Service and adjustments, Chain replacement (rg, 36,37,38 & 39) – Craftsman 358.351080 User Manual

Page 22

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE AND ADJUSTMENTS

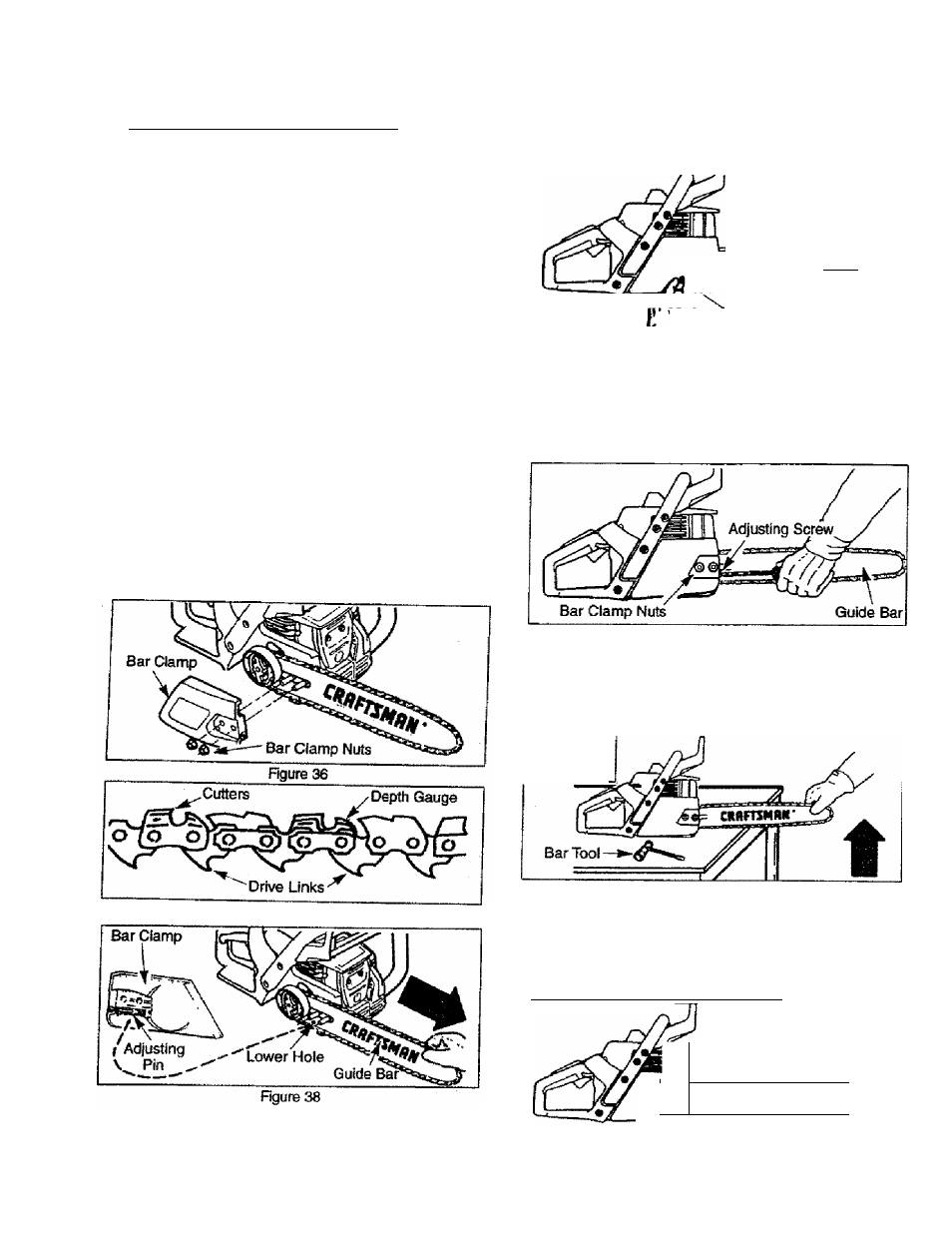

CHAIN REPLACEMENT (Rg, 36,37,38 & 39)

CAirnON:

Wear

protective

gloves

when

handling chain. The chain is sharp and can cut

you even when it is not moving.

It Is nonnal for a new chain to stretch. Because

of this initial stretch during the first 15-30

minutes of operation you should recheck your

chain tension freqti«ri% aid adjust the chain

tension as required. See chain tension sectkxi.

• Move on/stop switch to the

“Stop”

position.

• Replace ttte old chain vrtien it becomes worn or dafnaged.

• use only the Low-Kidd)ack replacement chain specified in the

repar parte list or as specified on the replacement bar and

chan decal located on the chain saw.

•

your Sears Service Center to r^ace and sharpen itKfl-

vldua! cutters for matcWng your chain.

• Loosen and remove the 2 bar damp nuts.

• Remove bar damp.

• R©nove the old diain. .

• Turn acfustir^ screw

hand oounterdodcwise until acjusting

pmust touches the stop.

• Slide guide bar behirfo dutch drum urrtil gukte bar stops

a^nst dutch drum sprodiet.

•

remove new chain from package. HdcJ chain vwtti the

cmvB (inks as shown in Foute 37.

• Place diain over and berand the dutdi.

• Rt tottom of drive links between teefo in sprocket nose.

• Frt chain drive links rito top of guide bar. Rgure 38.

•

9^1^ bar forward untii chain is snug in guide bar grooves.

• Now, instdi bar damp making sure the adfusling pin is posi-

toned in the lower hole in foe guide bar.

Rgure 37

Install bar clamp nuts and linger tighten only.

Do not

tighten

any further at this point

Now proceed to the 'Chain Adjustmaif secfion.

CRUroMBW

'Í I Bar Ciamp Nuts

F^ure 39

■ Rdl chain around guide bar to ensure kinks cfo not ewst

(rotates fredy}.

• Assure bar damp nds are loosened (fir^r light).

• Turn adjusfing screw dockwse until chain jist barely touches

foe bottom of guide bar.

• Roil diain around guide bar to ensure all links are in bar groove.

Figure 40

Lift up tip of guide bar to check for sag, release tip of guide bar,

then turn adjusting screw 1/4 turn dockvwse. Repeat fois step

until a sag does not exist

While lifting tip of guide bar. tighten bar damp nuts with foe bar

tool (provided). Torque tO-IStt-lbs.

Adjusting Screw

T/4 Turn

Figure 41

To check chain tension

• Use foe styewdiwer end of foe bar tool to move chain around

foe guide bar (Rgure 43).

• If d^n does not rotate, it is too tight - siighUy loosen bar

clamp nuts and turn adjusting screw 1/4 turn counterdock-

wise. Retighten bar damp nuts.

If chain is too loose, ft will sag beiow the pjíde bar (F^ure 42).

ft

Sag

JT2

kSKS;

-22

Fgure 42