Tjernlund GPAK-J,JT,1,1T (Discontinued) 8504013 Rev 3 09/97 User Manual

Page 6

VENT HOOD INSTALLATION

1. Attach the template on page 18 to the interior of the wall the vent hood will be penetrating.

2. Verify that wall penetration will not come in contact with concealed wiring or plumbing. Using a 1/2” drill bit, drill two pilot holes

where noted on the template. The drill bit must be long enough to penetrate to the building exterior.

3. Attach the template to the building exterior aligning the pilot holes on the template with the pilot holes drilled in step 2.

4. Using a reciprocating saw, cut an opening through the building siding, wall board, etc., following the appropriate lines of the template.

5. Slide the Vent Hood through the opening and fasten to exterior wall using provided screws.

6. Once Power Venter is completely installed and secured, apply a bead of exterior rated caulk between Vent Hood flange and exteri-

or of building.

POWER VENTER INSTALLATION

CODE REQUIREMENTS

The Power Venter installation must be done in accordance with the following requirements of the latest Edition of the National Fuel

Gas Code (NFPA #54):

• All portions of the vent system under positive pressure during operation (on the outlet side of Power Venter) shall be designed and

installed so as to prevent leakage of flue or vent gases into the building,

• All appliances must enter the vent system on the inlet side of the Power Venter,

• Provision shall be made to interlock the appliance(s) to prevent the flow of gas to the main burners when the draft system is not

performing so as to satisfy the operating requirements of the equipment for safe performance. See “Electrical Wiring” section of

this manual for details.

INSTALLER NOTES

1. All vent pipe and reducers must be supplied by the installer and are available from your heating wholesaler.

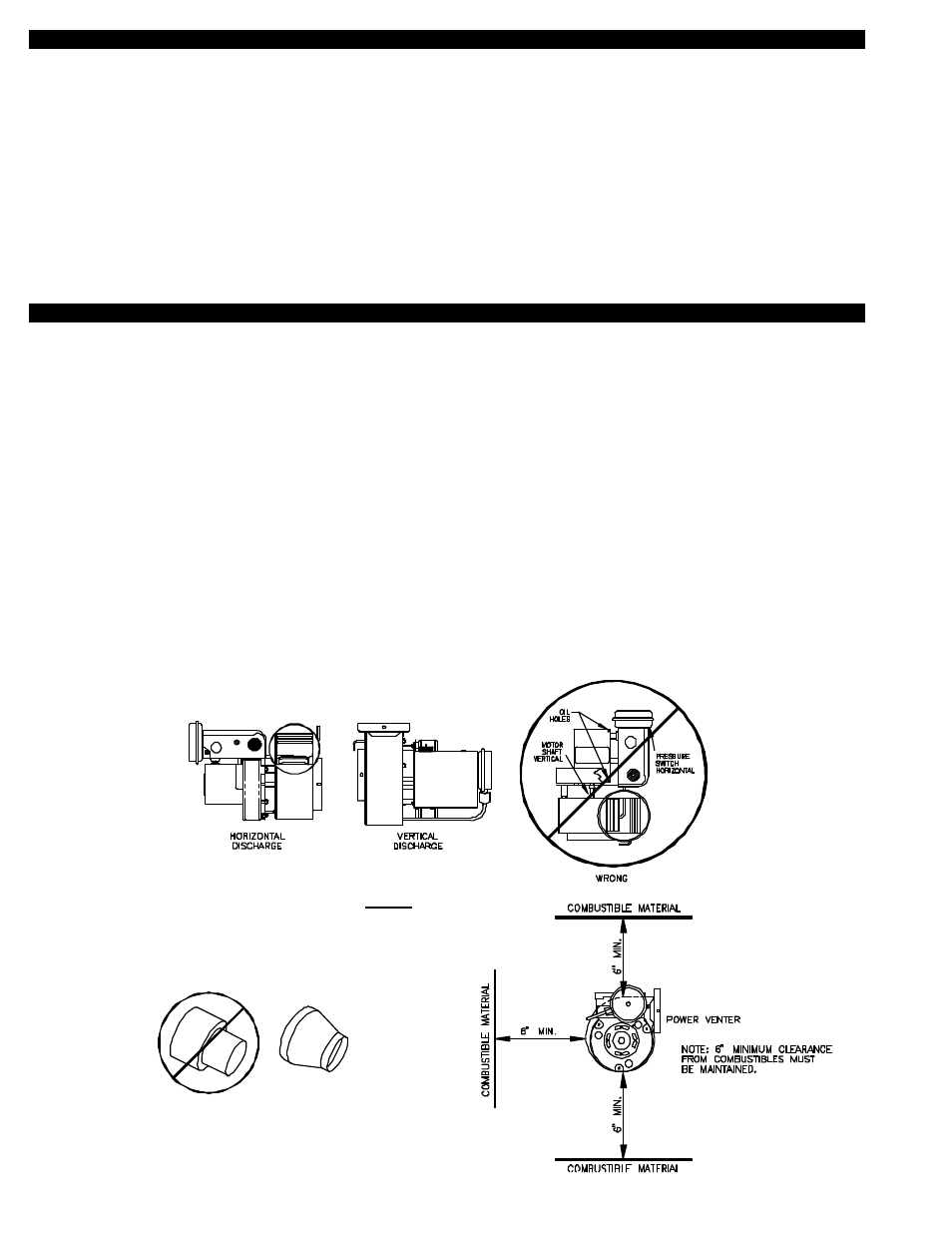

2. To prevent motor bearing wear and to ensure proper Fan Proving Switch operation, the Power Venter must be mounted with shaft

of the motor horizontal, (See Diagram A).

3. If the appliance flue is greater than 4 inch, install a tapered

reducer on the appliance and run 4 inch vent pipe from the

appliance to the Power Venter,(See Diagram B).

4. The Power Venter housing is single wall, a 6 inch clearance

to combustible materials must be maintained,(See Diagram C).

5

DIAGRAM A

DIAGRAM B

DIAGRAM C