Guide bar maintenance (fig. 28 & 29), Ui m lui nil, X" \ n n – Craftsman 358.351080 User Manual

Page 19: Customer responsibilities, Crbftsmhw

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CUSTOMER RESPONSIBILITIES

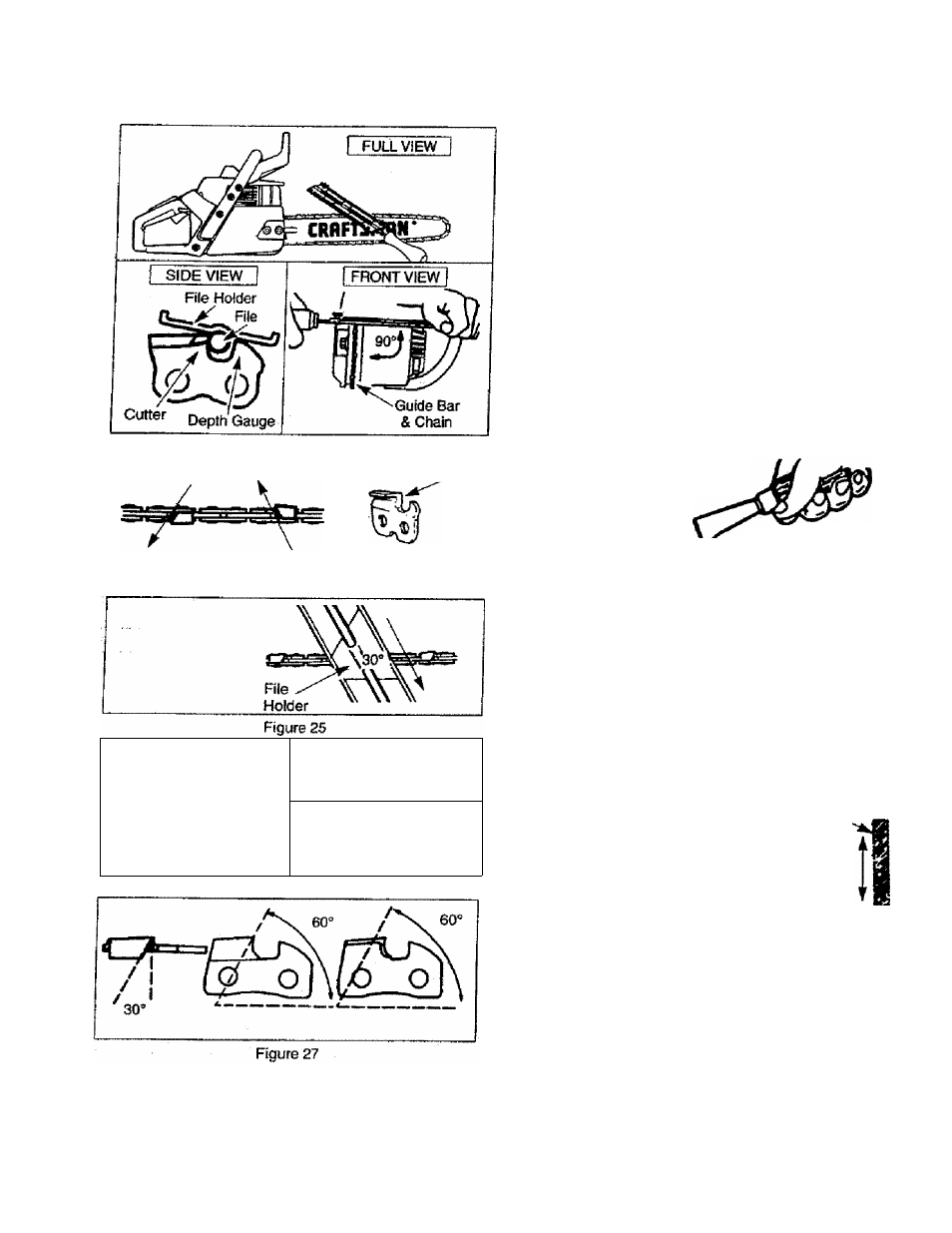

Figure 23

Inside

Outside

Figure 24

Figure 26

Cutters Same

Remove Damage

Length

x" \

n n

Side Plate Top Plate

GUIDE BAR MAINTENANCE (Fig. 28 & 29)

Conditions which require guide bar maintenance:

• saw cuts to one side or at an angle.

• saw has to be forced through the cut.

• inadequate supply of oil to the bar and chain.

.

Check the condition of the guide bar each time the chain is

sharpened. A worn guide bar wiii damage the chain and

make cutting difficirit.

• Move on/stop swKch to the “Stop” position.

• Remove bar and chain from saw.

• Clean all saw dust and any other debris from the guide

bar groove and guide bar lubrication hole. Figure 28.

• Lubricate guide bar hole sprocket after each use. Figure

• Buning of bar rails is a normal process of guide bar rail

wear. Remove these buns by filing guide bar rail side

edges square with a flat file. Figure 29.

• Restore square edges to an uneven rail top by filing with

a flat file. Rgure 29.

Remove Sawdust

From Guide Bar Groove

Sprocket Hole

CRBFTSMHW »

Figure 28

Replace the gukle bar when:

• the inside groove of the guide bar rails is worn.

• the guide bar is bent or cradced.

• excess healing or burring of the rails is noted.

If replacement is necessary, use only the repiacenrent

reduced kiddDack guide bar specified for your saw In the

repair parts list or as specified on ttie replacement bar and

chain decal locatda on fhe chain saw.

[ui m lui nil

i-^File

Correct

Groove

Worn Grooves

File Edges

Square

Figure 29

19

-