Just Better Cleaning Vacuum Sensor User Manual

Cleaning vacuum sensor, Instructions

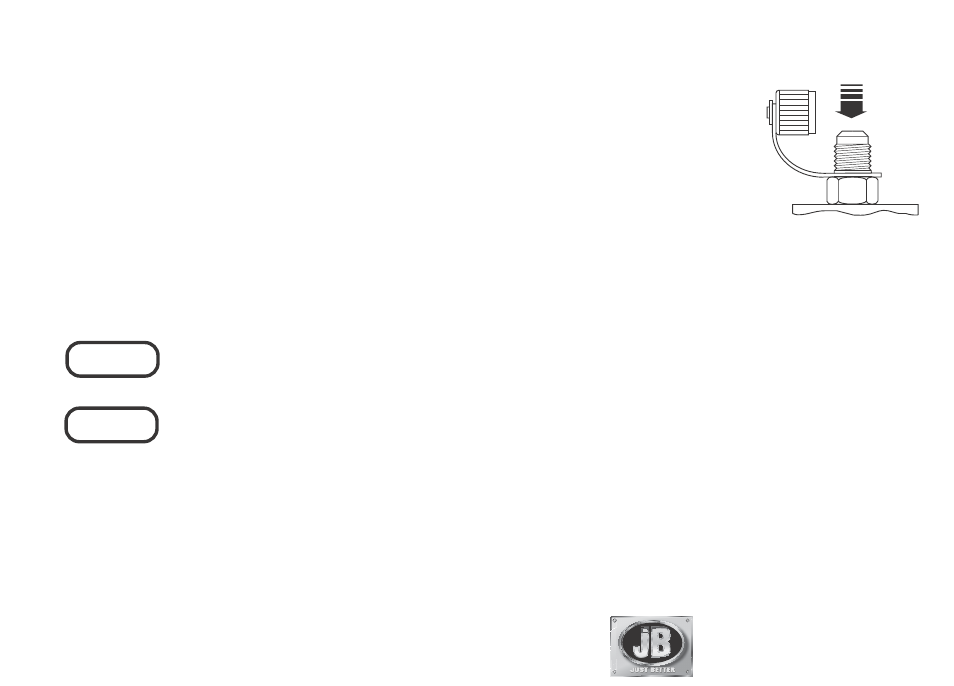

CLEANING VACUUM SENSOR

Remove protective cap. Fill vacuum hose

connection fitting half full with alcohol.

Replace cap. Gently shake the gauge to

allow the alcohol to rinse the inside of the

sensor.

Remove cap and pour out the alcohol.

Turn gauge upside down and allow the

vacuum sensor to dry for 20-30 minutes

before using gauge or replacing cap.

WARRANTY

DV-20 is warrantied for 12 months after

manufacture date. The warranty covers a 6

month over-the-counter return with the

balance covering repair only. For repair,

return the complete unit to your local

wholesaler. In warranty items must have a

copy of the invoice included.

INSTRUCTIONS

1. Connect a NEW dedicated charging hose or metal hose to the micron

gauge. All pre-used hoses contain oil and this will contaminate the sensor.

2. With hose attached to gauge, connect a D10162 shut-off valve on the

opposite end. This is a safety precaution to protect the gauge sensor from

pressures exceeding 300 psi.

3. It is recommended to connect the micron gauge hose directly to either the

high or low side of system for a more accurate reading. However for

convenience, the micron gauge may be connected directly to the vacuum

pump or charging manifold with hose no shorter than 3 feet.

4. Push square button to turn gauge on. If unit does not display any

characters, check to be sure batteries are correctly installed. The start-up

character display will read in the following order.

Sensor calibrates automatically at start-up and

monitors vacuum level every 5 seconds.

Displayed until system has gone down below 9,999

microns at which time visual display will begin.

5. The micron gauge power saver feature automatically turns the gauge off

after 10 minutes. To continue, repress the start button; J:B will be

displayed followed by the current reading.

6. To check for a leak using the vacuum pump blankoff valve, a metal hose/

O-ring coupler or copper tubing must be used; standard hoses permeate

and will not hold a vacuum. The reading will increase naturally due to

equalization; a minimum of 5 minutes is normal at which time the reading

should hold. Continual increase may indicate a leak within the system.

MICRONS

J:B

MICRONS

1

OIL IN THE SENSOR

WILL CAUSE

ERRATIC READING

DO NOT USE

Q-TIP'S TO CLEAN

SENSOR.

JB INDUSTRIES

630.851.9444

Printed in USA

© 2007 J/B Industries Inc.

Form 10751-306