Operation cont – Craftsman 286.25574 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION cont

CUTTING ALL MATERIALS cont.

MAXIMUM STOCK SIZE AND FEED RATES

C/StYPE

MAX.SÍZE

WAX

«ATERIAIS (CROSS SECTION THlCKMESS

AVERAGE

BLADE UFE

AVERAGE

TÍME OR FEED

Hollow Pips

ColvoAbicid Imn TWn

2B5 cuts

2

GSfic

Square

Charmol

M.S

l/S'ln,

105 cuts

aoSfic

^pmJñum

\Un.

HB-in.

<4000 cuts

5Soc

Channel

F

MS

VB4(i

S5 cuts

30 See

Shsot Motel C

M.S.

1

/

í

M

r

.

GO fest

4,3 Irtch/mln

Aluminum

t/04m

QSißct

102

Inch/mln

Stud

Wood (Pina)

2 X 44n.

1

%-ln.

45S0 cuts

11 Soc

Pips

Plastic (PVC)

IVlrt.

3/l^ln.

6

Soc

Ps„ Avorags blade liia Indlcaios msulla oi parfomtanca tool In carticulsr iypa of tOQt maiertal c& par the abovo labio- Howaveir Uia

fosulia may vary If iho cams blada Is usad on a comblnaOon or lislad malodata.

DUTY CYCLE

30 minutes on 10 minutes off duty cycle refers to short-time operation. Short

time operation denotes operation under norma! load for a specified period and

material, starting cold, the Interval between each period of operation being sufficient

to allow the tool to coo! down approximately to room temperature.

Cutting other materiafs may require even more special handling. These include

cutting aluminum, copper, stainless steel and cast Iron or shaped plates

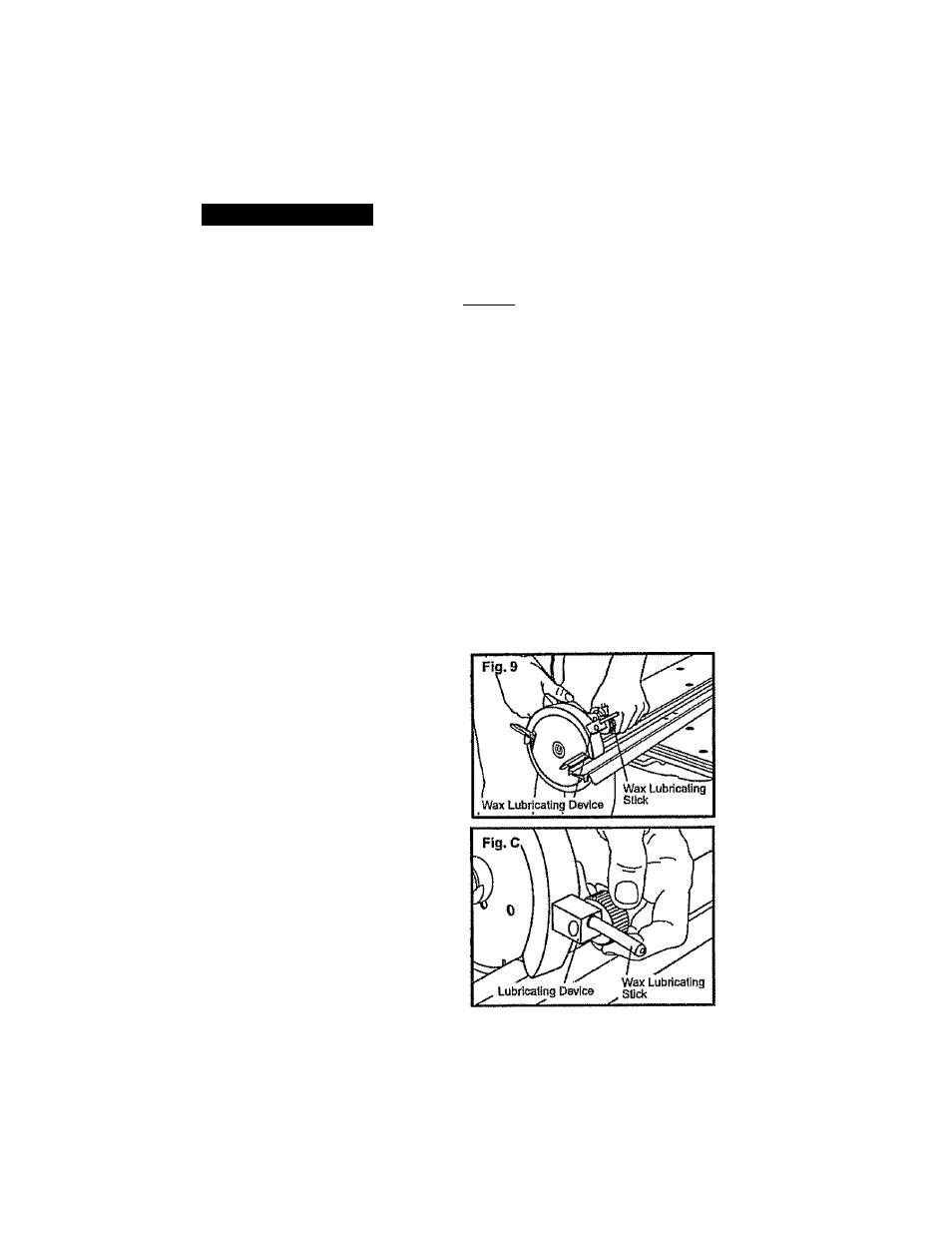

Cutting Aluminum, Copper, Stainless

Steel and Cast Iron up to 1/8-in. thick,

(See Fig, 9).

1. ALWAYS use the wax lubricating device

(included) when cutting these materials

because they have a tendency to soften

and adhere to the blades.

LUBRICATING INSTRUCTIONS

(See Figure C)

The blades of your Twin Cutter saw are

equipped with “dry cut teeth that under

normal cutting conditions do not need to

be lubricated. However, in extreme cutting

conditions, such as when you are sawing

into aluminum, copper, stainless steel and

cast Iron, the wax lubricating device should

be used.

1. Insert wax iubricating stick into wax

lubricating device.

2. Turn feeder wheel to apply lubricant to blade. A 1/4 turn should provide

adequate lubrication,

.jg