Certified vents and dimensions, Certified vent installation requirements – Thetford 9100 Series Installation Manual User Manual

Page 5

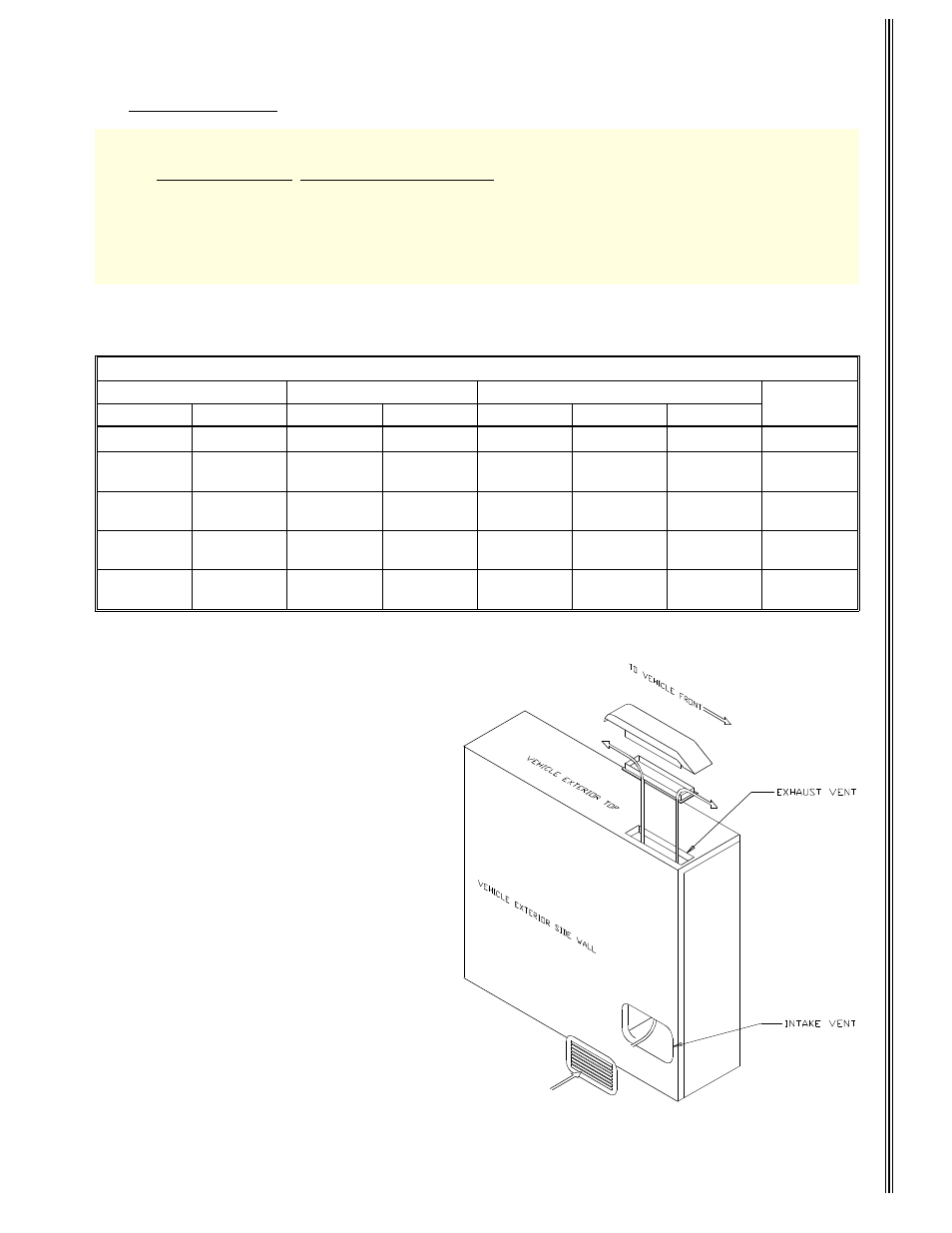

The air passage from the intake vent to the refrigerator coils and from the refrigerator coils through the exhaust

vent must be unobstructed.

Table 1 - Certified Vents and Their Dimensions

Note: Combination of lower intake vent and exhaust vent makes up Norcold Vent kit no. 3.

In

stall

a

ti

on

Req

u

ir

ements

The vents for this refrigerator have been certified by A.G.A. and CGA and must be installed as directed in this

manual without modification. Any deviation or substitution:

1. Can result in carbon monoxide levels in the living space of the vehicle.

2. Will void the agencies’ certifications.

3. Will void the refrigerator warranty.

4. Will effect refrigerator performance.

Cut - Out Dimensions - inches(cm)

Exhaust Vent

Lower Intake Vent

Approved

Models

Part No.

Type

Length

Width

Height

Width

Radius

617778

Plastic

- -

- -

13 3/4 (34.93) 21 1/2 (54.61)

- -

All Models

616010

Square

Corner

- -

- -

13 3/4

(34.93)

21 3/4

(55.25)

- -

All Models

616009

Radius

Corner

- -

- -

13 3/4

(34.93)

21 7/8

(55.56)

3 1/4

(8.26)

All Models

615998

Radius

Corner

- -

- -

13 3/4

(34.93)

21 7/8

(55.56)

3 1/4

(8.26)

All Models

615791

Exhaust

Vent

24

(60.96)

5 1/4

(13.34)

- -

- -

- -

All Models

Figure 2

Certified Vent Installation

Requirements

•

Certified Vent Kit No. 3 installed with-

out modification.

•

Intake (lower) vent installed flush with

or below the surface on which the

refrigerator is mounted

•

Exhaust (upper) vent centered di-

rectly over the condenser of the refrig-

erator’s cooling unit

•

Unobstructed air flow at rear

5