Carburetor adjustment, Maintenance, Reservoir fluid – Craftsman 247.287751 User Manual

Page 12

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Hex Bolts

Bolts

FIGURE 18.

• Loosen the three hex bolts on top of the slide plate

(beneath the splitting wedge).

• Back the two adjustment bolts on the side of the slide

plate out

slowly

until the wedge assembly will slide

on the beam. Tighten the lock nuts securely against

the base of the slide plate to hold the bolts in this

position.

• Retighten the three hex bolts on top of the slide plate.

CARBURETOR ADJUSTMENT

A

WARNING: IF ANY ADJUSTMENTS ARE

MADE TO THE ENGINE WHILE THE

ENGINE IS RUNNING (e.g. CAR

BURETOR), KEEP CLEAR OF ALL MOV

ING PARTS. BE CAREFUL OF HEATED

SURFACES AND MUFFLER.

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude or

load.

NOTE:

A DIRTY AIR CLEANER WILL CAUSE ENGINE

TO

RUN

ROUGH.

BE

CERTAIN

AIR

CLEANER

IS

CLEAN

AND

ATTACHED

TO

THE

CARBURETOR

BEFORE

ADJUSTING

CARBURETOR.

DO

NOT

MAKE

UNNECESSARY

ADJUSTMENTS.

FACTORY

SETTINGS

ARE

SATISFACTORY

FOR

MOST

AP

PLICATIONS AND CONDITIONS.

Never attempt to change maximum engine speed. It

is pre-set at the factory and shouid be changed only

by a qualified service technician who has the necessary

equipment.

The Carburetor may need re-adjusting if engine lacks

power or does not idle properly. If adjustments are

needed, proceed as follows.

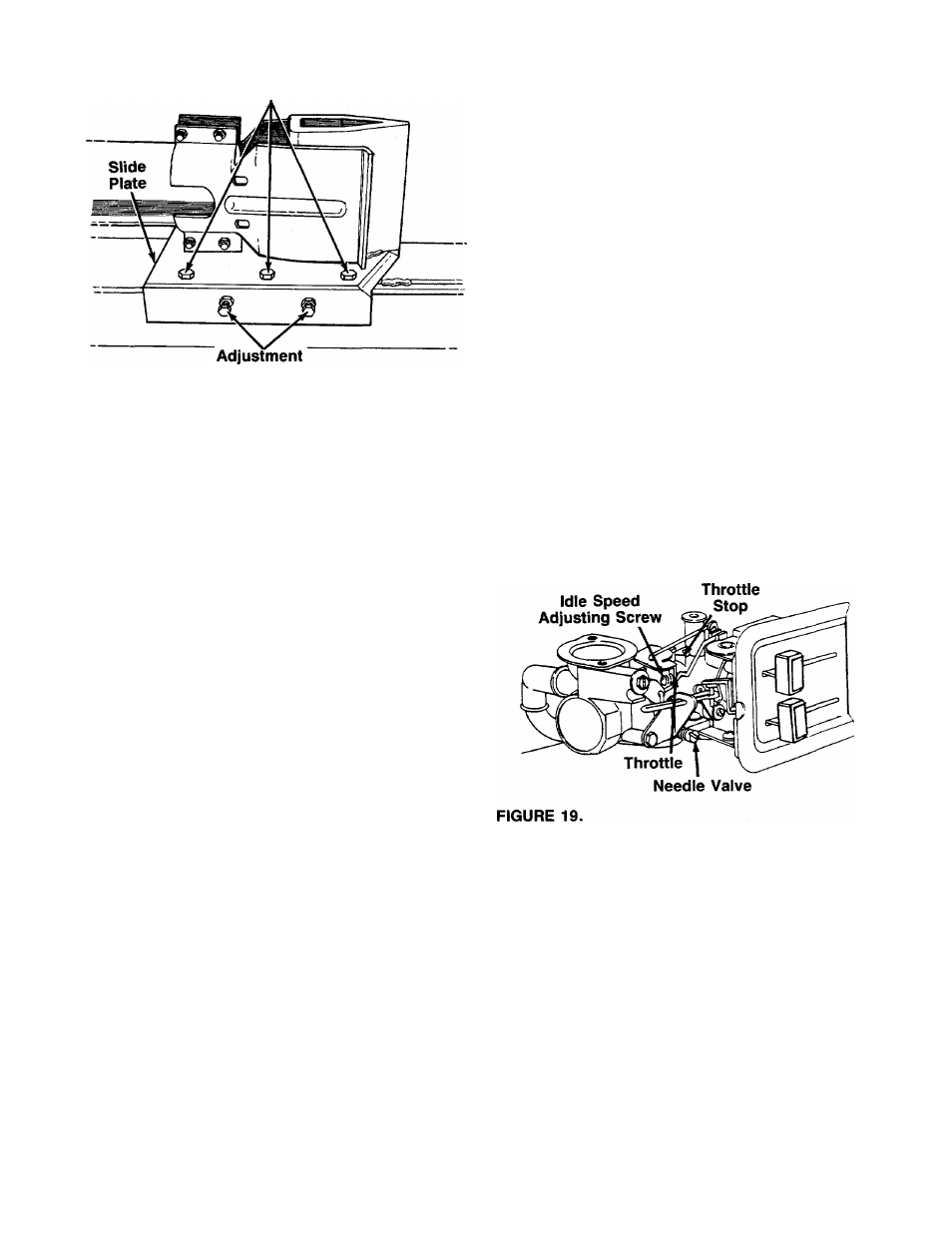

•

Close

needle

valve

(see

figure

19)

clockwise

() finger tight only. Forcing may cause damage.

Then open 1

V

2 turns counterclockwise (

).

a.

b.

Start engine and allow to warm for five minutes.

With throttle in FAST position, close needle valve

clockwise

().

until

engine

Starts

to

lose

speed

(lean

mixture).

Then

slowly

open

needle

valve

counterclockwise

( )

until

engine

JUST

BEGINS

to run unevenly. This mixture should be rich enough

for best performance under load.

Place throttle control in IDLE position:

If

engine

idles,

no

further

adjustment

is

necessary.

If engine idles too fast, turn idle speed adjusting

screw counterclockwise (

)

until slower speed

is obtained.

c.

If engine dies, turn idle speed adjusting screw

' A

turn clockwise (/^ ). Place throttle control in

FAST position and restart engine.

d.

Move throttle control to IDLE position. If engine

does not idle, repeat step c.

• Test the engine by splitting. If engine tends to stall

or die out, it usually indicates that the mixture is

slightly lean and it may be necessary to open (

f ~ \

)

the needle valve slightly to provide a richer mixture.

This richer mixture may cause a slight unevenness

in idling.

MAINTENANCE

A

WARNING: ALWAYS STOP THE ENGINE

AND DISCONNECT THE SPARK PLUG

WIRE BEFORE PERFORMING ANY

MAINTENANCE OR ADJUSTMENTS.

RESERVOIR FLUID

Check the hydraulic fluid level in the log splitter reser

voir tank before each use. Fluid level should be 1-1/2"

to 2” from the top of the tank.

Change the hydraulic fluid in the reservoir every 100

hours of operation. Disconnect the suction hose from

the bottom of the reservoir tank, and drain the fluid in-

12