Magnetic mounting stanchion mounting, Permanent-resilient mounting, Warning – Code 3 300 Series Beacon User Manual

Page 3

1) Rust Stains: The magnetic mount is not intended as a permanent mounting for the

beacon. Long duration usage of any magnet will expose the high iron content of the steel

causing rust. The device should be removed when not used to prevent rust stains. Metallic

debris collected by the magnet will also contribute to rust stains. Insure that the magnet is

kept clean.

2) Surface rust stains can usually be removed with chrome polish, available at most auto

part stores.

3) As with any magnetically-mounted warning device, its use on the exterior of a moving

vehicle is at the sole discretion and responsibility of the user.

This magnetic mount product provides a secure, temporary installation in most circum-

stances and is recommended for stationary use only. For maximum warning signal, mount

the beacon on the highest possible flat, level surface of the vehicle.

WARNING!

!

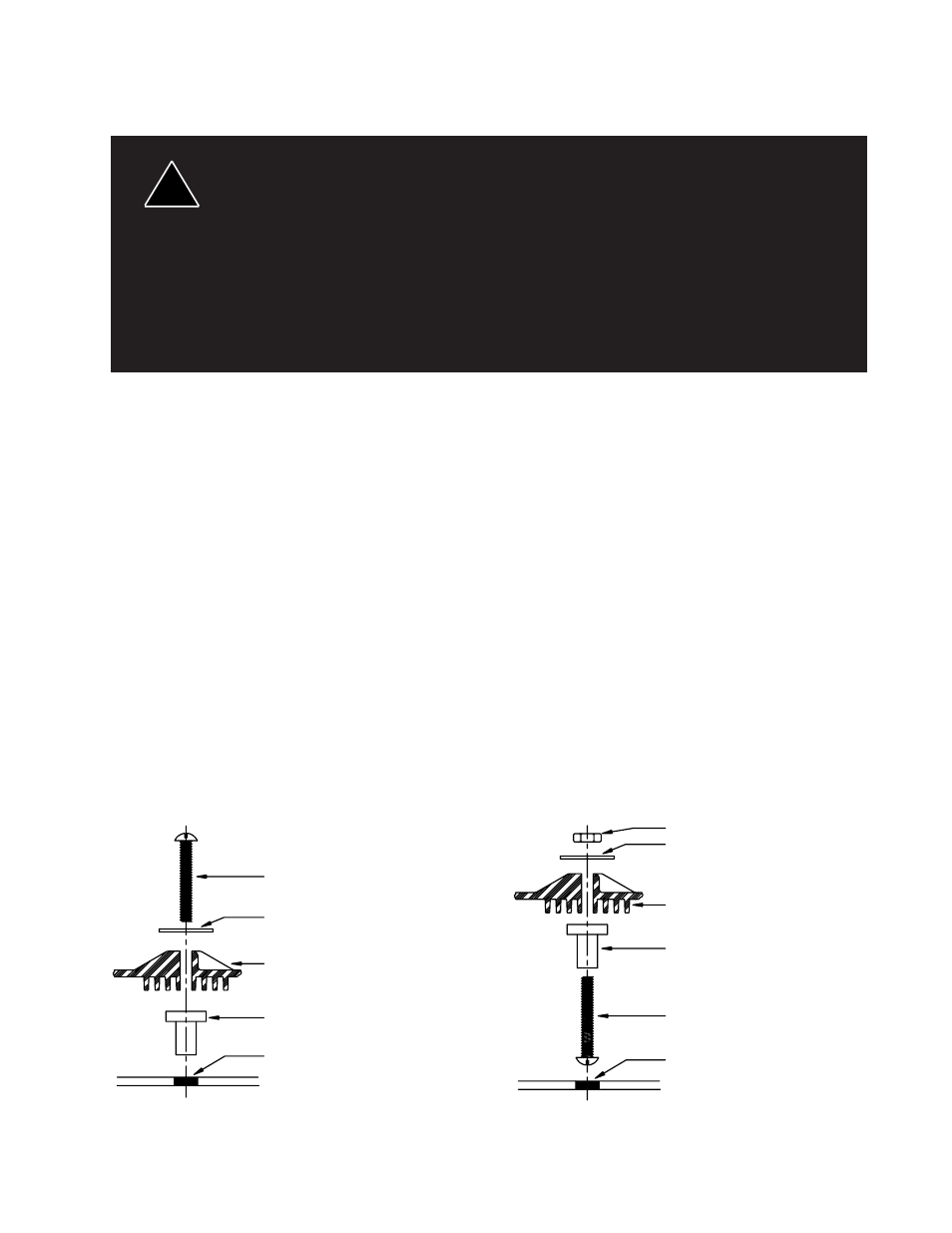

3/8" Dia. Hole on

5 1/2" Dia. Bolt Circle

#10-32 x 1 1/2" Screw

3/8" Rubber

Threaded Insert

Mounting Boss on

Beacon Base

1" Dia. Flat Washer

#10-32 Nut (User Supplied)

FIGURE 2

3/8" Dia. Hole on

5 1/2" Dia. Bolt Circle

Mounting Boss on

Beacon Base

1" Dia. Flat Washer

FIGURE 1

3/8" Rubber

Threaded Insert

#10-32 x 1 1/2" Screw

3

Magnetic Mounting

Stanchion Mounting

The 310

TM

Beacon is available with factory installed threaded flanges, 1/2” NPT or 3/4” NPT. Route the wiring as

described above and make the recommended connections. Guide user wiring through the pipe and terminate

securely to the power lead and ground wires of the Mode 310 Beacon. Fasten the flange mount beacon onto the

pipe by hand until secure. DO NOT OVERTIGHTEN!

Permanent-Resilient Mounting

Locate the Model 310 Beacon on the highest possible level surface on the vehicle for the maximum warning

signal. Caution! When drilling into any vehicle surface, make sure that each side is free from anything that

could be damaged (i.e., electrical wires, fuel lines or vehicle upholstery). Use the three mounting bosses of the

beacon base as a template to establish pilot holes. Drill three equally spaced 3/8” holes on a 5-1/2” dia. bolt

circle. See Figure 1. Locate the mounting hardware as illustrated and insert into the 3/8” holes. The correctly

installed rubber-threaded insert is a watertight and shock-resistant mount which will increase the effectiveness

and long life of the product. Do not overtighten the screws! In applications where the protruding screw enters

the passenger compartment, the screw can be reversed to minimize the risk of personal injury on the protruding

screw threads. See figure 2. Do not tighten nut until hardware is positioned properly.