Spark plug, Muffler, Flexible pump coupler – Craftsman 247.287751 User Manual

Page 14: Tire pressure

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Yearly

or

every

25

hours,

whichever

occurs

first,

remove the blower housing and clean the areas shown

in figure

21

to avoid overspeeding, overheating and

engine damage. Clean more often if necessary.

A

WARNING: PERIODICALLY CLEAN MUF

FLER AREA TO REMOVE ALL GRASS,

DIRT AND COMBUSTIBLE DEBRIS.

Clean Out

> Chaff and Dirt

FIGURE 21.

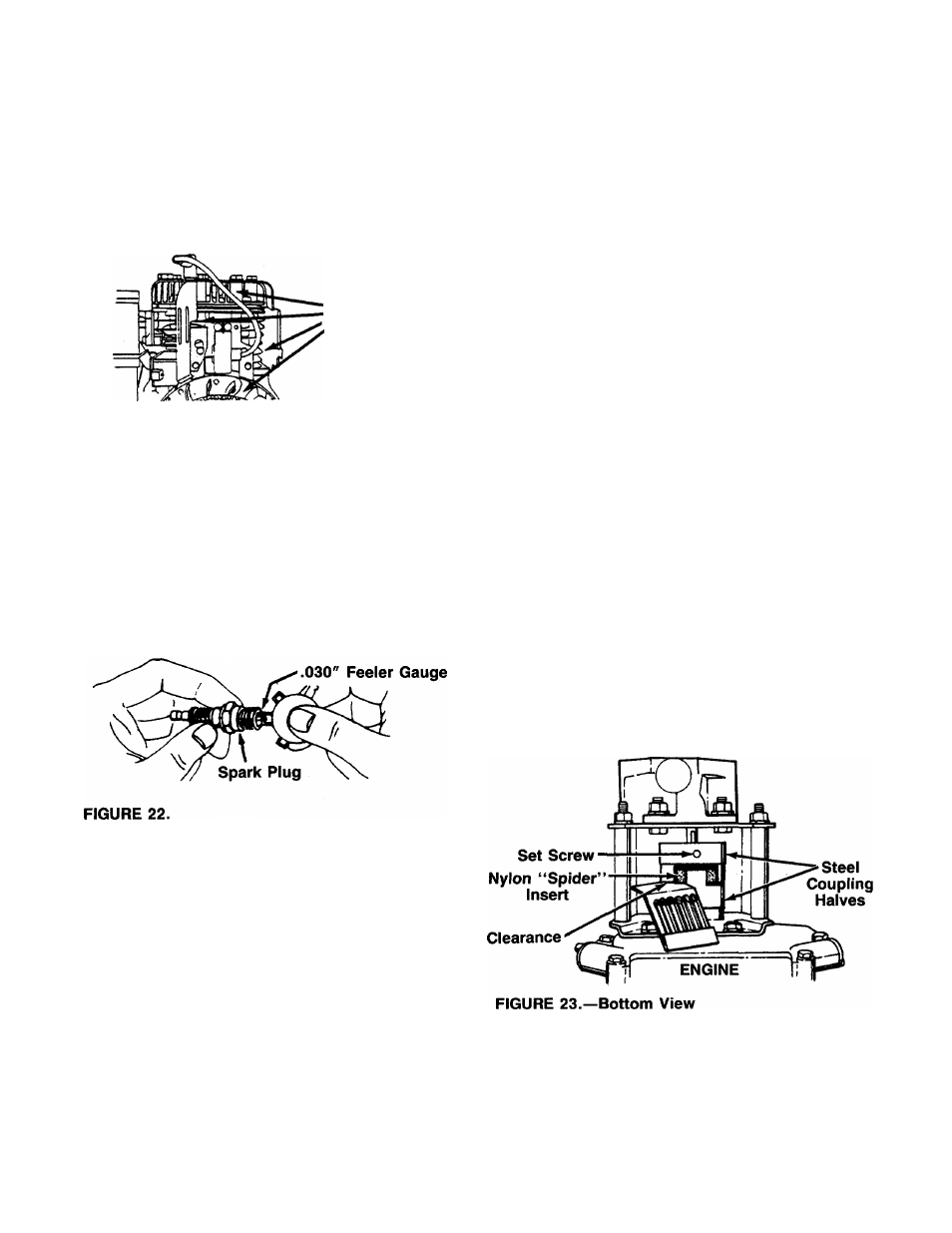

SPARK PLUG

The spark plug should be cleaned and the gap reset

to .030" at least once a season or every 50 hours of

operation. See figure 22. Spark plug replacement is

recommended at the start of each season. Refer to

engine parts list for correct spark plug type.

NOTE:

Do not blast clean spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with a commercial solvent.

MUFFLER

Do not operate the log splitter without a muffler or

tamper with the exhaust system. Damaged mufflers or

spark

arresters

could

create

a

fire

hazard.

Inspect

periodically, and replace if necessary. If your engine

is equipped with a spark arrester screen assembly,

remove every 50 hours for cleaning and inspection.

Replace if damaged.

FLEXIBLE PUMP COUPLER

The flexible pump coupler is a nylon “spider” insert,

located between the pump and engine shaft. The align

ment is very critical. Over a period of time, the coupler

will harden and deteriorate. For a replacement flexible

pump coupler, order part number 717-0891.

A

WARNING: NEVER HIT THE PUMP

SHAFT IN ANY MANNER, AS ANY BLOW

WILL CAUSE PERMANENT DAMAGE TO

THE PUMP.

When replacing the flexible pump coupling, proceed

as follows.

•

Place the coupling half onto the engine shaft. Make

certain there is clearance between the coupling half

and the engine. Tighten the set screw.

•

Mount the pump onto the coupling support bracket.

Tighten securely.

•

Carefully slide coupling half onto pump shaft (make

certain set screw is loose). Slide the key into place

on the shaft.

•

Install the nylon “spider” insert into coupling half on

the engine shaft.

•

Place the coupling shield in position on the hex bolts.

Rotate the keyway on the pump shaft so it is toward

the bottom.

•

Attach the coupling support bracket to the hex bolts,

carefully sliding the coupling half over the “spider”

insert. Secure coupling shield and coupling support

bracket with lock washers and hex nuts. Tighten

securely.

• Adjust the two coupling halves (steel) so there is be

tween .

010

" and .060" clearance between the two

halves (at least the thickness of a matchbook cover,

up to 1/16" maximum). See figure 23. Tighten the

set screw in the coupling half on the pump shaft.

NOTE:

Make certain proper clearance is obtained

before tightening set screw.

PUMP

TIRE PRESSURE

Check sidewall of tire for manufacturer’s recommended

maximum tire pressure. If this information does not ap

pear on your tire, maximum tire pressure under any cir

cumstances

is

30

p.s.i.

Equal

pressure

should

be

maintained on both tires.

14