Optimum clearance requirement, Alternate construction requirements – Thetford 9100 Series Installation Manual User Manual

Page 6

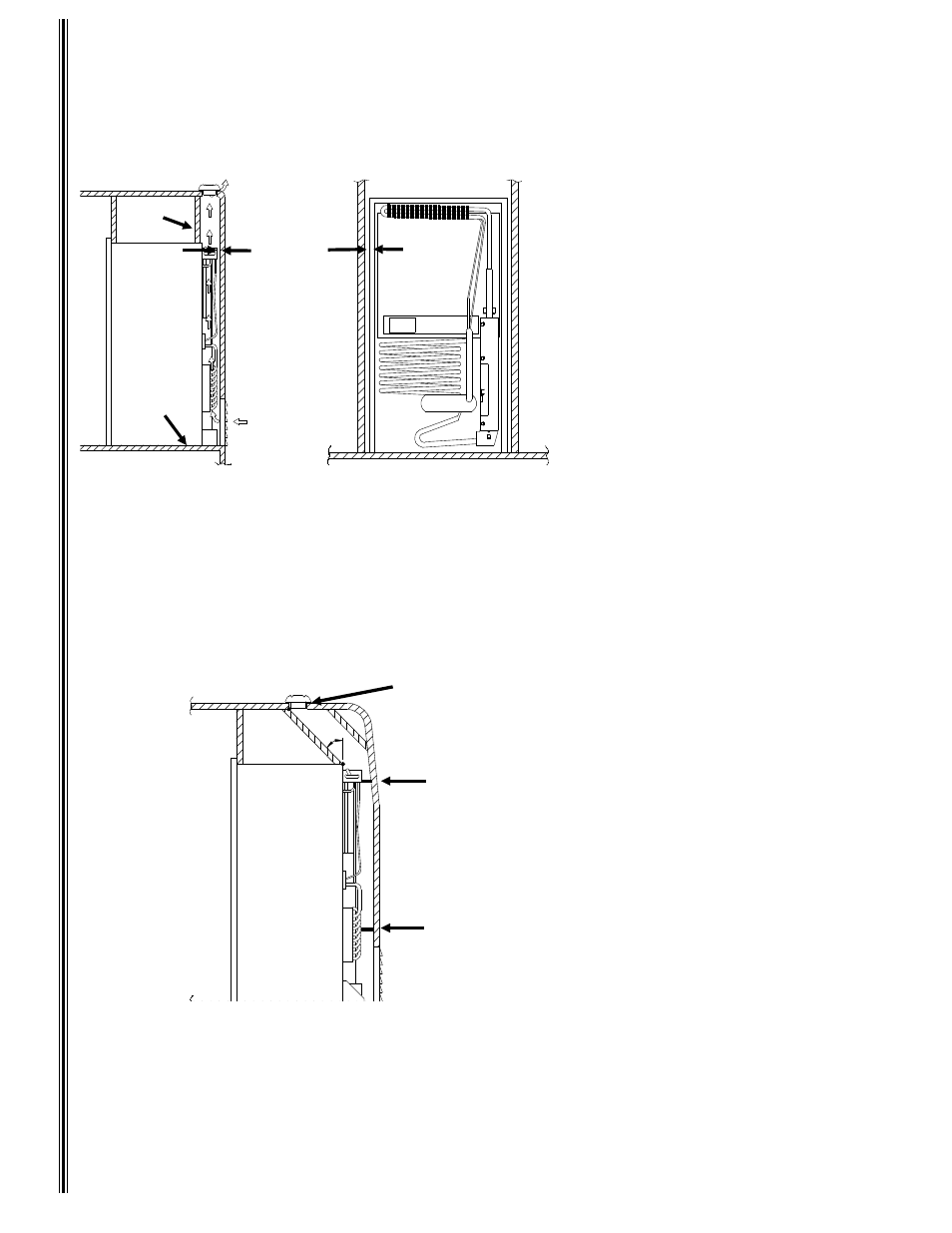

A.G.A. and CGA certification permits installing the refrigerator with zero (0) inches clearance between

the refrigerator and any adjacent walls. This certification does not specify any maximum clearance. However, to

insure adequate air flow across the cooling system, the clearances must be minimized. The recommended

clearances between the refrigerator and any adjacent walls or surfaces are illustrated in Figure 3.

In

stal

latio

n

Requ

iremen

ts

Figure 3

Optimum Clearance

Requirements

•

Minimum clearances between the re-

frigerator and all adjacent walls and

surfaces:

(A) 0 - 1/4 inch at the top of the re

refrigerator

(B) 0 - 1/2 inch at the sides of the

refrigerator

Note: Side clearances in

excess of 1/2 inch must

be either filled with fiber-

glass batting or blocked with

paneling, etc.

(C) O-1 inch at the rear of refrigerator

(D) 0 inches at the bottom of the re-

refrigerator

The combination of the two vents and the clearances

defined provide the necessary air flow through the

creation of a natural draft, or "chimney effect," across

the cooling system.

Air Flow

D

C

B

A

Figure 4

A

Alternate Construction

Requirements

•

Exhaust (upper) vent opening (A) is

inboard in relation to the rear of the

refrigerator

•

Baffles (B) added to top of refrigerator

to assist in directing air flow out the

exhaust vent

•

Angle between baffles (B) and rear top

edge of the refrigerator not to exceed

45 degrees

•

Deflectors (C) added at rear locations

adjacent to the cooling unit condenser

and absorber coils to reduce clear-

ance to 1 inch max.

•

Side clearances are the same as illus-

trated in Figure 3

B

B

C

C

6