Maintenance – Electric Eel RF User Manual

Page 9

Model RF Manual (082610)_2-ColorREV.doc

Page

9 of 16

8. If tool becomes hung up in the

obstruction, move control lever

to the REVERSE position to back

out too. (See Figure #5)

NOTE: It is not necessary to use

the FOR/REV toggle switch on the

motor at this time.

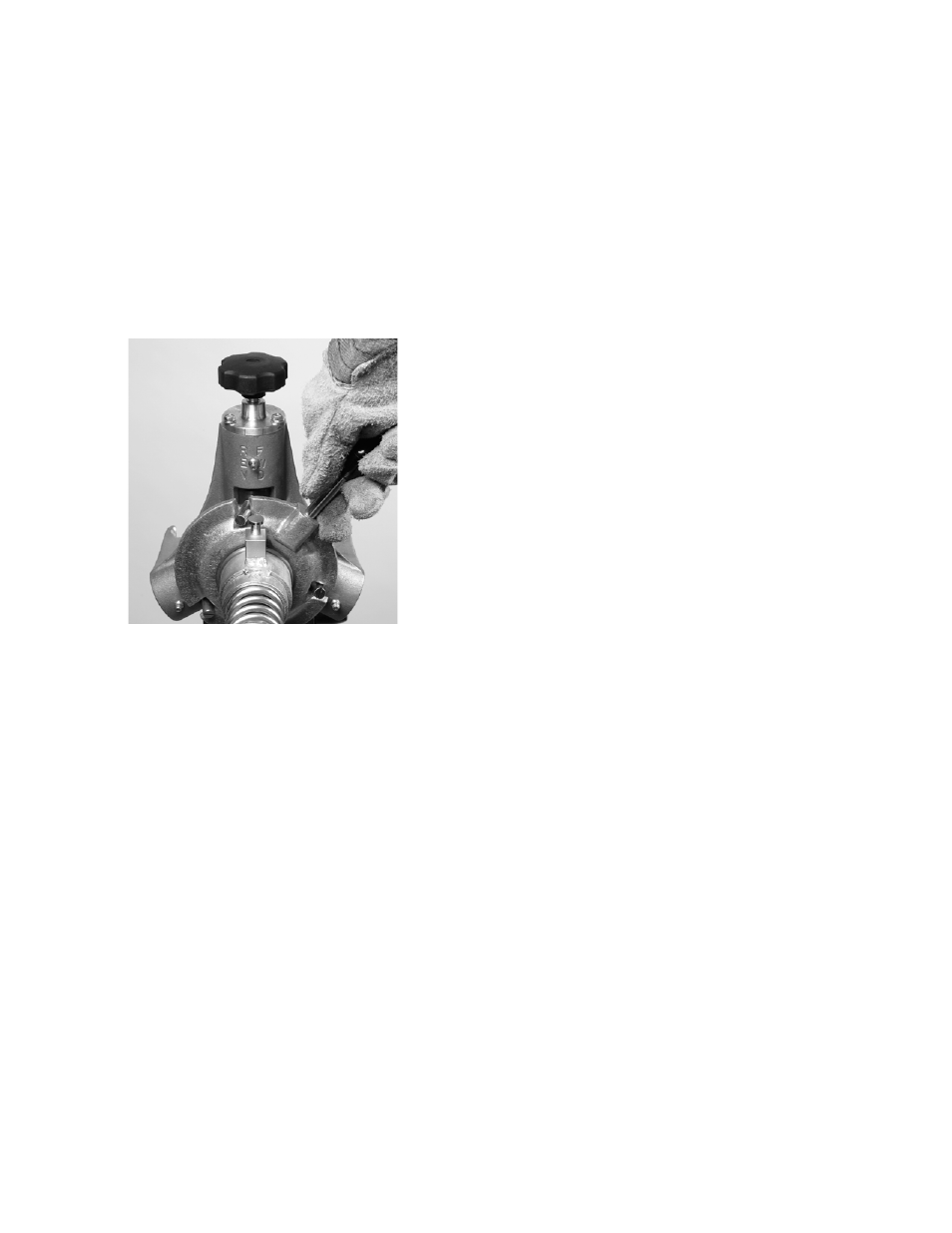

Figure 5

9. After tool has been removed

from obstruction, move control

lever back to the FORWARD

position and continue to work

through

obstruction.

10. To retrieve cable from line,

move control lever to the

REVERSE position (while

continuing to operate cage in

forward rotation) and cable will

back out of line and feed into

cage.

NOTE: It is recommended to use a

continuous flush of water to clean

tool, cable and sewer line as cable is

retrieved.

11. When tool is close to cleanout

opening, return Control Lever to

NEUTRAL position, place switch

in OFF position, release foot

actuator and allow machine to

come to a complete stop.

DISCONNECT POWER CORD.

12. Pull remaining cable and tool

from drain line and hand-feed

cable back into machine.

MAIN SEWER OR SEPTIC

TANK OVERUN

Operator should determine the

approximate distance from cleanout

opening to the main sewer or septic

tank. Overrunning cable into these

areas can cause cables to twist or

knot-up preventing their retrieval.

MAINTENANCE

Maintenance on the RF machine should

be minimal for the life expectancy of

the machine. The cable cage is

equipped with bearings which do not

need to be lubricated, but an

occasional lubrication with oil to the

machine shaft will help in removal of

cable cage and will not harm the

bearings.

A light coating of oil applied to the

cable before storing will help prevent

rusting and premature failure.

Greasing all three (3) grease Zerks

(fittings) on feeder before each use is

recommended. Disassemble and clean

complete feeder twice yearly.