Tjernlund HSJ, 1, 2 Series with UC1 Universal Control (Version X.06) 8504106 Rev C 07/05 User Manual

Page 7

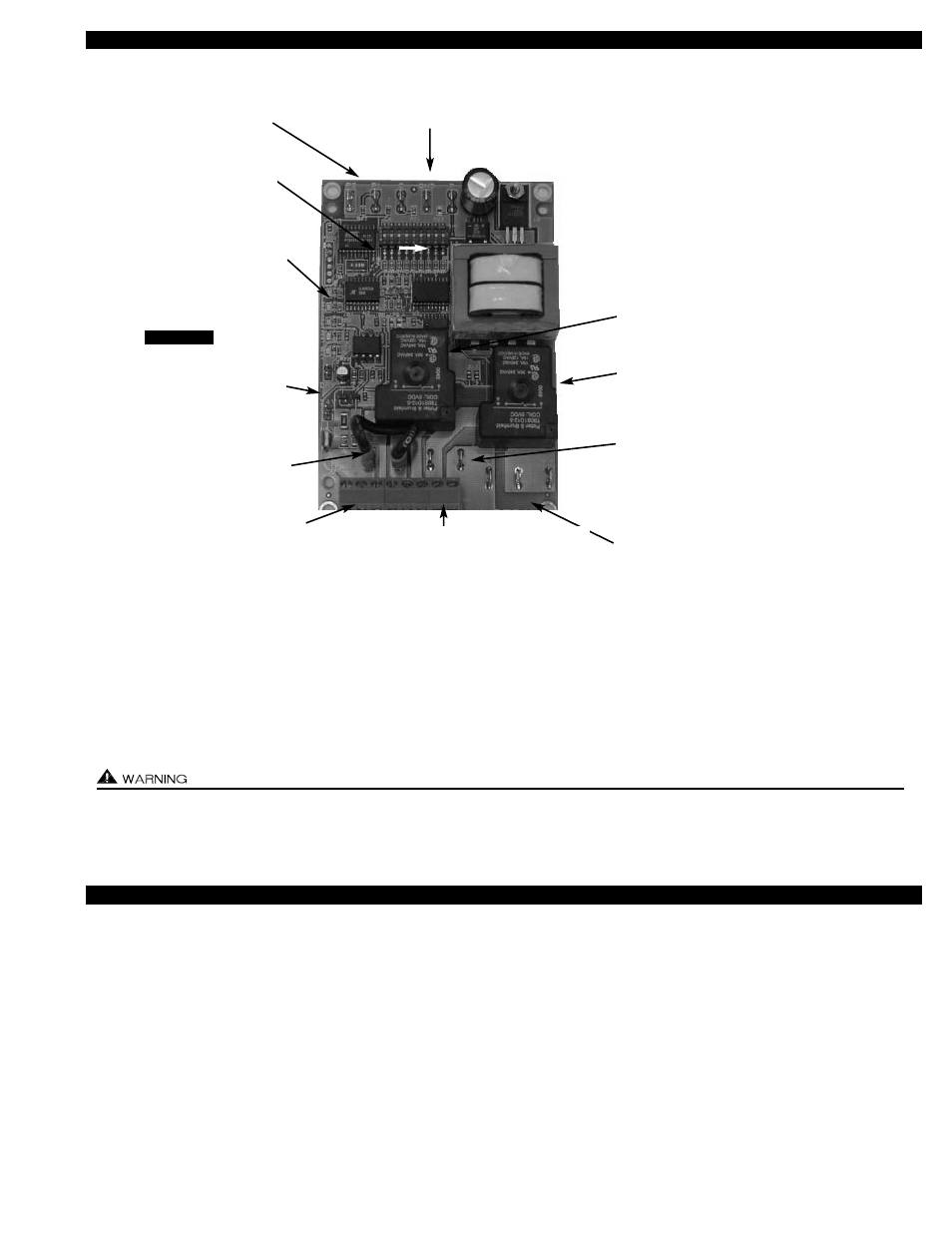

UC1 UNIVERSAL CONTROL BOARD FEATURES

# 1.

Power supplied by board. Do not supply power to this area or control damage may result.

# 2.

Do not supply power to the appliance interlock block with the call selector in the “DRY” position.

Control damage may result if power is supplied.

# 3.

Circuit protection must be provided by the installer. 16 Amps is the maximum current allowed for this device at terminal L.

A 15 Amp circuit breaker is recommended.

VET

I

I

LED STATUS & FAULT INDICATORS

LED INDICATOR LIGHTS

LED #1 (Amber)

Appliance call for heat.

LED #2 (Blue)

Safety circuit through P1 & P2 (Venter Fan Prover). Indicates Venter prover is closed during run cycle.

Burner circuit is energized with Interlock Relay contact closure from terminal 3 to 4.

LED #3 (Green)

Power switched to Venter motor from L to MTR & M.

LED #4 (Red)

Status / Fault indicator.

LED #5 (Red)

Used as a status indicator.

LED #6 (Red)

115 VAC power supplied to board.

LED STATUS INDICATORS

LED #4 & #5 (Red) Flashing Alternately = Venter in Pre-purge. (Pre-Purge options 0, 5, 20, 35 seconds)

LED #4 & #5 (Red) Flashing in Unison = Venter in Post-Purge. (Post-Purge options 0, 30 seconds or 1, 2, 4, 8, 16 minutes)

LED #4 (Red) Flashing Continuously*

= Fan Prover opened for more than 10 seconds during burner cycle.

(Venter will run for 10 minutes, attempting to make Fan Prover)

LED #5 (Red) Flashing Intermittently

= With no call for heat, flashes 3 seconds on / 3 seconds off if microcontroller is working properly.

4

LED 1 (AMBER)

LED 2 (BLUE)

LED 3 (GREEN)

LED 4 (RED)

LED 5 (RED)

LED 6 (RED) POWER LED

DRY

24 V

115 V

APPLIANCE

INTERLOCK

RELAY

VENTER

MOTOR

RELAY

A B 1 2 3 4 L N

J1 J2 XL

XN

P1 P2 C GND F

(1 9)

N M MTR

APPLIANCE INTERLOCK

RELAY

1 HP MAX LOAD across

terminals 3 & 4.

VENTER MOTOR RELAY

1 HP MAX LOAD from

terminals L to MTR & M.

XL / XN AUXILIARY DEVICE

POWER TERMINALS

115 VAC - Maximum of 0.15 Amps.

Only connect to Tjernlund auxiliary devices.

SEE WARNING # 1.

MTR & M / N LOAD TERMINALS

FROM VENTER MOTOR RELAY

Used to drive Venter Motor.

1 HP MAX LOAD across terminals MTR & M / N.

L / N - 115 VAC POWER

SUPPLY BLOCK

115 VAC / 50-60 Hz

Circuit protection provided by installer.

SEE WARNING # 3.

APPLIANCE INTERLOCK

TERMINAL BLOCK (A-B, 1-4)

A - B - Dry Contact call. 3 mA @ 5VDC.

SEE WARNING # 1.

1 - 24 or 115 VAC intercepted call.

IMPORTANT: RED voltage jumper must

match intercepted call voltage.

2 - 24V common or 115V Neutral.

3 - Common terminal to appliance relay con-

tacts. IMPORTANT: J1-J2 jumper routes

call voltage at terminal 1 to 3. Remove

J1-J2 jumper if a different voltage source is

provided to terminal 3.

4 - Normally open terminal of appliance relay.

Will be energized from terminal 3 if safety

circuit is “proven”.

J1- J2 CALL

JUMPER

Used when the call signal is

used as the “proven” return

signal to the appliance. See

wiring section for details.

APPLIANCE CALL

VOLTAGE SELECTION

Place RED voltage jumper in

proper location based on

appliance call interlock volt-

age. SEE WARNING # 2.

IMPORTANT

LED STATUS LIGHTS

See “LED Status & Fault

Indicator Section” for details.

DIP SWITCH SETTINGS

Pre-Purge (1-2)

Post-Purge (3-8)

Prover status check (9)

See “Pre / Post Purge &

Prover Status Check Dip

Switch Settings”.

P1 - P2 SAFETY CIRCUIT

TERMINALS

1 mA @ 5VDC.

SEE WARNING # 1.

C, GND, F AUXILIARY DEVICE

COMMUNICATION TERMINALS

2 mA @ 5VDC. For Tjernlund MAC1E or

MAC4E auxiliary devices. SEE WARNING # 1.