To start the engine, Operation, Fig. 18 – Craftsman 580.751651 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION

ADD ENGINE OIL;

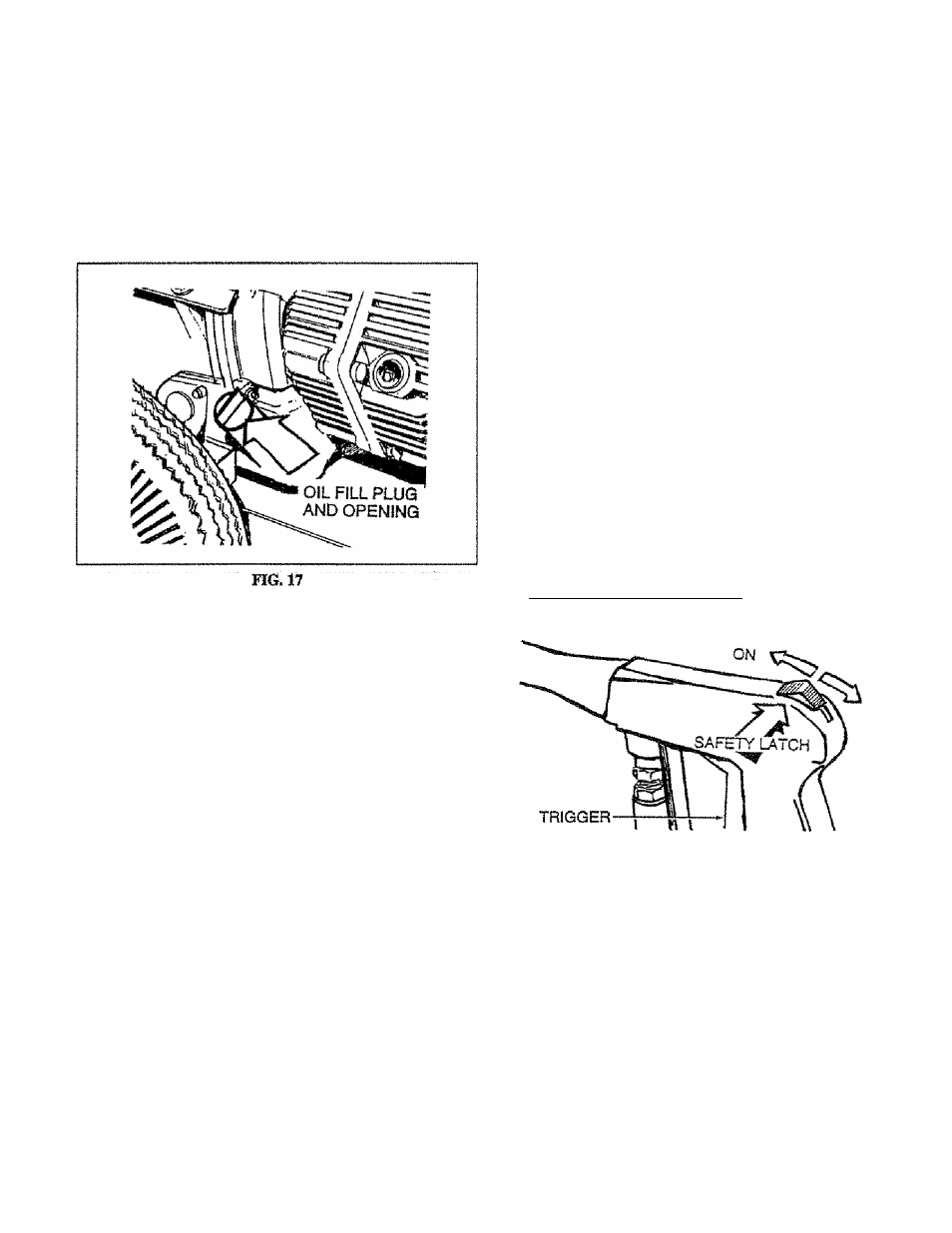

• Place pressure washer on a level surface and remove

one of the yellow Oil Fill Caps (Fig. 17) and add engine

oil from the enclosed bottle until level is at point of

overftowing.

Check

engine

oil

level

before

starting

each time thereafter. If oil level is below point of

overflowing, fill to proper level. Crankcase oil capacity

is about 620ml or 21 fluid ounces.

A

CAUTION: ANY ATTEMPT TO CRANK OR START

THE ENGINE BEFORE IT HAS BEEN PROPERLY

SER\RCED WITH THE RECOMMENDED OIL RE

SULTS IN AN ENGINE FAILURE.

ADD GASOUNE;

A

CAUTION; DO NOT OVERFILL imE FUEL TANK.

ALWAYS ALLOW ROOM FOR FUEL EXPANSION.

A

WARNING: NEVER FILL FUEL TANK INDOORS.

NEVER FILL FUEL TANK WHEN ENGINE IS RUN

NING OR HOT. DO NOT LIGHT A CIGARETTE OR

SMOKE WHEN FILUNQ FUEL TANK.

•

Use

regiflar

UNLEADED

gasoline

with

the

pressure

washer engine. Regular leaded gasoline may also be

used if UNLEADED is not available. Fuel tank capacity

is 1 U.S. gallon.

IMPORTANT:

IT

IS

IMPORTANT

TO

PREVENT

GUM

DEPOSITS FROM FORMING IN ESSENTIAL FUEL SYS

TEM PARTS SUCH AS THE CARBURETOR, FUEL FIL

TER, FUEL HOSE OR TANK DURING STORAGE. ALSO,

EXPERIENCE

INDICATES

THAT

ALCOHOL-BLENDED

FUELS (CALLED GASOHOL

OR USING ETHANOL OR

METHANOL)

CAN

ATTRACT

MOISTURE

WHICH

LEADS

TO SEPARATION AND FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAMAGE THE FUEL SYS

TEM OF AN ENGINE WHILE IN STORAGE. TO AVOID

ENGINE PROBLEMS, THE FUEL SYSTEM SHOULD BE

EMPTIED

BEFORE

STORAGE

OF

30

DAYS

OR

LONGER SEE “STORAGE” ON PAGE 18. NEVER USE

ENGINE

OR

CARBURETOR

CLEANER

PRODUCTS

IN

THE FUEL TANK OR PERMANENT DAMAGE MAY OC

CUR.

•

Clean area around fuel fill cap, remove cap.

•

Add “UNLEADED” regular gasoline, slowly, to fuel/

tank.

^

•

Install fuel cap and wipe up any spilled gasoline.

TO TURN ON VifASHER

•

Attach one end of a garden hose to a cold water source.

Water supply should not exceed 140°F (55°C).

•

Check that high pressure hose is attached to pump

outlet and that water supply is attached to pump inlet

•

Turn ON water.

•

Press trigger on gun and wand assembly to force air

from high pressure hose.

•

Start engine according to TO START THE ENGINE.”

TO START THE ENGINE

IMPORTANT;

DO

NOT

RUN

PUMP

WITHOUT

THE

WATER SUPPLY CONNECTED AND TURNED ON.

•

Start, store and fuel the unit in a level position.

•

Open fuel shut-off valve.

•

Press trigger on pressure washer wand to relieve high

pressure and/or purge the inlet hose of air.

•

Adjust safety latch on spray gun to the ON position.

This disables the trigger so you cannot inadvertently

actuate a high pressure spray (Fig. 18).___________________

f

OFF

FIG. 18

Locate the Run/Stop switch (Fig. 19 on Page 13) next

to the engine cylinder head and set it to RUN.

Close the choke to FULL position (Fig. 20 on Page 13)

by sliding it to far position in direction indicated by arrow

on air cleaner housing.

Turn

pressure

control

knob

counterclockwise,

two

turns from maximum pressure.

Grasp the starter grip and puil slowly until you feel

resistance. Then puil rapidly.

When engine starts, move choke lever to “RUN" posi

tion. If engine falls to start, move choke lever to “RUT

position and puil starter rope (maximum 2 pulls). ',

If engine fails to start, repeat the previous two stepsJ

12