Step 10, Step 11, Step 12 – Craftsman 351.21833 User Manual

Page 6

STEP 10

ATTACH EXTENSION TABLES

Tools Required: 13mm Open End Wrench and Straight Edge

Hardware Required: Six M10 x 25 hex head bolts, six M10

lock washers and six M10 flat washers (Hardware bag #1).

• Assemble extension table to the table using hex head

bolts, lock washers and flat washers.

• Hand tighten only. Do not tighten completely until tables

are level. Use a straightedge to level tables.

• Repeat above procedure for the other extension table.

• Use a straight edge to check level and flatness between

main and extension tables.

• After tables are adjusted level and flat, secure the exten-

sion tables by tightening the hex nuts completely.

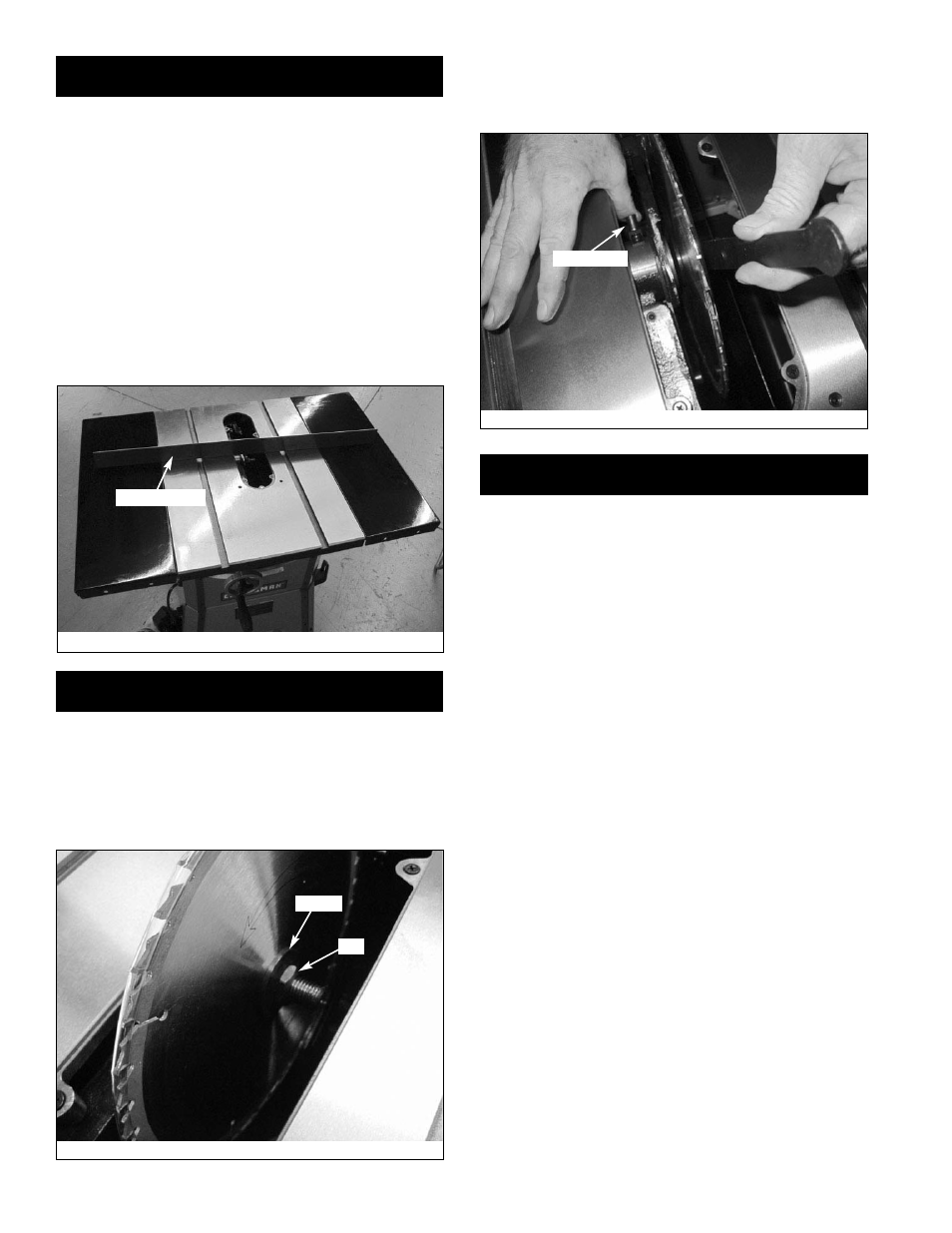

STEP 11

INSTALL BLADE

Tools Required: 13mm Open end Wrench

• Loosen knob on right side of cabinet.

• Remove blade and wrench. Replace knob.

• Depress arbor lock and use wrench to loosen flange nut.

Remove flange and nut from arbor.

• Place blade on arbor. Make sure arrow on blade and teeth

point towards front of saw.

• Replace flange and nut on arbor and securely snug blade

in position.

STEP 12

CHECK TABLE ALIGNMENT

• Saws are shipped from the factory with the table adjusted

so the miter gauge slots are parallel to the saw blade.

However, in order to obtain the best results from the saw, it

is suggested this adjustment be checked before operating.

• A simple method of checking alignment is as follows: Bolt

or clamp a dowel rod or similar object to miter gauge (a

combination square can be substituted). Pick out a tooth

on front of blade and set the dowel to it so it is just touch-

ing. Move same tooth to back of blade.

• Gauge this tooth with the dowel rod. If the tooth is in the

same position, relative to the miter gauge slot, the table is

parallel with the blade. In short, the miter gauge slots must

be parallel with the blade. This means that when measur-

ing distance between blade and slot at the front and rear

of the blade, the distances will be equal (see Figure 20).

NOTE: Be positive to measure the distance or make the test

on the same tooth of the saw blade in both front and rear

positions.

• If an adjustment is necessary, proceed as follows: (Refer

to Figure 13 in operator’s manual). Loosen the hex head

bolts and lock washers (Nos. 36, 37 and 38) of the trun-

nion. Shift trunnion until a position is found where the saw

blade is parallel to the miter gauge slots.

NOTE: Saw blade should also be centered within its table

insert opening.

6

Figure 17

Flange

Straight Edge

Nut

Figure 18

Arbor Lock

Figure 19