Symtech SCA 1 User Manual

Page 5

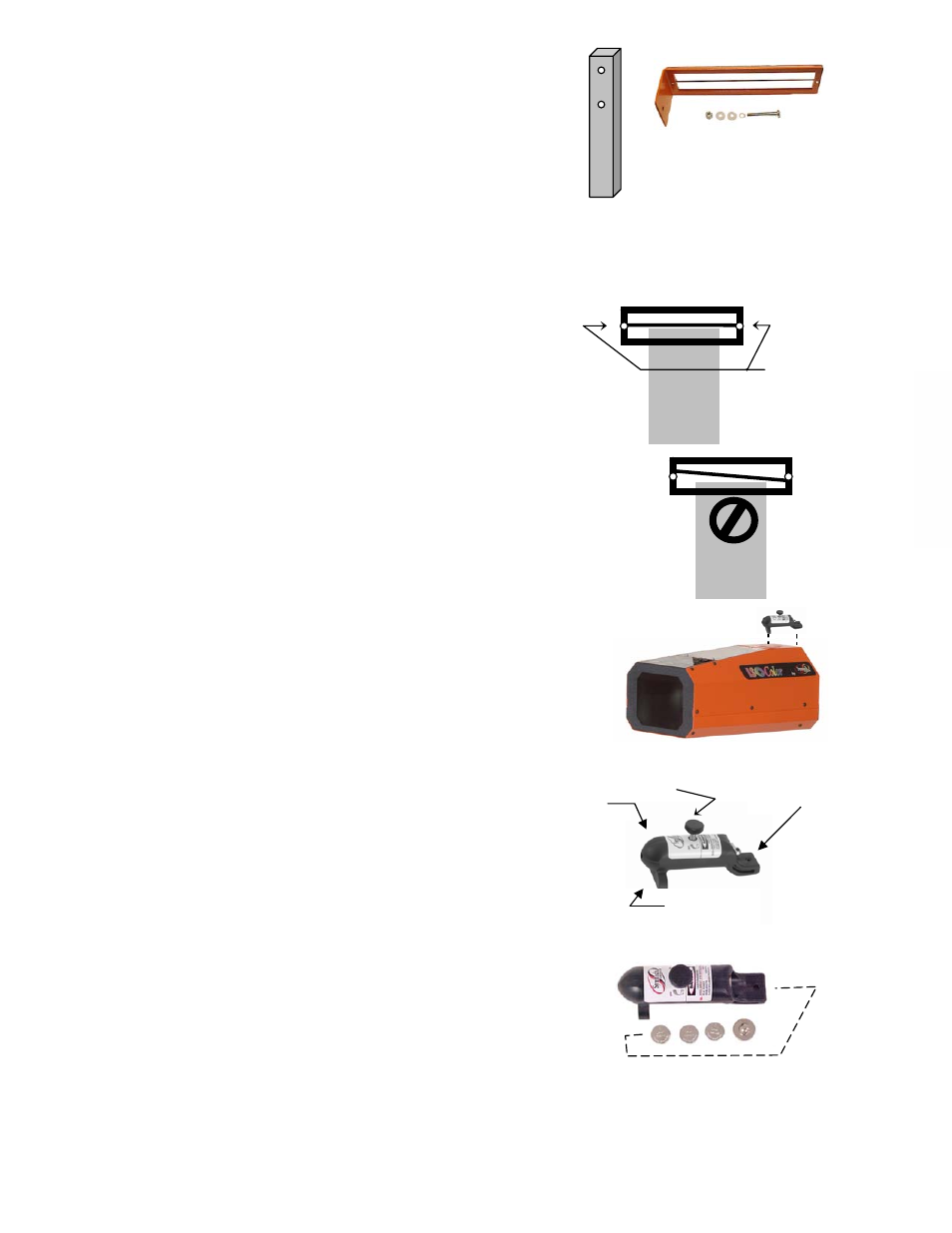

Place a thick nylon bushing on the screw and insert

screw through the holes provided at the top of the

mast, place a thick nylon bushing on screw and self-

locking nut.

Tighten to a tension that allows for movement of

sighting unit, but provides sufficient friction to hold

unit in place when unattended.

NOTE: The mast has two sight unit mounting positions, mount in

the position that is most comfortable for the technician to

sight through

Sighting unit must be calibrated to the optical head prior

to alignment of headlamps.

Optical

Head

IN

Calibration

OUT of

Calibration

Adjustment

Thumb Screws

Optical

Head

2.5 SIGHTING UNIT CALIBRATION

Calibration of sighting unit must be performed prior to alignment of

headlamps.

Raise optical head of SCA 1

ISOColor to the approximate center of

mast.

Turn the sighting unit until you can see the front edge of the optical

head while looking through the sighting unit lens. Line on lens

should line up with the front edge of the optical head.

If line does not line up with the front edge of optical head, loosen

the thumbscrews on the lens and move the lens into alignment.

Tighten thumbscrews.

It is important that periodical checking of calibration of the sighting

unit be performed, to assure proper calibration.

NOTE: When technicians of differing heights are using the SCA 1

ISOColor and the sighting unit is relocated to the optional

mounting position for better viewing, the sight unit must be

checked for calibration and adjustment made accordingly.

2.6 FLOOR SLOPE LASER

The floor slope laser assembly is factory calibrated, DO

NOT turn the level adjustment set screw.

The laser is used for floor slope measurement only. Remove

laser after floor slope measurements have been recorded.

On / Off

Knob

Level Adjuster

Set Screw

Fixture

Placement Pin

ON/OFF

Knob

Remove floor slope laser from packaging and insert front

fixture placement pin into hole on top and at front of the

rear area of the optical head, also there is an indentation

provided for the height adjustment screw to rest within.

Activate the laser by turning ON/OFF knob clockwise

(CAUTION: Excessive turning may damage laser

ON/OFF mechanism) to assure of functionality, turn off

laser. No further adjustment is required.

NOTE: Should calibration of the laser become necessary in

the future, Refer to “LASER CALIBRATION”.

Calibration, Section 5.1, Pg. 9.

Laser Battery Replacement

Unscrew back of laser and replace batteries with three (3), LR 44

button batteries or equivalent. Reverse process for assembly.

After battery replacement, CALIBRATION COULD BE REQUIRED.

5