Installation - flush mount, Installation - bracket mount (sold-separately), Wiring 2 kits together – Code 3 HB4PAK User Manual

Page 2

2

Installation & Mounting

1. Select location to mount LED CONTROLLER.

2. Use double-sided tape (or similar) and mount on clean surface.

3. Route RED and BLACK wires to vehicle power source.

4. Select desired Flash Pattern using YELLOW wire.

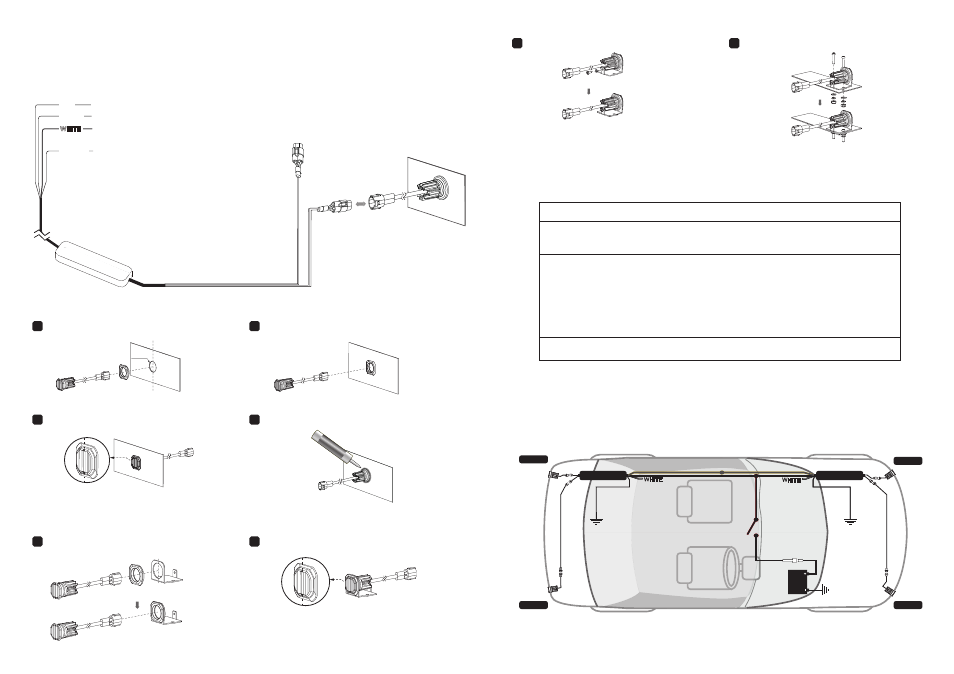

INSTALLATION - FLUSH MOUNT

Select mounting location and drill 1” (25.4mm) hole.

1

Front side of

mounting surface

lighthead

mounting

grommet

NOTE: recommended mounting

surface thickness is 0.8~2.0mm

Ø25.4mm

Ensure that triangle marks on the lens are aligned vertically.

3

Front side of

mounting surface

lens

From the front side, install MOUNTING GROMMET

into the hole, and then insert LIGHTHEAD.

2

Front side of

mounting surface

lighthead

Where necessary, apply silicone on the back side to prevent

from rotating.

4

INSTALLATION - BRACKET MOUNT (sold-separately)

Ensure that triangle marks on the lens are aligned vertically.

2

lens

To +VDC (fuse12V@3A / 24V@2A)

To Chassis Ground

RED

BLACK

YELLOW

For DIM Mode

Connect WHITE wire to +VDC for DIM Mode

NOTE: Make sure to cover all unused bare wires.

to lighthead or

extension cable

For Synchronization & Flash Patterns

Connect YELLOW wires of all Kits together for synchronization

*All kits must be set at the same pattern

For Flash Pattern change, momentarily apply

YELLOW wire to +VDC:

· once for next pattern · quickly three times for reset

For Flash Modes:

1. Apply +VDC to

RED and YELLOW wires simultaneously

to enter Flash mode.

2. Remove YELLOW wire from +VDC and momentarily

apply to +VDC to change Modes:

3. Exit Flash mode by removing +VDC.

Mode 1 = Head1 alternate Head2

Mode 2 = Head1&2 flash simultaneously

Back side of

mounting surface

From the front side, install MOUNTING GROMMET

into the hole, and then insert LIGHTHEAD.

1

lighthead

mounting

grommet

Front side of

mounting bracket

Back side of

mounting surface

to controller or

extension cable

silicone

(user supplier)

SILICONE

SILICONE

Secure LIGHTHEAD onto BRACKET with screw.

3

screw

Back side of

mounting bracket

Secure BRACKET onto mounting surface with screws.

4

mounting

surface

screws

mounting

surface

3

WIRING 2 KITS TOGETHER

Below is an illustration of wiring 2 kits together. In this configuration, Heads 1&3

flash together and Heads 2&4 flash together.

· If Flash Mode 1 is selected: Heads 1&3 will alternate with Heads 2&4.

· If Flash Mode 2 is selected: all Heads 1&2&3&4 will flash simultaneously.

NOTE: To have Heads 1&4 alternate with 2&3,

simply reverse the lighthead outlets on one of the

Controllers; (both kits must be in Flash Mode 1).

*refer to Flash Patterns chart on opposite page.

NOTE: Controller mounting area varies from vehicle to vehicle. (Illustration not to scale)

RED

YELLOW

BLACK

ON/OFF

CHASSIS

GROUND

EXTENSION CABLE

to GND

BLACK

EXTENSION CABLE

to GND

Unit1 Controller

Unit2 Controller

HEAD 1

HEAD 2

HEAD 3

HEAD 4

12V@3A / 24V@2A FUSE

(user-supplied)

Power Requirements

CURRENT DRAW

Maximum: 2.4 amp @12VDC / 1.2 amp @24VDC

Average: 1.2 amp @12VDC / 0.6 amp @24VDC

1. Single-2Hz

2. Double-R65

3. Triple-2Hz

4. Quad-2Hz

5. Random

6. Single

7. Double

FLASH PATTERN SELECTION

8. Quad

9. Quint

10. Mega

11. Ultra

12. Single-Quad

13. Single H/L

14. Steady

NOTE: Flash Pattern #2 must be selected to conform with requirements of ECE Regulation 65.

A single lighthead is approved, so both simultaneous and alternating flashing meets R65.

Any one of the 14 Flash Patterns may be selected by using the yellow wire to scroll through the

patterns. Momentarily apply the yellow wire to +VDC to switch to the next pattern. The following

patterns are available.