Hydraulic filter, Beam and splining wedge, Hose clamps – Craftsman 247.287751 User Manual

Page 13: Engine lubrication, Air cleaner, Clean engine

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

to a suitable container. Refill using only Dexron II

automatic transmission fluid, as instructed in the “In

itial Preparation” section of this manual, page 9. Also,

make certain to change the hydraulic filter.

NOTE:

Drain the fluid and flush the reservoir tank and

hoses with kerosene whenever any repair work is per

formed on the tank, hydraulic pump or valve. Con

taminants

in

the

fluid

will

damage

the

hydraulic

components.

(Should

be

performed

by

your

SEARS

Service Center.

A

WARNING: USE EXTREME CAUTION

WHEN WORKING WITH KEROSENE, AS

IT IS AN EXTREMELY FLAMMABLE

FLUID.

HYDRAULIC FILTER

Change the hydraulic filter every 50 hours of operation.

Use only a 10 micron hydraulic filter. Order part number

723-0405.

BEAM AND SPLiniNG WEDGE

Lubricate both sides of the beam where it contacts the

splitting wedge with engine oil before each use to ob

tain years of service. However, normal wear will occur.

The wedge plate on the log splitter is designed so the

gibs on the side of the wedge plate can be easily re

moved and rotated and/or turned over for even wear.

Make certain to readjust the adjustment bolts so wedge

moves freely, but no excess space exists between the

wedge plate and beam.

HOSE CLAMPS

Check the hose clamps on the suction hose (attached

to bottom of the pump) for proper tightness before each

use. Check the hose clamps on the return hose at least

once a season.

ENGINE LUBRICATION

Your four-cycle engine will normally consume some oil;

therefore,

check

engine

oil

level

regularly—approxi

mately every five hours of operation and before each

usage. Stop engine and wait several minutes before

checking oil level. With engine level, the oil must be

even with the oil fill (refer to figure 12). Change engine

oil after the first five hours of operation, and every

twenty-five hours thereafter.

• Drain oil while engine is warm.

a. Remove oil drain plug. Refer to figure 12. Catch

oil in a suitable container.

b. When engine is drained of all oil, replace drain

plug securely.

• Refill with fresh oil. Above 32°, use oil labeled SAE

30W or 10W30. Below 32°, use oil labeled 5W20.

Capacity is

VA

pints. Refer to “Gas and Oil Fill-Up”

on page 9.

• Replace oil fill plug.

AIR CLEANER

The air cleaner prevents damaging dirt, dust, etc., from

entering the carburetor and being forced into the engine

and is important to engine life and performance.

Never run your engine without air cleaner complete

ly assembled.

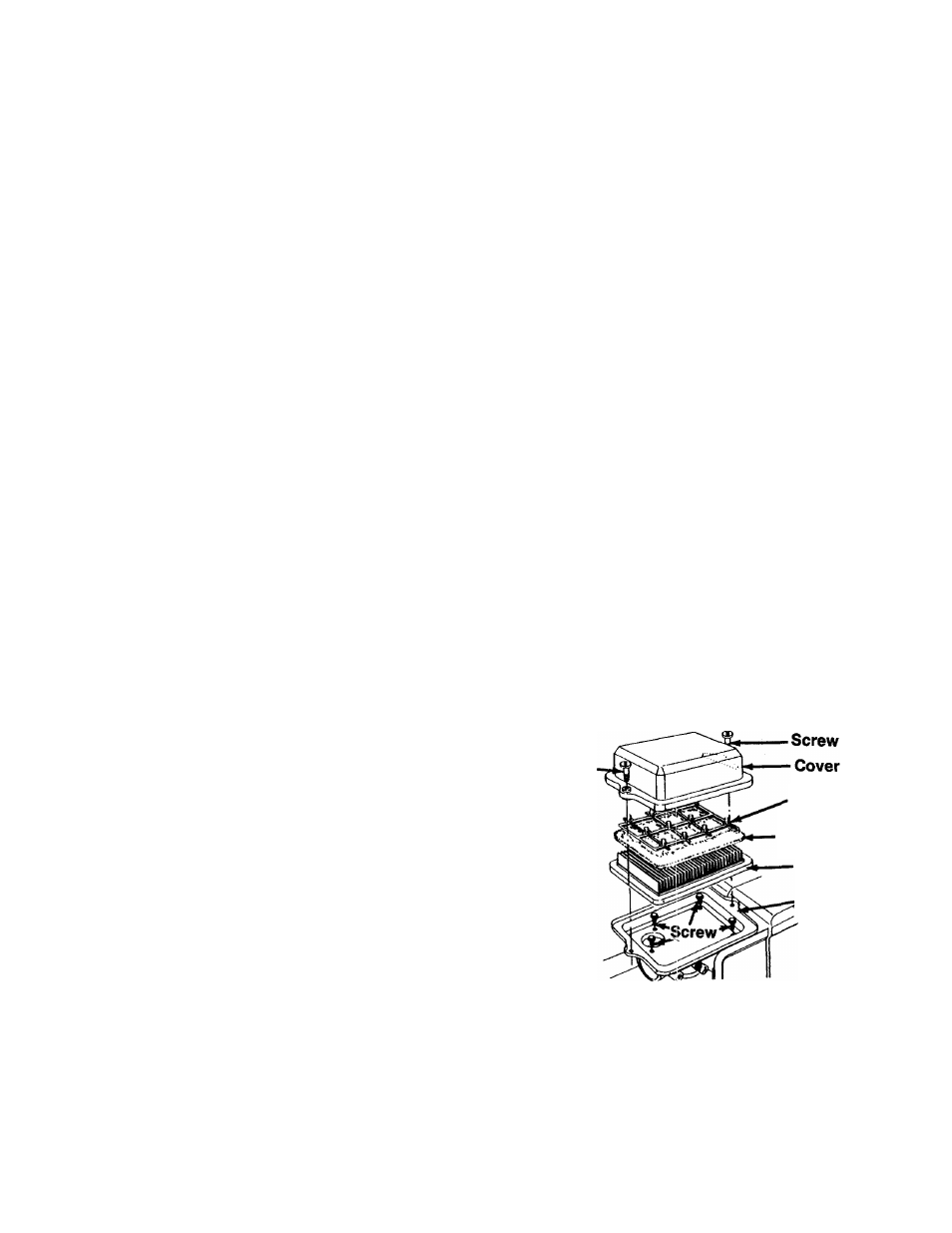

TO SERVICE AIR CLEANER:

Clean cartridge at three month intervals or every 25

hours, whichever occurs first. See figure 20. Service

more often under dusty conditions.

• Loosen screws and tilt cover as illustrated.

• Carfeully remove pre-cleaner and cartridge.

•

Clean cartridge by tapping gently on a flat surface.

If very dirty, replace cartridge and pre-cleaner or

clean as follows;

a.

Wash in a low or non-sudsing detergent and

warm water solution.

CAUTION:

Do not use

petroleum solvents such as kerosene to clean

cartridge.

b.

Rinse thoroughly with flowing water from inside

out until water is clear.

c.

Allow cartridge to stand and air dry

thoroughly

before

using.

DO

NOT

OIL

CARTRIDGE

OR

PRE-CLEANER.

DO

NOT

USE

PRESSURIZED

AIR TO CLEAN OR DRY CARTRIDGE.

•

Install cartridge and pre-cleaner. Then close cover

and fasten screws securely.

Screw

Spacer

Pre-Cleaner

Cartridge

Base

FIGURE 20.

CLEAN ENGINE

Clean engine periodically. Remove dirt and debris with

a cloth or brush. Cleaning with a forceful spray of water

is not recommended as water could contaminate the

fuel system.

13