Dv-29 micron gauge hook-up – Just Better Deep Vacuum Principles and Applications User Manual

Page 3

Flare

Fitting

45°

Positive

Stop

Specially

Designed

Groove

Locks

O-Ring In

Place

1

2

ing and testing hoses are designed for pressure. Even

with the advanced technology of today's hoses, perme-

ation through the hose compound still exists. When

checking pressure rise, the atmosphere will permeate to

the lower pressure in the hoses and the micron reading

will slowly rise.

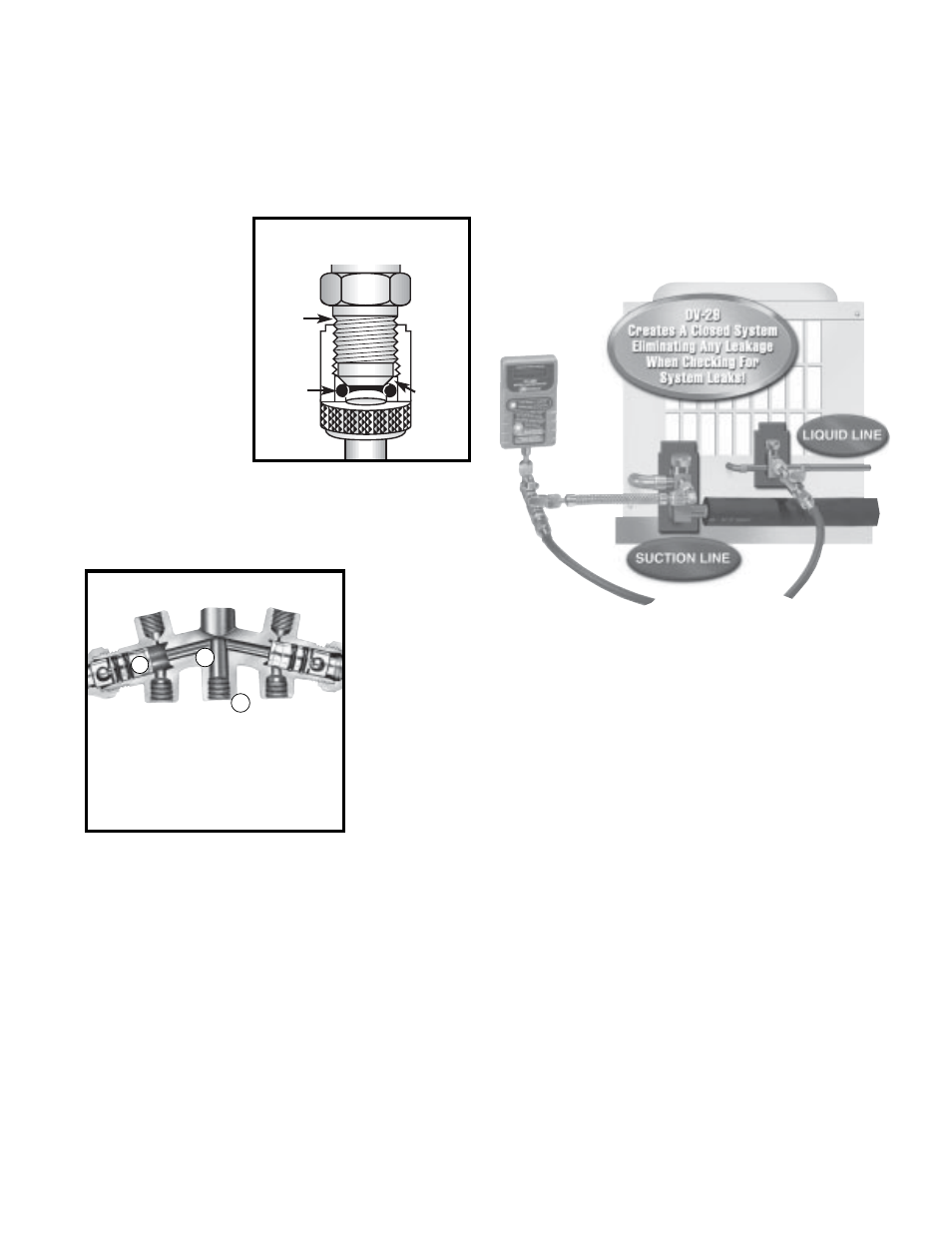

Another source of leakage is the gasket seal in

valve and hose

couplers. This seal is

designed for charging

and will not give a

perfect seal required

in deep vacuum

service. An O-ring

seal coupler, such as

that made by J/B,

forms around irregu-

larities in the flare

fitting. When the

coupler is screwed

down, we get a metal

to metal seat and the

o-ring lays around

the lip of the flare to give a positive seal.

Connecting Lines

We have now covered the simplest hookup to this

point; gauge

manifold with

two 1/4" I.D.

connecting

lines to the

system and a

3/8" connection

to the pump via

line or fittings.

Much has been

said and

written regard-

ing line size,

which would

lead us to

believe the

bigger line we connect, the faster job we’ll do. This

would be true except for the compressor’s service

valves 3/16" orifice. Therefore, we only need to keep the

connecting lines’ I.D. larger than 3/16" This is one of the

limiting time factors in evacuation.

Evacuation should always be done from both the

low and high sides of the system. This could save as

much as 3/4 of the time when evacuating from only one

side. Short connecting lines will save some time;

however, not nearly what some maintain. In relation to

the lengths of tubing in the system, we add very little

restriction via connecting lines.

Before You Start

It is a good idea to attach the micron gauge to the

vacuum pump to make sure the pump pulls down to at

least 50 microns. If it doesn't, your pump is contami-

nated and the oil should be changed. Do not shut-off the

blank-off valve on the pump and expect the gauge to

hold a vacuum as the gauge will fall back to atmo-

sphere. The reason for this is that the sensor is too

close to the pump and the gauge's sensor doesn't have

time to equalize.

Most Leak-Proof Micron Gauge Hook-up

The most leak-proof setup is by using the DV-29.

This unit creates a closed system eliminating any

leakage under deep vacuum.

J/B Piston Type Manifolds

Deep Vacuum

O-Ring Coupler Cut-Away

1. Stem seats retract completely

from flow path.

2. Double size flow path through-

out length of center port.

3. Convert to 3/8" port with 3/8mf x

1/8mp

3

The DV-29 test unit (see illustration) eliminates

other problems when attaching the micron gauge into

the system. If the micron gauge is attached directly to

the vacuum pump or with 3' dedicated hose, we will get

a lower reading as the gauge is sensing what the pump

is doing and not what the pump is doing to the system.

General Micron Gauge Hook-up

When designing your hook-up system, choose from

the following hoses, valve and coupler designed for

leak-proof service in a deep vacuum environment.

1. D10436 or D10427 1/4" Metal Hose and D10636 or

D10660 3/8" Metal Hose with o-ring couplers. Your

hook-up through manifold, pump and if desired, to the

micron gauge.

2. A34000 Quick Coupler Tee w/o-ring seal. Since the

most accurate reading is obtained at the

compressor's high or low side, use to tee-off the

gauge.

3. D10162 ball valve with O-ring quick coupler to valve

off gauge before charging. Depending on the gauge,

it should be remembered that the electronic gauge's

sensors will not take pressure beyond 1 to 100

pounds. Depending on hook-up, use with metal hose

or A34000 coupler.

1. Works with all micron gauges

2. No additional equipment needed

3. Leak-proof components

DV-29 Micron Gauge Hook-Up

Hoses to Manifold