Tjernlund HSJ, 1, 2 Series with UC1 Universal Control (Version X.02) 8504106 Rev 08/02 User Manual

Page 15

14

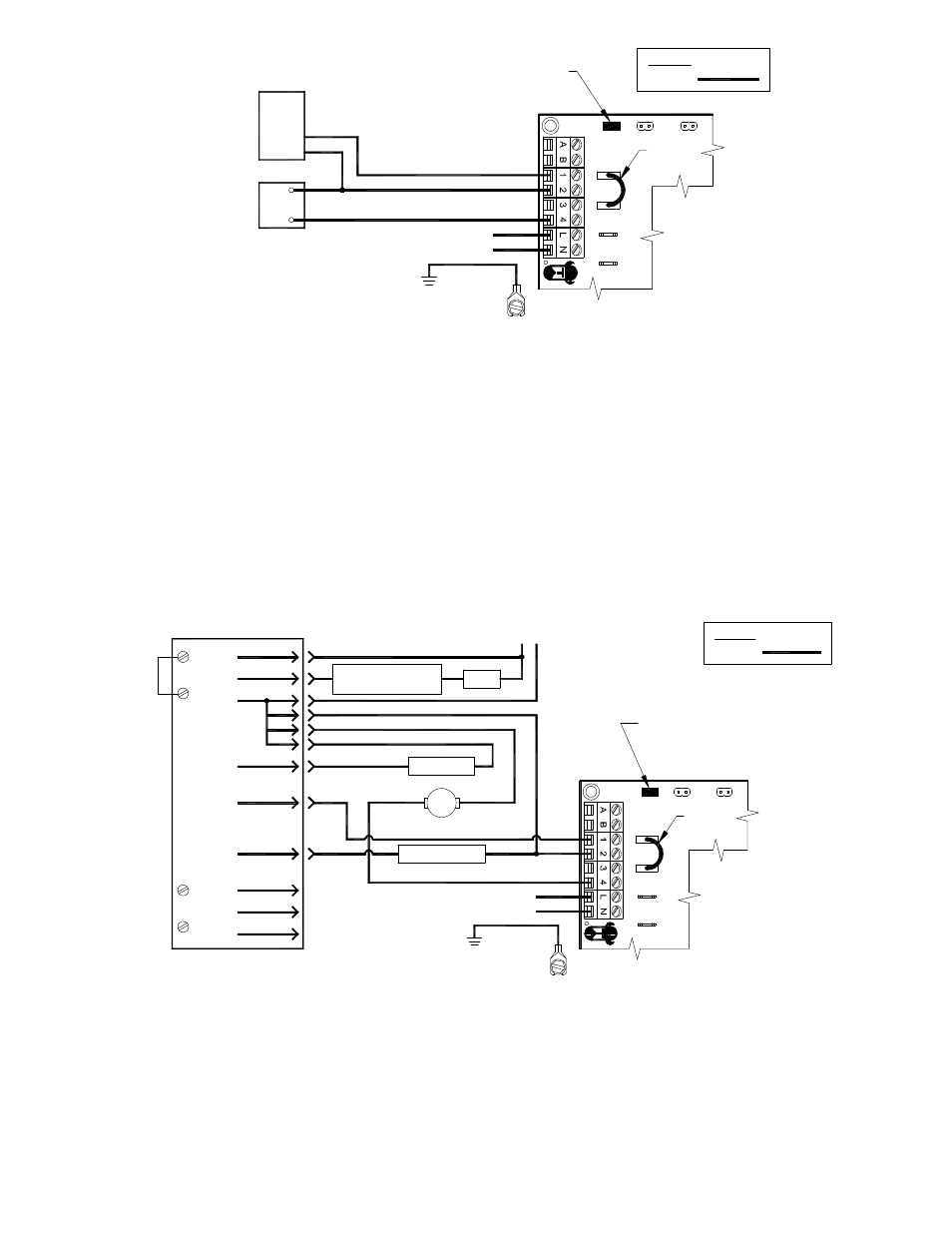

UC1 UNIVERSAL CONTROL CONNECTED TO A HONEYWELL R7184 SERIES OR EQUIVALENT

PRIMARY CONTROL WITH A LINE VOLTAGE THERMOSTAT OR AQUASTAT

Burner

Alarm

Cad Cell

A

Interrupted

Intermittant

Motor

A

IGNITION TRANS

BURNER MOTOR

R

Oil Valve

Limit

R7184

L1

T

T

L2

OIL VALVE

115 VAC

60 Hz

SUPPLY

Limit

24V

DRY

115V

XL

UNIVERSAL CONTROLLER

XN

J1

J2

RED JUMPER POSITION MUST BE THE SAME

AS APPLIANCE INTERLOCK VOLTAGE.

IMPORTANT:

D/N 9183046-6

115 VAC

LEGEND:

CALL

JUMPER

Ignitor

Line Voltage Thermostat

or Aquastat Control

Low Voltage

Jumper

50/60 Hz

SUPPLY

115 VAC

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

1. Disconnect burner motor wire off the R7184.

2. Connect burner motor terminal of R7184 to #1 on UC1 terminal block.

3. Connect #2 on UC1 terminal block to L2 or N.

4. Connect #4 on UC1 terminal block to burner motor wire removed from R7184.

5. Make sure RED voltage jumper on UC1 is on 115V.

6. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

7. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

UC1 UNIVERSAL CONTROL CONNECTED TO A GAS OR OIL BURNER WITH AN AQUASTAT

XN

R

UNIVERSAL CONTROLLER

LINE VOLTAGE OIL BURNER

PRIMARY CONTROL, BURNER

L1

N

XL

J1

J2

115V

DRY

24V

AQUASTAT

B2

B1

C1

C2

L1

L2

D/N 9183046-7

115 VAC

LEGEND:

CALL

JUMPER

RELAY OR GAS VALVE

50/60 Hz

SUPPLY

115 VAC

RED JUMPER POSITION MUST BE THE SAME

IMPORTANT:

AS APPLIANCE INTERLOCK VOLTAGE.

SPADE TERMINAL IN ELECTRICAL BOX.

GROUND

CRIMP GROUND WIRE TO GROUNDING

IMPORTANT:

CAUTION:

WHEN INTERLOCKING WITH AQUASTAT DO NOT DISCONNECT BURNER MOTOR

FROM PRIMARY CONTROL / CAD CELL RELAY.

1. Disconnect B1 from L1 of oil burner primary control, burner relay or hot of gas valve and reconnect to #1 on UC1 terminal block.

2. Connect #2 on UC1 terminal block to B2 or N.

3. Connect #4 on UC1 terminal block to the L1 on line voltage oil burner primary control, burner relay or gas valve.

4. Make sure RED voltage jumper on UC1 is on 115V.

5. Connect 115 VAC supply voltage to L & N terminals on UC1. Crimp Ground wire to grounding spade terminal in UC1.

Important: Installer must supply overload and disconnect protection.

6. If not previously completed, connect ground from UC1 whip to grounding stud in Venter. Connect Black and White leads

from UC1 whip to Venter motor leads. Connect Blue and Yellow leads from UC1 whip to Fan Prover switch terminals in

Venter. Yellow lead should be on switch terminal closest to Venter junction box wall.

NOTE: If burner primary control goes out on lockout, the Venter will continue to run as long as a call for heat is present.