Tjernlund HS3,4,5 Series with UC1 Universal Control (Version X.06) 8504111 Rev C 07/05 User Manual

Page 11

8

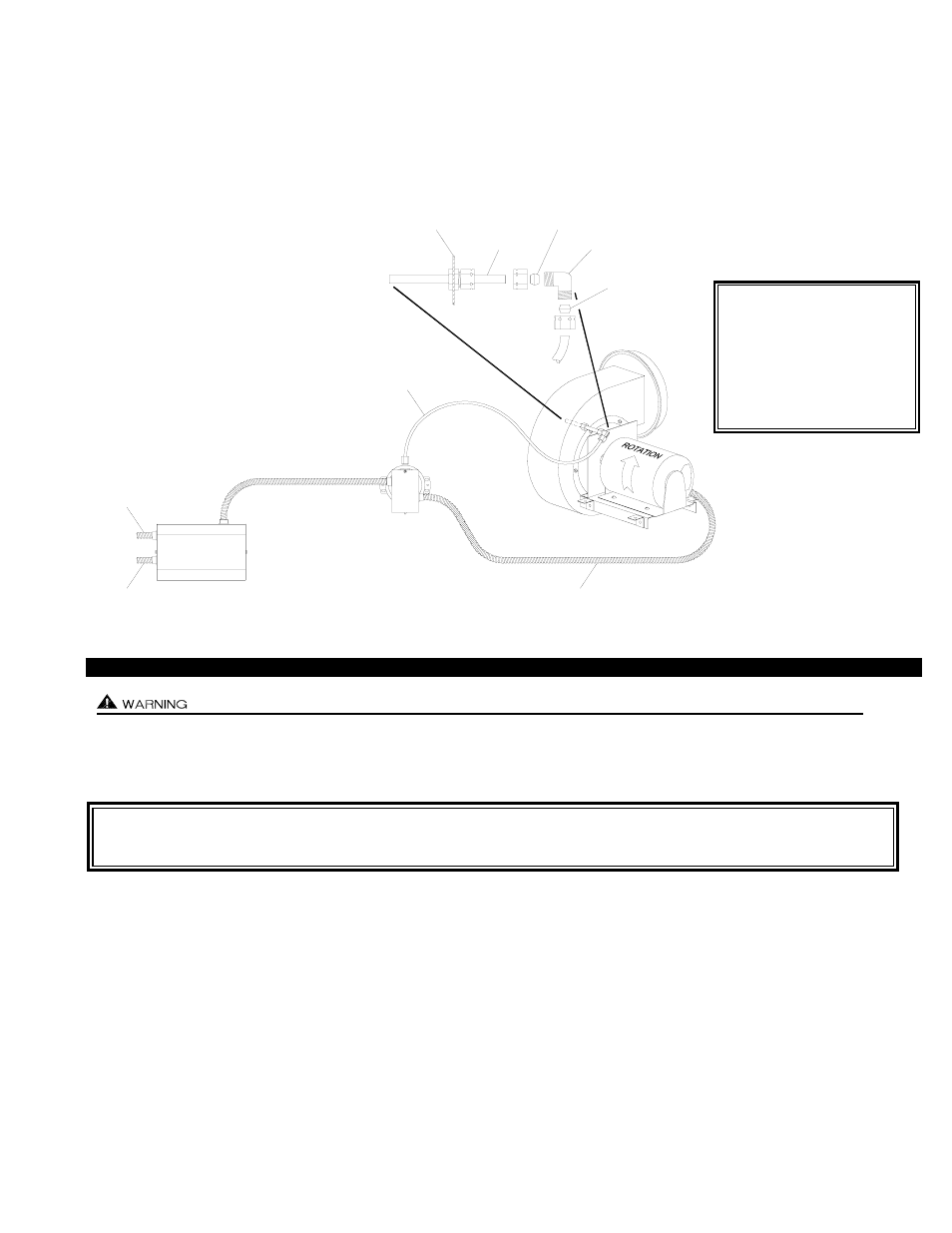

IMPORTANT: The Fan Proving Switch must be mounted so the diaphragm is in a vertical position.

1. Mount Fan Prover in a vertical position within 4 feet of the Power Venter so 5 foot sensing tube can be trimmed if necessary. Do

not mount the Fan Proving Switch on a heat source that exceeds 140oF. Examples of improper mounting surfaces include vent

pipe, venter, top of heater casing or any place where radiant or convective heat would exceed 140oF.

2. Connect the 1/4” aluminum tubing from the Fan Proving Switch to the Power Venter housing using supplied fittings. The factory

calibrated sensing tube length and compression fittings are critical for proper operation of the Fan Proving Switch. If it is necessary

to alter the sensing tube length, ONLY trim sensing tube portion that is on the exterior of the housing. IMPORTANT: DO NOT trim

the sensing tube portion that will be mounted in the interior of the housing because Fan Prover will not sense the proper pressure.

Sensing tube assembly with factory calibrated length must be used for Fan Prover to work properly!

TYPICAL UC1, FAN PROVER AND SENSING TUBE INSTALLATION (DO NOT SUBSTITUTE SENSING TUBE MATERIALS)

WIRING

All wiring from the Venter to appliance must be in compliance with local codes or in their absence, the National Electrical Code (NFPA #70).

All wiring from the UC1 to the appliance must be appropriate Class 1 wiring as follows: installed in rigid metal conduit, intermediate metal

conduit, rigid non-metallic conduit, electrical metallic tubing, Type MI Cable, Type MC Cable, or be otherwise suitably protected

from physical damage.

SEQUENCE OF OPERATION WITH UC1 UNIVERSAL CONTROL AND 24 VAC OR 115 VAC HEATER CONTROL CIRCUIT:

Control signal from thermostat, aquastat, primary control or gas valve is intercepted and routed to terminal “1” on UC1 terminal strip.

When terminal “1” is energized with either 24 VAC or 115 VAC, the Venter motor is energized. After draft is established, the Fan

Proving Switch closes within 5 to 10 seconds energizing terminal “4”, which completes the circuit allowing burner to fire. NOTE: If a

Venter pre-purge is selected, the burner will not fire until the pre-purge time is finished. The Venter will continue to run after the burn-

er has finished firing for the set post-purge time cycle. The UC1 is set for a 2 minute post-purge time period from the factory. See

“Pre / Post-Purge Settings” on page 5 for details.

The "1" input terminal on the UC1 can accept either a 24 VAC or 115 VAC control signal. IMPORTANT: The RED voltage

jumper must be positioned based on appliance interlock voltage 24V or 115V. If using the “DRY” contact activation method, use ter-

minals A & B on UC1 control and position the RED voltage jumper tab in the “DRY” position. See millivolt appliance interlock dia-

gram for further information. IMPORTANT: Only one interlock method (i.e. 24V, 115V or “Dry”) can be used with the UC1. Multiple

appliance interlocks require the use of our MAC-Series multiple appliance controls.

The steps listed under each diagram are intended as a supplement to the diagram. Wiring colors or designations may vary by manu-

facturer. If you are unable to wire per these instructions, call Tjernlund’s Technical Service toll free at 1-800-255-4208 for assistance.

IMPORTANT: If the call for heat interlock signal or 115 VAC power is removed, the UC1 board will reset and any fault, if present, will

be stored in memory instead of displayed. See page 5, “Checking Memory for Last Fault Code”.

IMPORTANT: MORE THAN ONE INTERLOCK METHOD MAY BE APPLICABLE

In many cases it is easier to interlock with the thermostat/aquastat portion of the heater control circuit vs. the ignition module /

primary control portion of the heater control circuit. Review all of the wiring diagram options prior to choosing the best method.

FAN PROVER

VENTER

UC1

5 FT. LENGTH PROVIDED

UNLESS ADDITIONAL CONDUIT,

(MINIMUM 14 GAGE)

2 FT. MAXIMUM LENGTH UNLESS ADDITIONAL CONDUIT,

J-BOX AND WIRE ARE ADDED (MINIMUM 14 GAGE)

INSTALLER-SUPPLIED

115 VAC CONNECTION

BURNER INTERLOCK

CONNECTION

INSTALLER-SUPPLIED

2 FT. MAXIMUM LENGTH

ALUMINUM SENSING TUBE

SIDE OF SENSING TUBE

DO NOT ALTER THIS

HOUSING WALL

SENSING TUBE

ASSEMBLY

SENSING TUBE

COMPRESSION RING

BRASS ELBOW FITTING

COMPRESSION RING

J-BOX AND WIRE ARE ADDED

IMPORTANT: As viewed from the opposite end of the shaft (rear of motor), the motor should rotate clockwise.

IMPORTANT:

Do not connect 5 foot section

of aluminum tubing directly to

Venter housing. Sensing tube

assembly provided with facto-

ry calibrated length must be

used or Fan Prover will not

work properly.