Autotech 10.525.1128K Rear 28mm Lightweight Swaybar, Mk2/Mk3 Models User Manual

Page 2

4. Mark the axlebeam's crossmember for the hole locations using the distance you measured

in step 1. The holes should be centered left-to-right. Use the tape to measure 1.5 inches up

from the leading edge of the crossmember. The holes should end up just below the center

on the lower angled face of the beam.

5. Drill the two 1O.5mm (13/32" - 27/64") holes in the crossmember. It is a good idea to drill a

pilot hole first so that the larger drill bit does not have to work so hard.

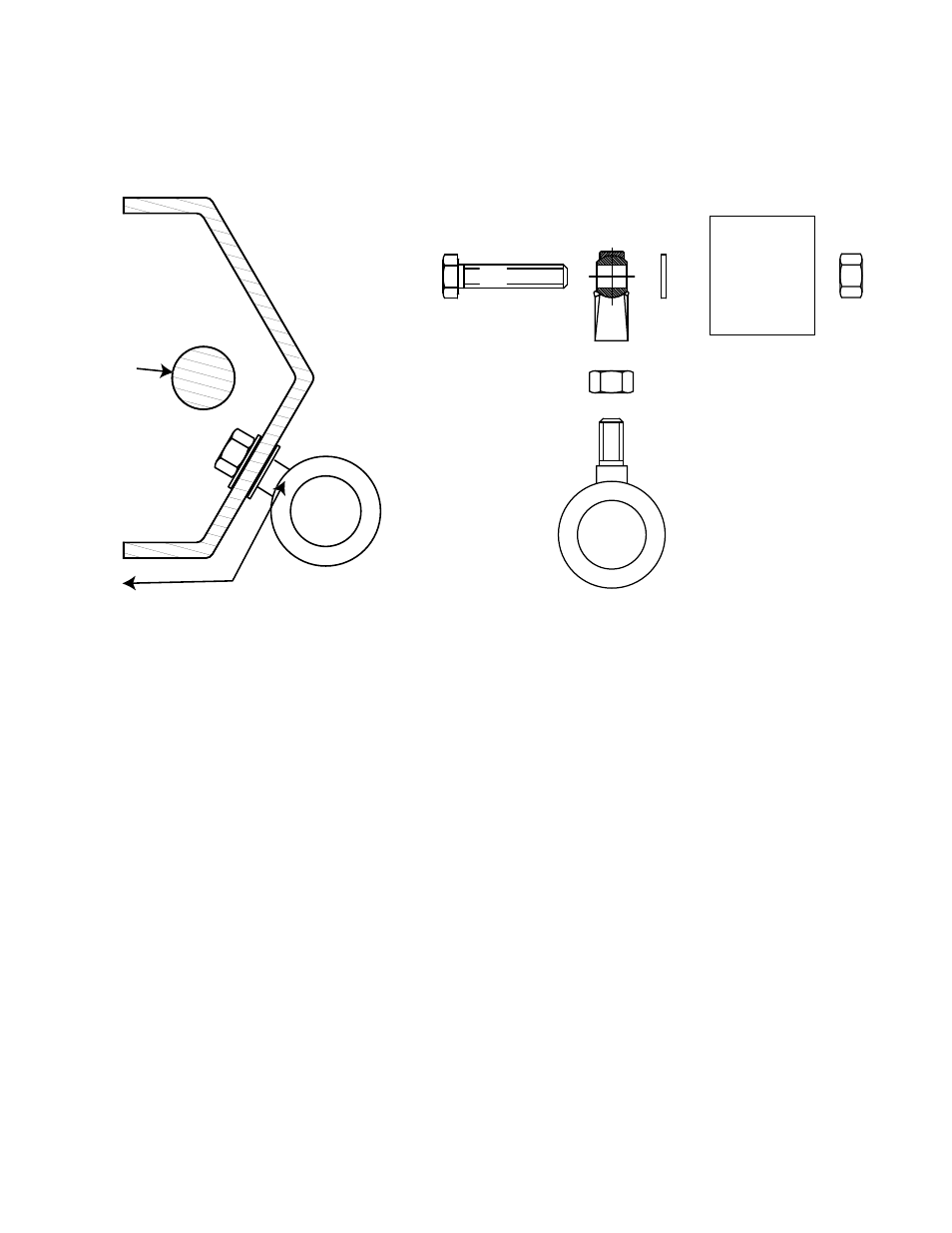

6. Thread the remaining two ring mounts (on A2/A3: with their jam nuts) into the rod ends.

Do not tighten them as yet.

7. Push each end of the swaybar into the end bushings. A small amount of silicone lubricant or

a film of moly grease applied to the bar end and bushing eases the task.

8. Now swing the swaybar forward in order to push the inboard mounting studs through the

drilled holes in the crossmemeber. Be sure to capture a washer on each side of the hole

before attaching each inboard mount with the nylock nut.

9t. Go back and tighten the jam nuts against the rod ends (A2/A3 only). Once that is done,

recheck all fasteners to be sure they are tightened properly.

1.5 in

factory bar

rear axlebeam section - side view

rear shock

mount

factory nut

new longer bolt

rod end

washer

jam nut

ring mount

with bushing

rear view of endlink assembly