Troubleshooting, Maintenance, Warning – Code 3 90 Series Strobe Beacon User Manual

Page 5

5

Troubleshooting

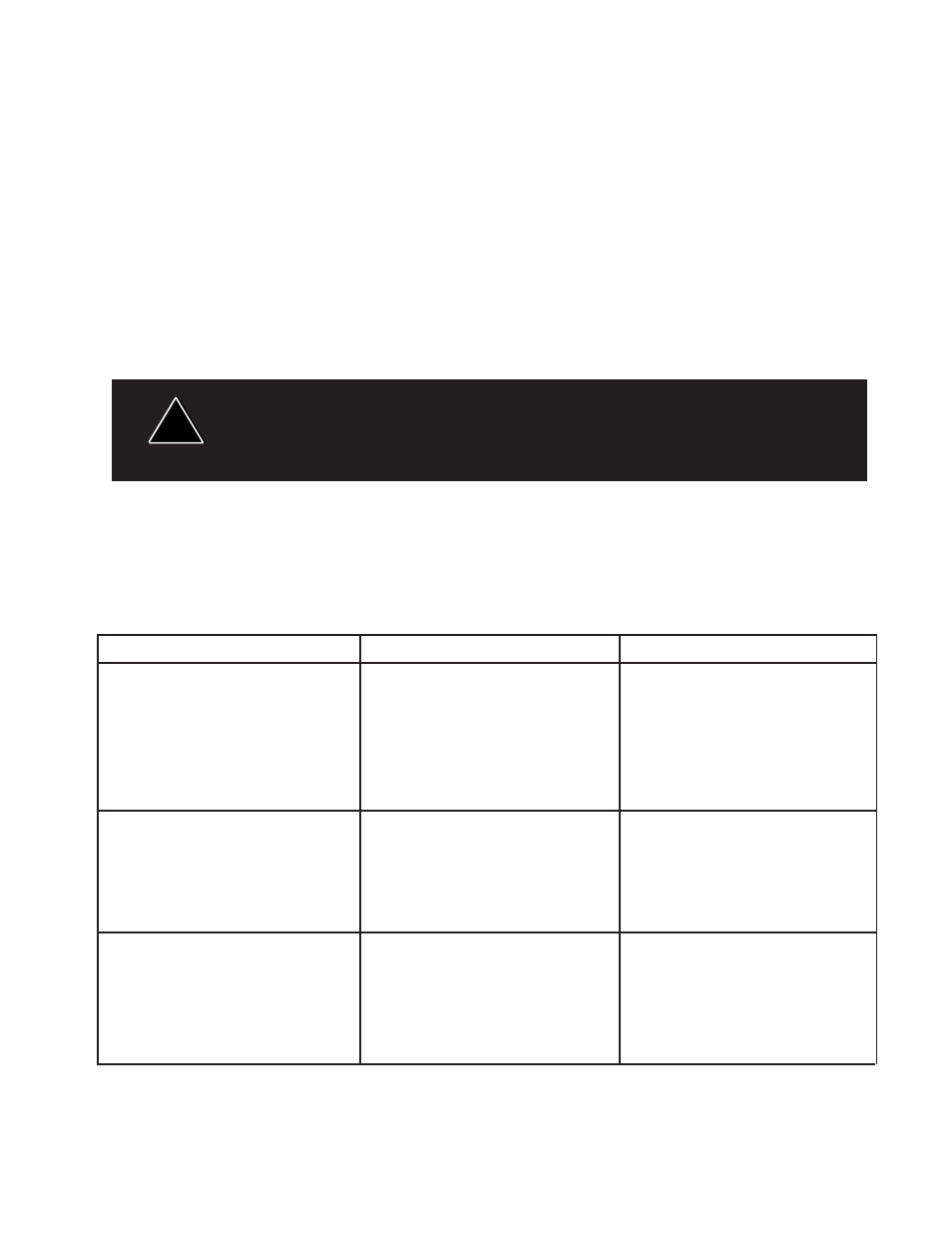

PROBLEM

PROBABLE CAUSE

REMEDY

a.) Unit power leads hooked up backwards.

b.) Output capacitor shorted.

c.) Flashtube worn.

d.) Flashtube polarity backwards

a.) Fuse not proper ampere rating.

b.) Wiring to unit shorted.

c.) Power supply failure.

a.) Flashtube worn.

b.) Output capacitor worn.

c.) Jumpers in wrong position (variable

flash only).

No Output

External Fuse Blows

Improper Flash Pattern

a.) Reverse power leads.

b.) Return for service.

c.) Replace flashtube.

d.) Reverse flash tube.

a.) Replace with proper sized fuse.

b.) Replace wiring to unit.

c.) Return for service.

a.) Replace flashtube.

b.) Return unit for service.

c.) Reset jumpers (variable

flash only).

Strobe lamps are extremely hot! Allow to cool completely before attempting to remove. Gloves and eye

protection should be worn when handling strobe flashtubes as they are pressurized and accidental breakage

can result in flying glass. High voltages and/or temperatures are present inside of strobe units. Disconnect from

power and wait 10 minutes prior to servicing.

WARNING!

!

Maintenance

The Model 99XXX, 98XXX, 92XXX and 95XXX strobes have a field replaceable Xenon flashtube. (See parts list and exploded view for

part numbers) The flashtube snap mounts onto the printed circuit board. Care should be taken to ensure that the tube holder guide pins

are inserted into the printed circuit board and that the base of

the tube holder is flush with the printed circuit board. Do not remove the circuit board from the base. Service the unit in dry locations.

CAUTION: Unit contains high voltages and high temperatures, disconnect from power and wait 10 minutes before servicing.