Starting the engine, Fuel for the evolution gas engine – Evolution Engines EVOE116GX2 User Manual

Page 5

Starting the engine

The new Evolution Engine carburetor comes adjusted to a

basic setting. This setting should be maintained during the

initial break-in runs.

Before you first start the engine, make sure that the spark

plug is screwed in and tightened and that the plug socket

is fitted in place and fastened down properly. Fix the ignition

sensor in the proper position above the magnet with the

screws enclosed. Follow the directions in the Ignition System

addendum on page 8 to mount the ignition module in your model.

Important: Never turn the engine over with the ignition

turned on unless the spark plug is inserted in the plug socket.

This could lead to ignition damage.

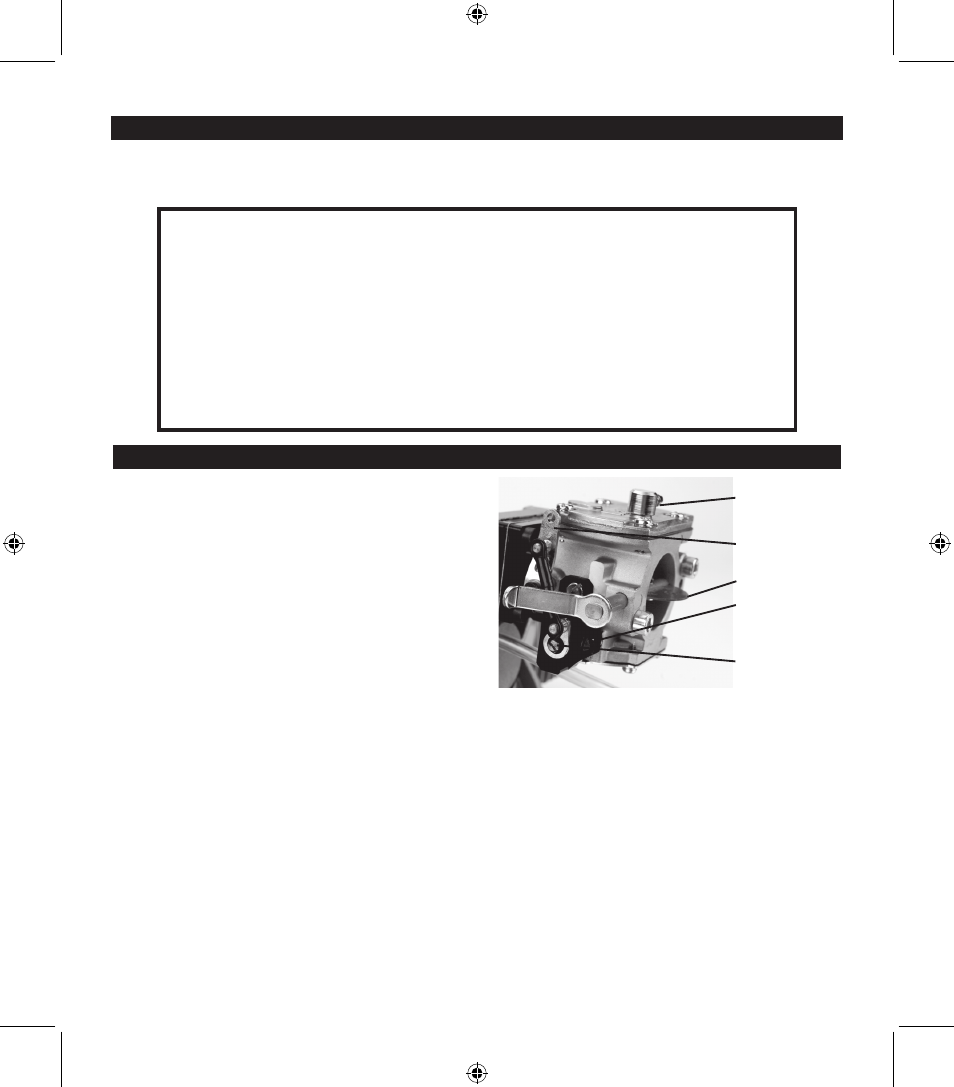

carburetor Adjustments

Adjust needle (L) for low rpm range 3/4 turn open

Adjust needle (H) for high rpm 1 turn open

NOTE: The Low Speed adjustment is to the left of the high speed needle.

Basic setting: throttle closed

4

Fuel for the evolution gas engine

The Evolution

®

Gas engine has been designed to run on a mixture of high-quality unleaded gasoline and synthetic oil intended for racing

2-stroke gasoline engines. For the run-in period of the new engine, mix the fuel in a ratio of 30 parts gasoline to 1 part lubricant. After

run-in, use a ratio of 40 parts gasoline to 1 part lubricant.

Ignition System Warning

It has come to our attention that some users are not aware that

when using the GT2/GX2 electronic ignition, it fires the spark

plugs for 1 second to check the condition of the battery prior to

starting the engine. If the engine is in the compression position

(i.e., the piston is above the exhaust port in either the up OR

down part of the stroke), any compressed fumes may ignite,

causing the propeller to turn and possibly the engine to start

unintentionally.

To prevent this with the Evolution Gasoline GT2/GX2 Ignition

System, the Ignition Power Switch must be turned off; check to

see that the piston is in the bottom dead center (BDC) position.

Bottom Dead Center can be found by rotating the propeller

through the compression stroke. As you rotate the propeller you

will feel it tighten, then suddenly loosen. Once the turn becomes

very easy you have completed the compression stroke and are at

BDC. Once you are sure the piston is in this position, you may

turn on the ignition power switch and operate the system safely.

As always, it is important to use extreme care when near

or with engines, fuel and propellers. Please use caution when

working with these components. If you have any questions or

concerns, please contact our Product Support team at 1-877-

504-0233 or [email protected].

1) When you are ready to start your engine, make sure that the ignition is switched off, the choke valve is closed and the throttle valve

is partly open. Confirm that fuel is filling the fuel line to the carburetor, then switch the ignition to the on position. Flip the propeller

smartly until the engine fires. With the choke in the closed position, the engine will fire then quit.

2) Open the choke valve and set the throttle at a slightly high idle position. Be sure to have a helper hold the model securely. Give

the propeller a few quick flips. When the engine starts, allow it to idle for 30 to 45 seconds in order for it to warm up to operating

temperature. At this point, you can proceed to test the carburetor settings before flying your model. See the following section regarding

carburetor adjustment.

Adjusting Needle L

Adjusting Needle H

Choke

Pressure Inlet

Throttle Arm

9477.3_EVO116GX2_Manual.indd 4

4/20/07 3:13:52 PM