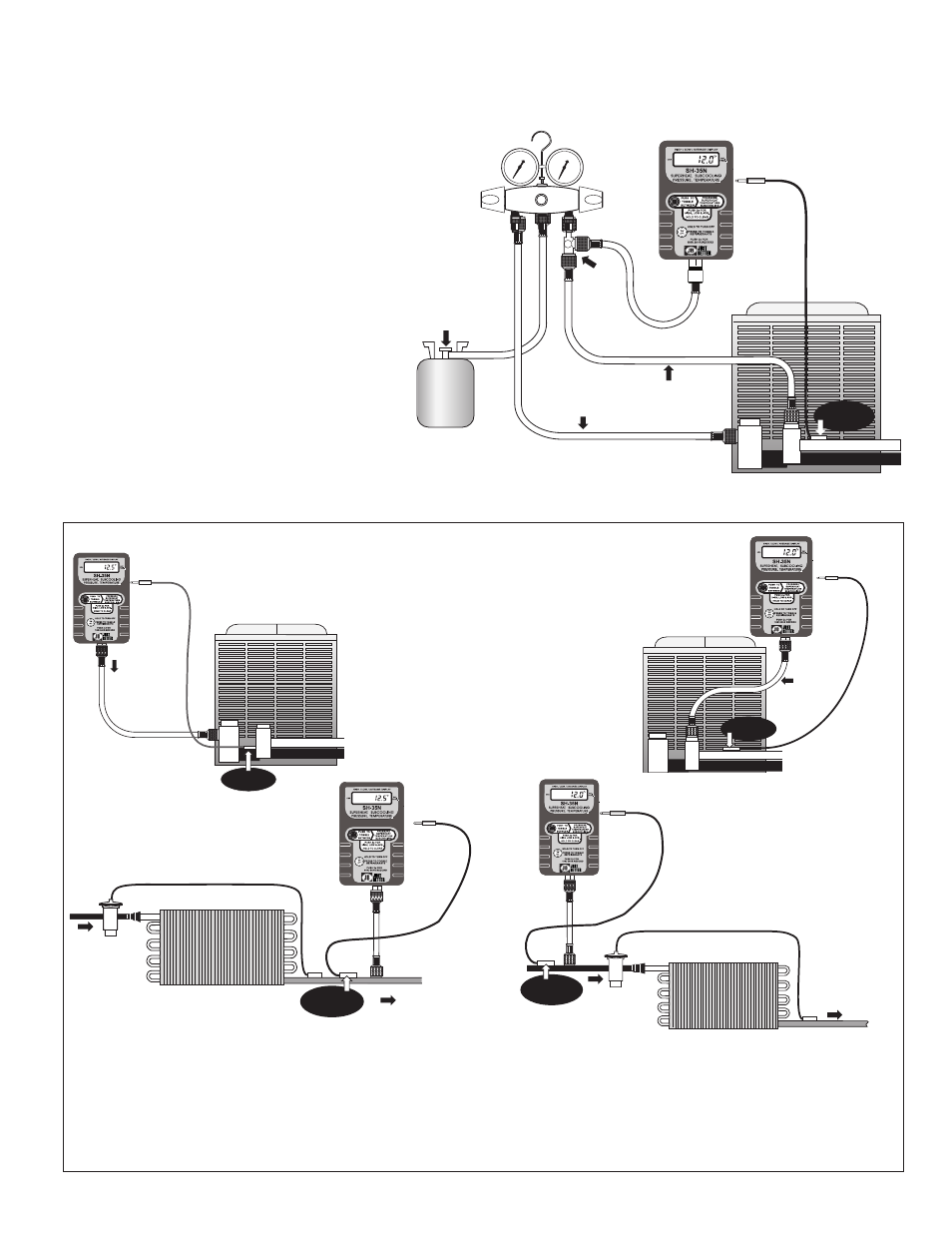

Charging by the subcooling method, Testing for charge, Superheat test – Just Better SH-35N Superheat Subcooling User Manual

Page 3: Subcooling test, Superheat, Systems with txv and no receiver

A34000

1/4” SAE TEE

W/SWIVEL

COUPLER

TEMPERATURE

SENSOR

SUCTION LINE

LIQUID LINE

CONDENSING

UNIT

REFRIGERAN T

TANK

QC RESTRICTOR

FITTING

TO

LIQUID LINE

SERVICE VALVE

TEMPERATURE

SENSO R

SUPERHEAT

SUBCOOL

SUCTION LINE

LIQUID LINE

TEMPERATURE

SENSOR

CONDENSING UNI T

TEMPERATURE

SENSOR

SUPERHEAT

SUBCOOL

SUCTION LINE

LIQUID

LINE

TEMPERATURE

SENSOR

EXPANSION

VALVE

TEMPERATURE

SENSOR

SUPERHEAT

SUBCOOL

1. Connect the gauge to the A34000 tee fitting on

the high (liquid) side of the manifold as shown.

2. Install the Temperature Sensor on the liquid line

next to the liquid service valve and plug into

gauge.

3. For system refrigerants other than R-22, scroll

to the matching Refrigerant.

4. Toggle the gauge display to show

SUBCOOLING.

5. Very slowly add or remove refrigerant until the

gauge displays the required Subcooling value.

SUPERHEAT TEST

SUCTION LINE

LIQUID LINE

TEMPERATURE

SENSOR

CONDENSING UNIT

TEMPERATURE

SENSO R

SUPERHEAT

SUPERHEAT

SUBCOOLING TEST

1. Turn on the gauge.

2. For refrigerants other than R-22, scroll to

Refrigerant.

EVAPORATOR

SUCTION LINE

LIQUID

LINE

TEMPERATURE

SENSOR

TEMPERATURE

SENSO R

SUPERHEAT

SUPERHEAT

2. Plug in the Temperature Sensor and mount the

sensor as shown.

3. Toggle the display to show Superheat or

Subcooling.

CHARGING

BY THE SUBCOOLING METHOD

APPLICATIONS

Refrigeration Systems

High Efficiency Residential

Large Commercial A/C Rooftop

Packages Up To And Over 100 Tons

Average Subcooling Value is 10°–12°.

Contact manufacturer or wholesaler for specific temperatures.

Systems With TXV And No Receiver

TO SUCTION

SERVICE VALVE

TO SUCTION

SERVICE VALVE

EXPANSION

VALVE

EVAPORATOR

TO LIQUID

SERVICE

VALVE

TESTING FOR CHARGE

EVAPORATOR

SUCTION LINE

LIQUID

LINE

TEMPERATURE

SENSOR

TEMPERATURE

SENSO R

SUPERHEAT

SUPERHEAT

MULTI KEY

EXPANSION

VALVE