Laser calibration / maintenance – Symtech SCA 1 User Manual

Page 8

H

V

US Low Beam

VOL

.4 Degree Down

(2.096 Inches)

Aim Area

8

•

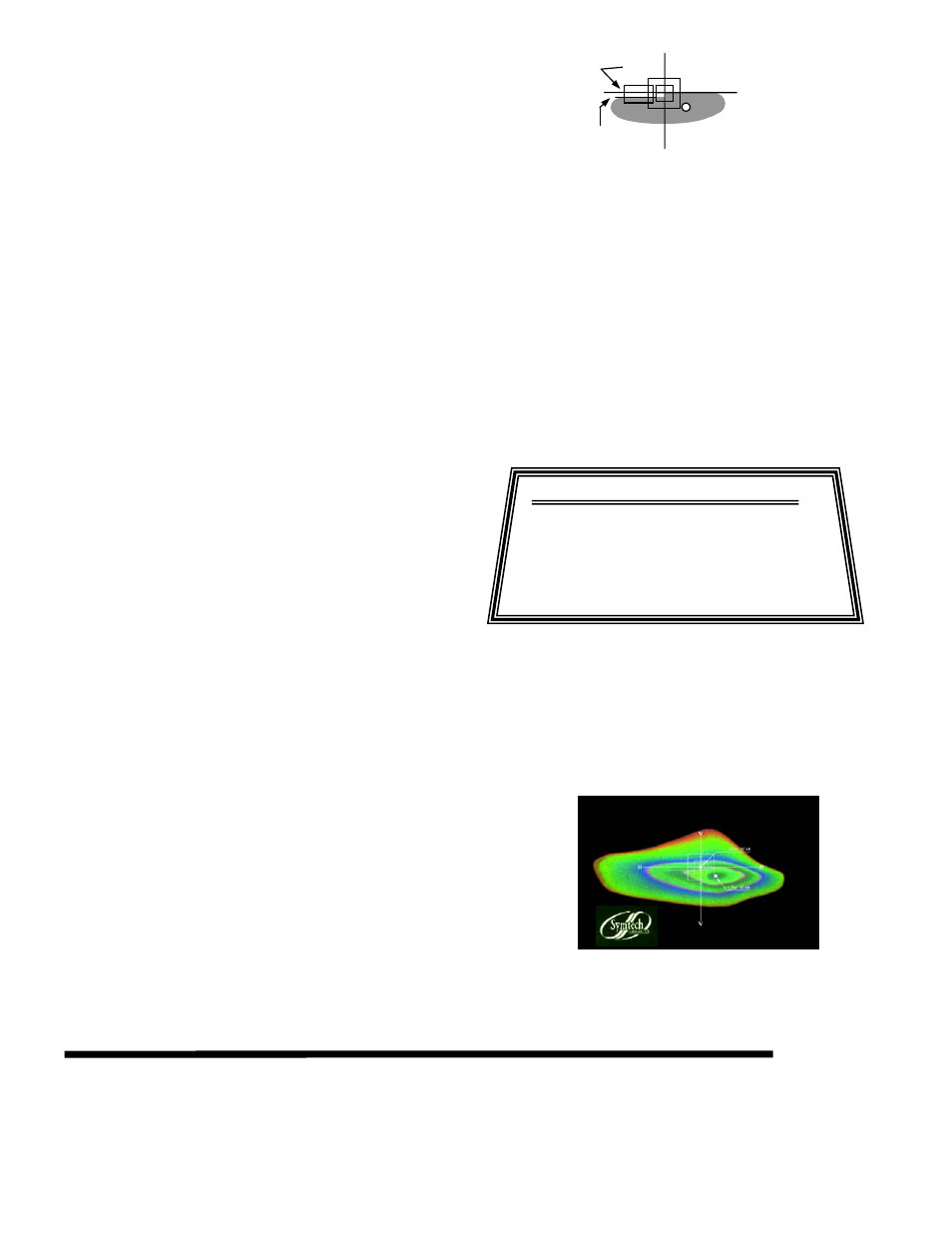

SAE LOW BEAM “

VOL

” (Visual Optical Left):

Low beam lamps manufactured after 1999, some

vehicles. The high intensity area is located in the

lower right hand quadrant and the beam pattern is

aligned by placing the left upper portion of the beam

pattern on the .4 Degree (2.096”) Down Horizontal

axis.

•

HID (High Intensity Discharge / Xenon) Lamps

Some HID / Xenon lamps (bright and bluish in appearance) generate

minimal Infrared emission to activate the ISOColor screen, visual

appearance of pattern on screen may have only one color and possibly

no color. However, a representative visual alignment is achieved by

observing the lamp pattern as depicted on the screen and aligning it to

the appropriate position. In the event of only one, or two colors

appearing on screen, the center of the inner most color represents the

hot spot.

4.4 ALIGNMENT OF HEADLAMP PROCEDURE

1.

Locate SCA 1

ISOColor approximately 12 inches from in

front of the lamp to be aligned. Placement can be 6” to 18”

without jeopardizing alignment.

1. Position “SCA 1” in Front of first

lamp to be Aligned.

2. Adjust Floor Slope to Recorded

Bay Setting.

3. Square SCA 1 to Vehicle by

Looking Trough Sighting Unit.

Headlamp Alignment Procedure

4. Aligning Two Common Points with

Line in Sighting Mirror.

5. Select Lamp Beam Type. While

viewing Lamp Patten, Adjust

Lamp to Pictorial Position

6. Move SCA 1 to Next Lamp and

Repeat Steps 3 Through 5.

2.

Position SCA 1

ISOColor in front of first lamp to be

aligned. Centering of system on headlamp is very

forgiving, as the fresnel lens provides a

± 1.5” widow for

centering.

3.

Align SCA 1

ISOColor to vehicle by sighting through the

sighting unit and rotating optical head until line in sighting

unit intersects the two common points selected.

4.

Headlamps should be switched on to low beam as this is

the primary driving lamp.

a.

In compound lamps, where the Low Beam and

the High Beam are in the same lamp, you only

align one pattern, as by law, the other pattern

must be within 1.5” of perfect alignment.

5.

While viewing aim screen, adjust headlamp to position that

appears as graphic illustration of headlamp pattern selected.

The most inner portion of color is the high intensity zone

and this is what you center over the white dot designated

for the lamp pattern selected.

i. NOTE: Graphics on aiming screen

denote position of lamp position in

inches.

ii. Outer box denotes 8 inches, inner box

denotes 4 inches. Each hash mark

denotes 1 inch increment.

6.

Repeat steps for remaining lamps.

5. LASER CALIBRATION / MAINTENANCE

5.1 FLOOR SLOPE LASER CALIBRATION

“LASER IS CALIBRATED AT THE FACTORY PRIOR TO SHIPMENT”