Dynojet 224: Eddy Current Brake User Manual

Page 41

TO R Q U E M O D U L E I N S T A L L A T I O N

Load Cell Calibration

Version 3

Model 224 Above Ground Eddy Current Brake Installation and User Guide

2-11

Once the Zero Calibration is complete, the Calibration Mass window will appear.

5

Enter the Torque Module calibration value. Refer to Figure 2-13.

Note: You must perform this step the first time you calibrate the load cell.

Or

If you are only performing a Zero Calibration, click Finish.

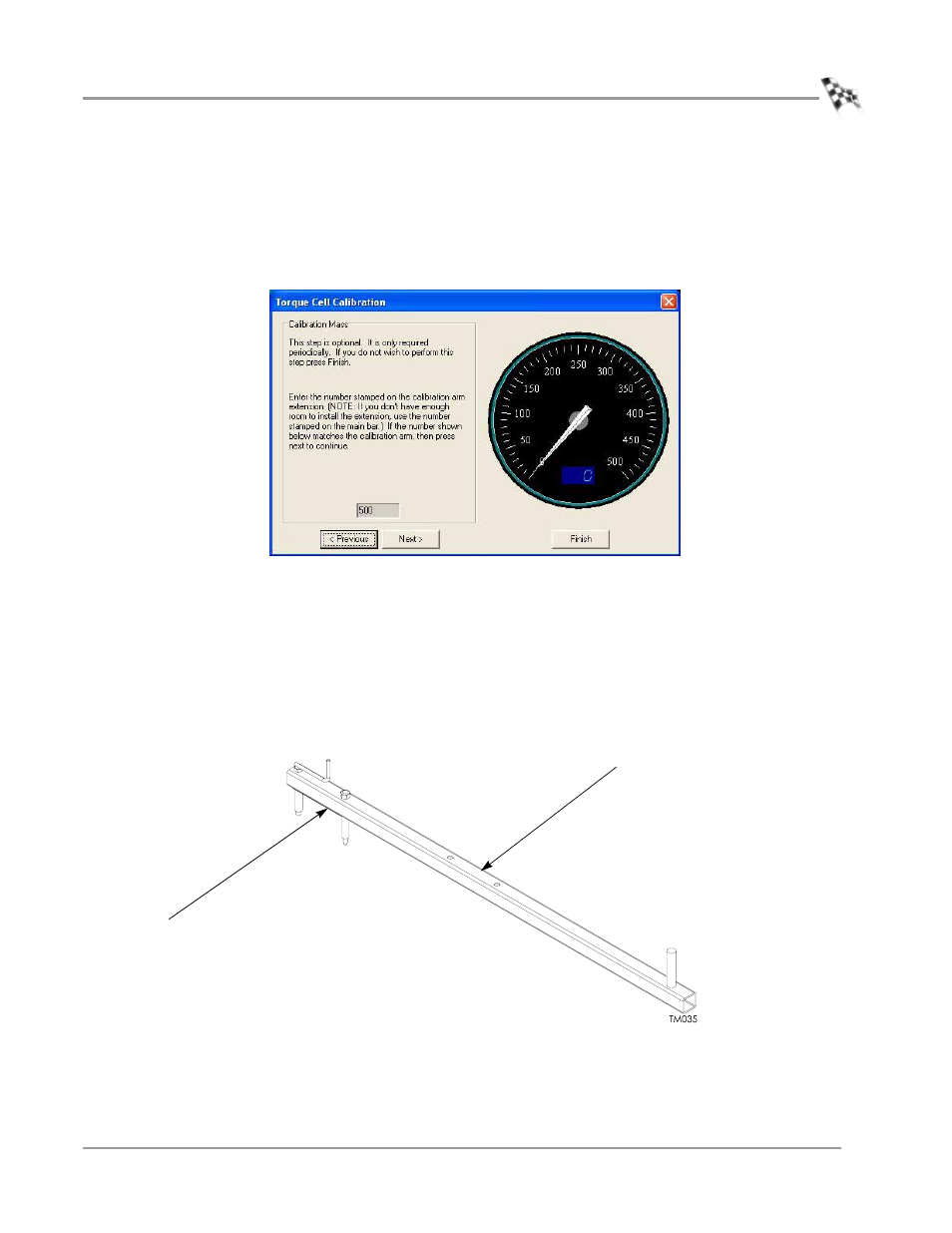

Figure 2-12: Calibration Mass Window

Enter the calibration number stamped near the bolt pattern at the end of the

calibration arm. If you do not have enough room to use the bolt pattern closest to

the end of the calibration arm, use the number stamped near the bolt pattern in

the center of the arm.

Note: Dynojet recommends you secure the calibration arm using the bolt pattern

closest to the end of the arm unless space constraints in your dyno room do not

allow you to.

Figure 2-13: Calibration Arm Number

bolt pattern closest to

the end of the

calibration arm

bolt pattern near the

center of the

calibration arm

- 150: Kart and ATV Dynamometers (44 pages)

- 150: Dyno Drum Cover for Kart and ATV Dyno Motorcycle Option (3 pages)

- 150: WinPEP 7 (170 pages)

- 168: Eddy Current Brake (27 pages)

- 200: Eddy Current Brake (45 pages)

- 200: Replacing the Starter Ring Gear (7 pages)

- 200: Safety Switch (3 pages)

- 200: DynoWare EX+ Upgrade Installation Guide for Motorcycle Dynos (20 pages)

- 200: Throttle Stop (3 pages)

- 200: Eddy Current Brake Driveline Upgrade (17 pages)

- 200i: High Pressure Blower (20 pages)

- 200: Installation Guide (73 pages)

- 200i: Pit Installation Guide (154 pages)

- 200i: Pre-Installation Guide (52 pages)

- 200i: Installation Guide (184 pages)

- 200i: Air Brake and EEC Kit (40 pages)

- 200i: Dynamometer Wiring Schematic (2 pages)

- 200i: Folding Ramp (15 pages)

- 200i: Control Panel Interface Upgrade (S/N 201xxxx) (31 pages)

- 200i: Control Panel Interface Upgrade (S/N 202xxxx) (29 pages)

- 200i: Motorcycle Exhaust Extraction System Drawings (18 pages)

- 200iP: Pit Installation Guide (148 pages)

- 200iPX: Installation Guide (163 pages)

- 200iPX: Installation Guide (52 pages)

- 200ix: Pit Installation Guide (163 pages)

- 200ix: Extended Carriage and Trike Adapter Assembly (15 pages)

- 200iX: Upgrade Installation Guide (56 pages)

- 200ix: Extended Carriage with Trike Adapter Assembly (13 pages)

- 224: CE Package (17 pages)

- 224: Maintenance Guide (35 pages)

- 224: Installation Guide (78 pages)

- 224/4WD: Installation Guide (77 pages)

- 224: Pit Installation Guide (56 pages)

- 224x: Above Ground Four Post Lift Dimensions (1 page)

- 224x: Pre-Installation Guide (63 pages)

- 224x: 4WD Dyno Air and Wiring Schematic (2 pages)

- 224: Pit Eddy Current Brake (69 pages)

- 224xLC2: Quickstart guide for DWRT (2 pages)

- 248: Pit Installation Guide (74 pages)

- 248: Installation Guide (58 pages)

- 248: DynoTRAC User Guide with Variable Brake (14 pages)

- 248: DynoWare EX+ Upgrade (22 pages)

- 248: Optical RPM Sensor (22 pages)

- 248: Proportional Air Brake (21 pages)