Origin Live Aurora MKI User Manual

Page 5

5

this exercise will be rewarded. If the bolt is done up too tightly there will be degradation in the performance –

too slack and the sub-chassis may sag obviously to one side ( a little sag is not a problem).

F I T T H E M O T O R P O D

Place the motor pod on the surface where your deck is going to take up residence. Lower the plinth over the

motor pod. The pod should sit roughly centrally in the plate circular cut out for the motor and not touch the

plinth.

F I T T H E T O N E A R M

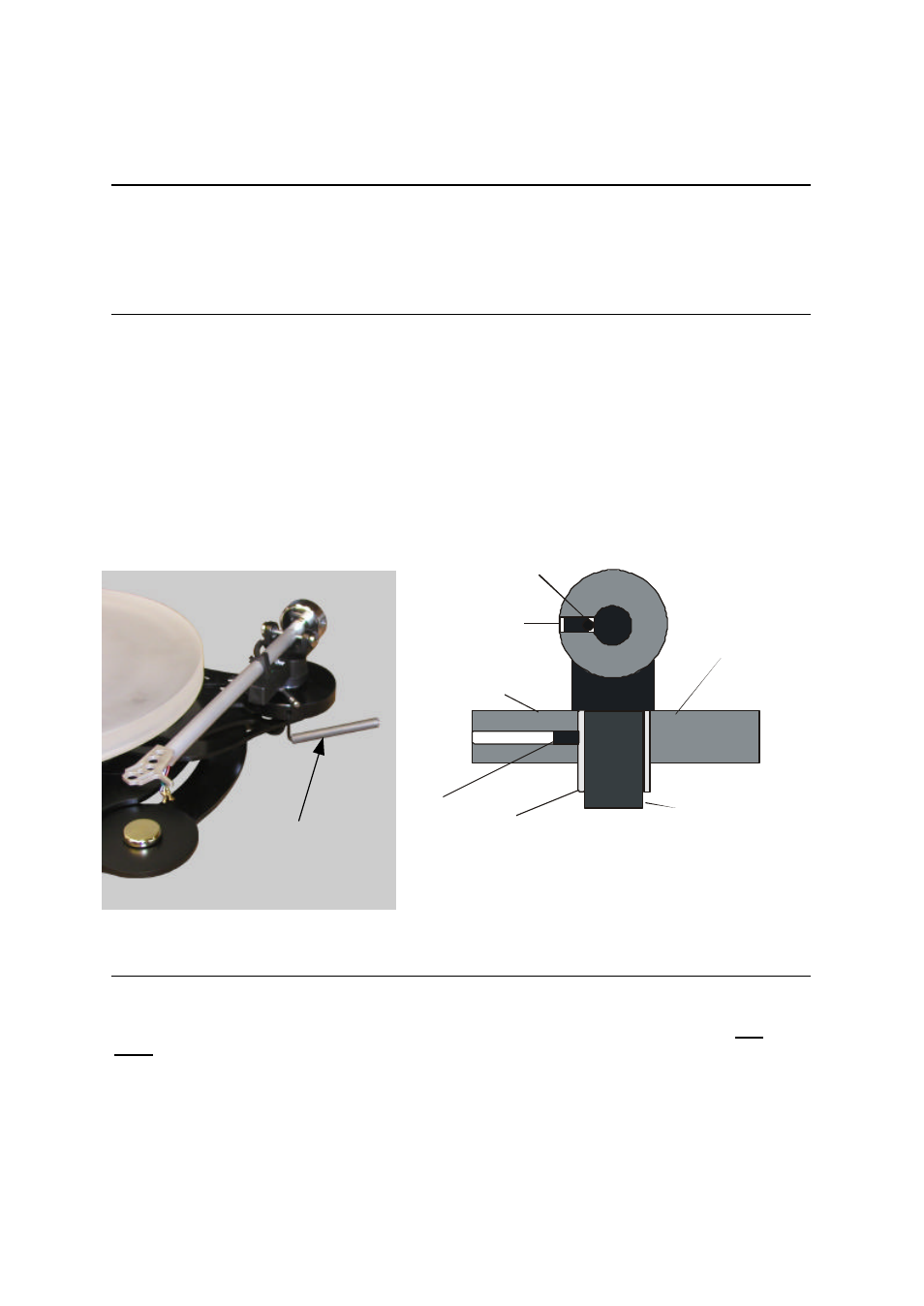

Insert your tonearm into the aluminium sleeve located in the circular arm mounting plate (armboard). You can

set the arm to the correct height using the setscrew located in the arm board as shown in the photo below. This

setscrew clamps the aluminium sleeve onto the arm board. Further to this, when clamped very hard, it deforms

the aluminium sleeve sufficiently onto the threaded arm base to allow it to clamp the arm in position – to

achieve this level of force, you can use the small length of tube supplied. When this is slid over the end of the

Allen key it acts as an extension thus allowing you to exert better leverage as shown in the photo below.

It doesn’t matter whether you slide the aluminium sleeve up and down in the arm board to get the height right

or slide the threaded arm base in the aluminium sleeve. Both methods work fine. Note that you should NOT

clamp the aluminium sleeve hard when there is no arm fitted inside. If you do this, then permanent deformation

will result – the slightest of “nips” is all that is necessary before the arm is fitted. You do not need to fit the

large arm base nut, or any of the washers. To obtain accurate VTA setting you can mark the aluminium sleeve

with pencil lines to keep track of trial positions.

GRUB SCREW POSITION

IS HORIZONTAL

PLINTH OR ARMBOARD

BALL BEARING

ALLEN GRUB SCREW

ALUMINIUM SLEEVE VTA ADJUSTER

THREADED ARM BASE

ARM MOUNTING PLATE

(ARMBOARD)

F I T T H E S U B - P L A T T E R & P L A T T E R

Oil the bearing - with the syringe supplied, run approx 5 drops of oil into the top of the bearing house.

Insert the sub-platter - Wipe the sub-platter spindle surface to ensure that it is absolutely clean and very

gently insert the sub-platter into the bearing house (If the oil does not overflow when the spindle touches the

bottom then try 2 drops at a time till you just achieve overflow - wipe away excess oil) and then place the

platter on top.

NOTE:

The bearing needs a few minutes to “run in” and should run silent when truly vertical and full of oil

- if it

doesn’t do so, there has probably been contamination with dust and you will need to clean it out with a lint free

paper towel or similar wrapped around a thin rod. If you do this, be sure to also wipe the oil off the spindle as

this also may contain microscopic contamination that is not visible.

Metal tube over short

end of 3mm Allen key to

achieve extra leverage

when setting VTA.