Autotech 10.525.1128K Rear 28mm Lightweight Swaybar, Mk2/Mk3 Models User Manual

Installation instructions

A

U

T

O

T

E

C

H

Phone 949.240.4000 Fax 949.240.0450

32240-E Paseo Adelanto, San Juan Capistrano, CA 92675

Part Number: 10.525.1128K

Description:

Non-Adjustable rear swaybar installation for A2 & A3 chassis

Notes:

These performance swaybars utilize Autotech’s unique sliding endlink design

that prevents binding of the bar (and preloading of the suspension) due to

locational differences between the mounting points of the rear suspension and the

swaybar itself.

TOOLS REQUIRED:

PARTS LIST:

1. jackstands

1. rear swaybar

2. electric drill and 1O.5mm (27/64")bit

2. (4) poly bushings

3. silicone lubricant

3. (4) steel ring mounts

4. metric wrenches, 13 to 17mm

4. (2) 1Omm rod ends

5. tape measure

5. (6) 1Omm hardened washers

6. moly grease

6. (2) 1Omm thin jam nuts (1128K only)

7. (2) 1Omm nylock nuts

8. (2) M10x90 shock bolts

Procedure:

1. Apply a generous amount of waterproof grease to the inside of the bushings, and some sili-

cone spray along each of the bends on the swaybar.

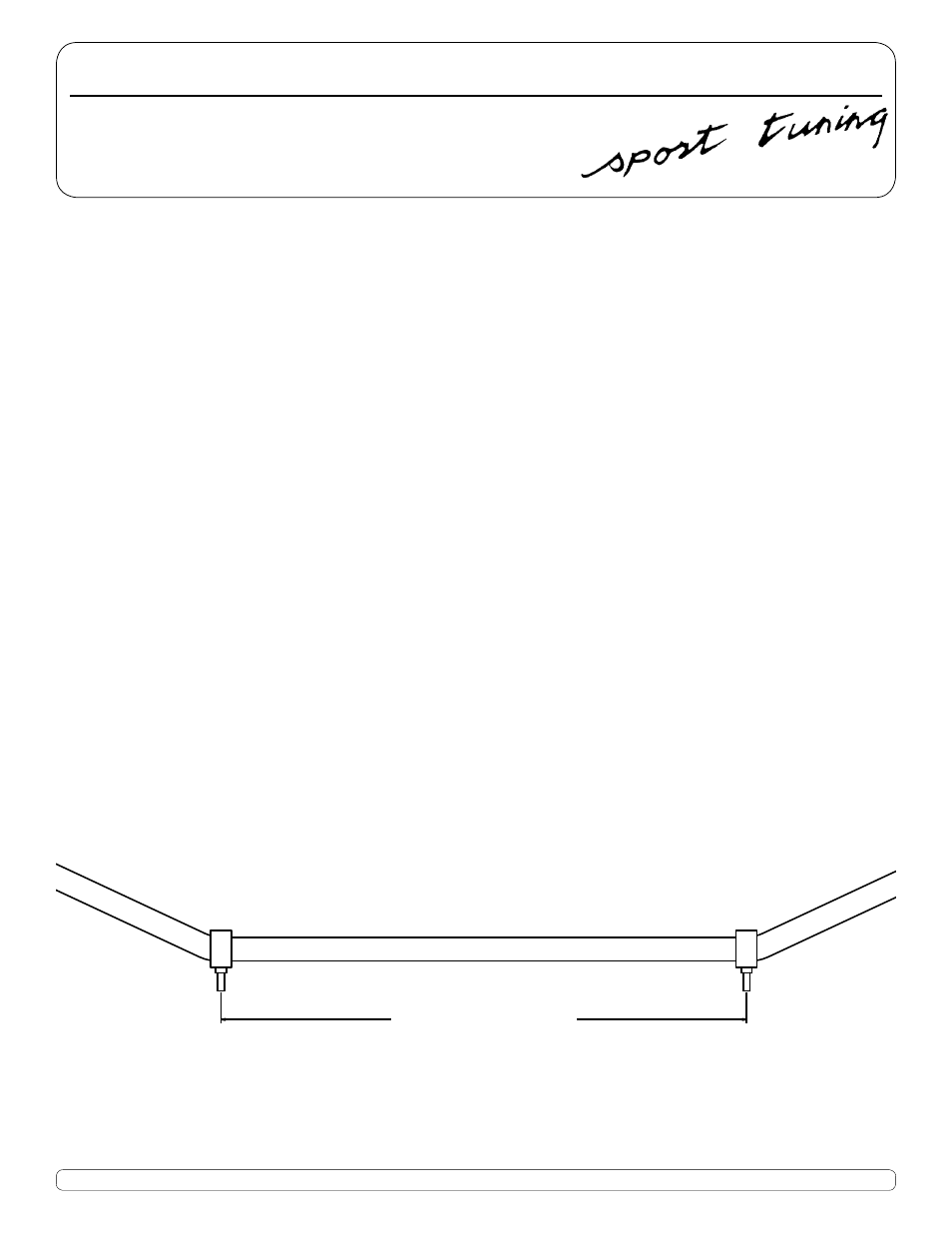

2. Slide the two inboard mounts onto the swaybar and push them past both bends so that

they end up on the middle, straight section of the swaybar. The inboard mounts will be

installed on the axlebeam when they are as far apart from each other as possible with-

out overlapping any of the bends on the bar. Measure, and take note of this distance.

The distance from stud to stud on the inboard mounts should be approximately as fol-

lows:

A2/A3 Chassis 29 inches

A4 Chassis

25 inches

3. Raise the rear of the car and place it on jackstands. Be sure that the car is in gear, the

front wheels are chocked, and that it cannot roll.

www.autotech.com

A2/A3 = 29.0 in

A4/B5 = 25.0 in

Installation Instructions