Craftsman 137.248830 User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

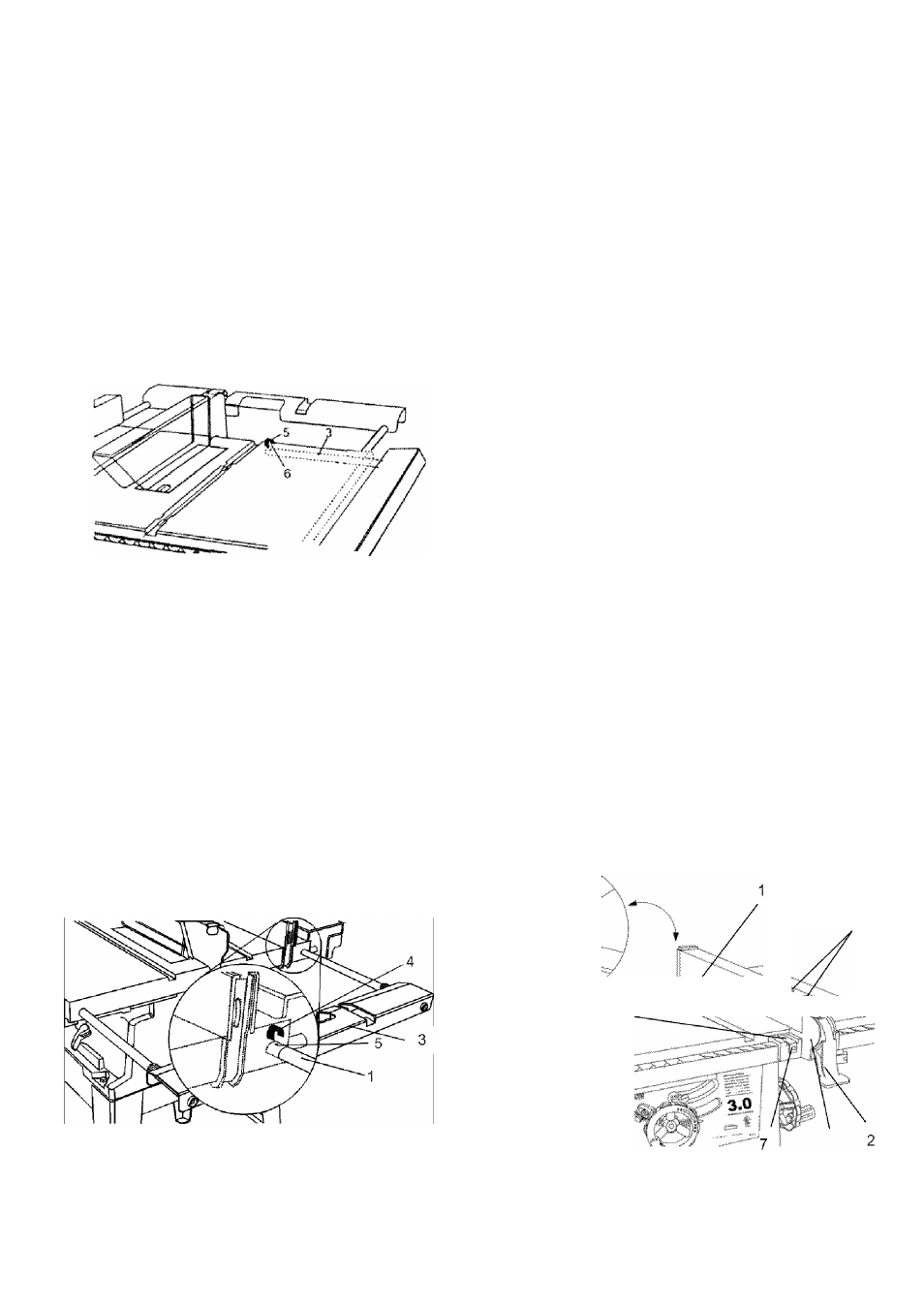

INSTALLING THE TABLE SIDE EXTENSIONS- cont’d

(FIG. O)

6. Snap one location seat (5) over the end of the rear

table extension tube (3). Make sure the locating pin

(6) in the location seat fits into the nnatching hole in

the extension tube (Fig. O).

7. Install the left hand table extension in a similar way.

NOTE;

For illustration purposes the view in Fig. O looks

“through” the saw table to the under side of the table.

Fig.O

INSTALLING REAR TABLE EXTENSION (FIG. P)

1. Place the rear table extension onto the two rear table

extension tubes (1).

2. Snap two location seats (4) over the two rear table

extension tubes (1).Make sure the locating pin in the

location seat fits into the matching hole (5) in the

extension tube.

3. Insert rear table extension tubes (1) into the two

holes in the rear of the saw table and into extension

tube brackets under the table.

Position rear table support so instruction labels

are up.

4. Snap one location seat (4) over the end of the left

rear table extension tube (1). Make sure the

locating pin in the location seat fits into the

matching hole in the extension tube.

Fig. P

ADJUSTING REAR TABLE EXTENSION

1. Rear table extension should be positioned as close

as possible to the rear of the table when ripping

short work pieces.

2. Rear table extension should be pulled out fully until

the location seat prevents it from moving outward

when ripping long work pieces that require extra

support as you are completing the cut.

RIP FENCE ADJUSTMENT (FIG. Q)

1. The fence (1) is moved by lifting up on the handle (2)

and sliding the fence to the desired location. Pushing

down on the handle locks the fence in position.

2. Position the fence on the right side of the table, and

along the miter gauge groove.

3. Lock the fence handle. The fence should be parallel

with the miter gauge groove.

4. If adjustment is needed to make the fence parallel to

the groove, do the following:

• Loosen the two screws (3) and lift up on the handle

(

2

).

• Hold the fence bracket (4) firmly against the front of

the saw table. Move the far end of the fence until it

is parallel with the miter gauge groove.

• Tighten both screws and push the handle to lock.

5. If fence is loose when the handle is in the locked

(downward) position, do the following:

• Move the handle (2) upward and turn the adjusting

nut (5) clockwise until the rear clamp is snug. Do not

turn the adjusting screw more than 1/4 turn at a

time.

• Over-tightening the adjusting screw will cause the

fence to come out of alignment.

A WARNING

Failure to properly align fence can cause “kickback" and

serious injury.

Fig. Q