Auger clutch adjustment, Shift rod adjustment, Carburetor adjustment – Craftsman 247.885680 User Manual

Page 20: Service & adjustment

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

1 1

SERVICE & ADJUSTMENT

If adjustment is necessary, loosen the lock nut on the

traction drive cable and thread the cable in o ■ out as

necessary. Tighten the lock nut to secure the cable

when correct adjustment is reached. Reassemble the

frame cover.

•

NOTE:

If you placed plastic under the gas ■^ap, be

certain to remove it.

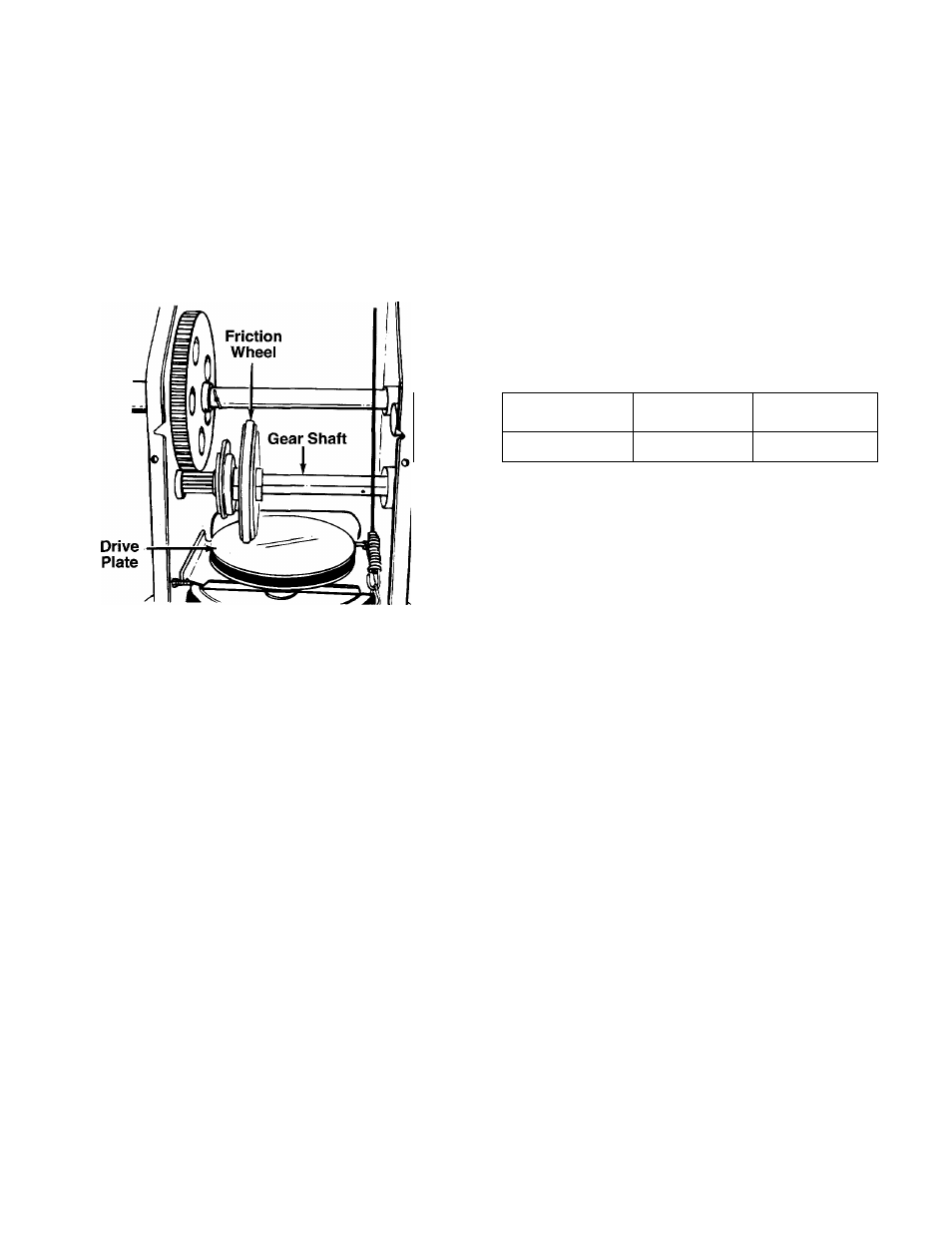

FIGURE 24.

AUGER CLUTCH ADJUSTMENT

To adjust the auger clutch, refer to Final Adjustment

section of Assembly Instructions.

SHIFT ROD ADJUSTMENT

To adjust the shift rod, remove the hairpin clip and flat

washer which secure the shift rod to the sf ift arm

assembly. Refer to figure

8

. Adjust as specified in

Assembly Instructions.

CARBURETOR ADJUSTMENT

A

WARNING:

IF

ANY

ADJUSTMENT«

ARE

MADE

TO

THE

ENGINE

WHILE

THE

ENGINE

IS

RUNNING

(E.G.

CAREIURE-

TOR),

KEEP

CLEAR

OF

ALL

MOVING

PARTS. BE CAREFUL OF HEATED SUR

FACES AND MUFFLER.

Minor carburetor adjustment may be required lo com

pensate for differences in fuel, temperature, altitude

or load.

Never attempt to change maximum engine spead. It is

pre-set at the factory and should be changed anly by

a qualified service technician who has the necessary

equipment.

5 H.P. ENGINE

Idle Speed Adjustment.

This screw is located on top

of the carburetor and contacts the throttle. To initially

pre-adjust this speed, back out the screw, then turn in

until the screw just touches the throttle lever, then turn

screw in 1 turn. When the engine is run, the final idle

R.P.M. can be adjusted with a tachometer.

Idle and Main Adjustment.

Turn these adjustment

screws in finger tight, then back them out to the pre

set figure on the chart.

TECUMSEH CARBURETOR PRE-SETS

ENGINE

MAIN

IDLE

MODELS

PRE-SET

PRE-SET

5 H.P.

1-1/4

1

Final Carburetor Adjustments

Allow engine to warm up to a normal running temper

ature. With engine running at maximum recom

mended R.P.M., loosen main adjustment screw until

engine starts to cut out. Then turn screw opposite

direction until engine starts to cut out. Note the num

ber of turns from one extreme to the other. Loosen

screw to a point midway between the extremes.

After the main system is adjusted, move the speed

control lever to the idle position and follow the same

procedure for adjusting the idle system.

Test the engine by running it under a normal load.

The engine should respond to load pick-up immedi

ately. An engine that “dies” is too lean.

An engine which ran rough before picking up the load,

is adjusted too rich.

If adjustment seems too “touchy” check float for prop

er setting and for sticking.

8 H.P. ENGINE

Preset the carburetor by turning both idle and main

adjustment screw closed (clockwise) fingertight. Open

the main adjustment screw

2

turns (counterclockwise)

and the idle adjustment screw 1 -3/4 turns.

Generally, the engine will perform well with these set

tings. If further adjustment is required, perform the fol

lowing adjustments with the engine running and fully

warmed up.

With speed control lever at idle or slow speed, turn

the idle adjustment screw slowly, clockwise

1/8

turn at

a time until the lean drop off point is reached. (The

engine will miss and run erratically due to lack of fuel.)

Now turn the screw counterclociwise 1/4 to 3/8 turn

from that position. This will be the best setting.

20