWITCH

GAS

VALVE

30 MILLIVOLT WATER HEATERS REQUIRE USE OF THE

(ECO) OF WATER HEATER. LINEAR LIMIT SPILL SWITCH,

ON 750 MILLIVOLT (POWER PILE) WATER HEATERS WIRE

LINEAR LIMIT SPILL SWITCH IN SERIES WITH HIGH LIMIT

950-0470 THERMOCOUPLE JUNCTION ADAPTER.

950-0470 JUNCTION ADAPTER AND GAS PRESSURE

SWITCH ARE INCLUDED WITH WHKE KIT.

DO NOT

SUPPLY

POWER.

POWER!

BOARD-

50/60 Hz

SUPPLY

115 VAC

ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING SPADE TERMINAL IN

IMPORTANT:

Each millivolt appliance interlocked with the UC1 must have its own WHKE kit installed. The WHKE Gas Pressure Switch actuates

the Venter through the A - B Dry contacts. The Linear Limit switch disables the heater in the event of a venting malfunction.

IMPORTANT: Each millivolt appliance interlocked with the UC1 must have its own Linear Limit spill switch.

1. Wire WHKE Gas Pressure Switch in series with A and B terminal on UC1. Do not supply voltage to A and B terminals.

2. Wire WHKE Linear Limit in series with thermocouple junction adapter or high limit ECO of water heater.

3. Make sure RED voltage jumper on UC1 is in the DRY position.

4. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

5. If not completed, connect ground from UC1 whip to Venter ground in Fan Prover j-box. Connect Black & White leads from UC1

whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch. Prover Leads are not polarity sensitive.

LED 1 AMBER

LED 2 BLUE

LED 3 GREEN

LED 4 RED

LED 5 RED

LED 6 RED

POWER LED

ON

1 9