Craftsman 315.214770 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

I

J

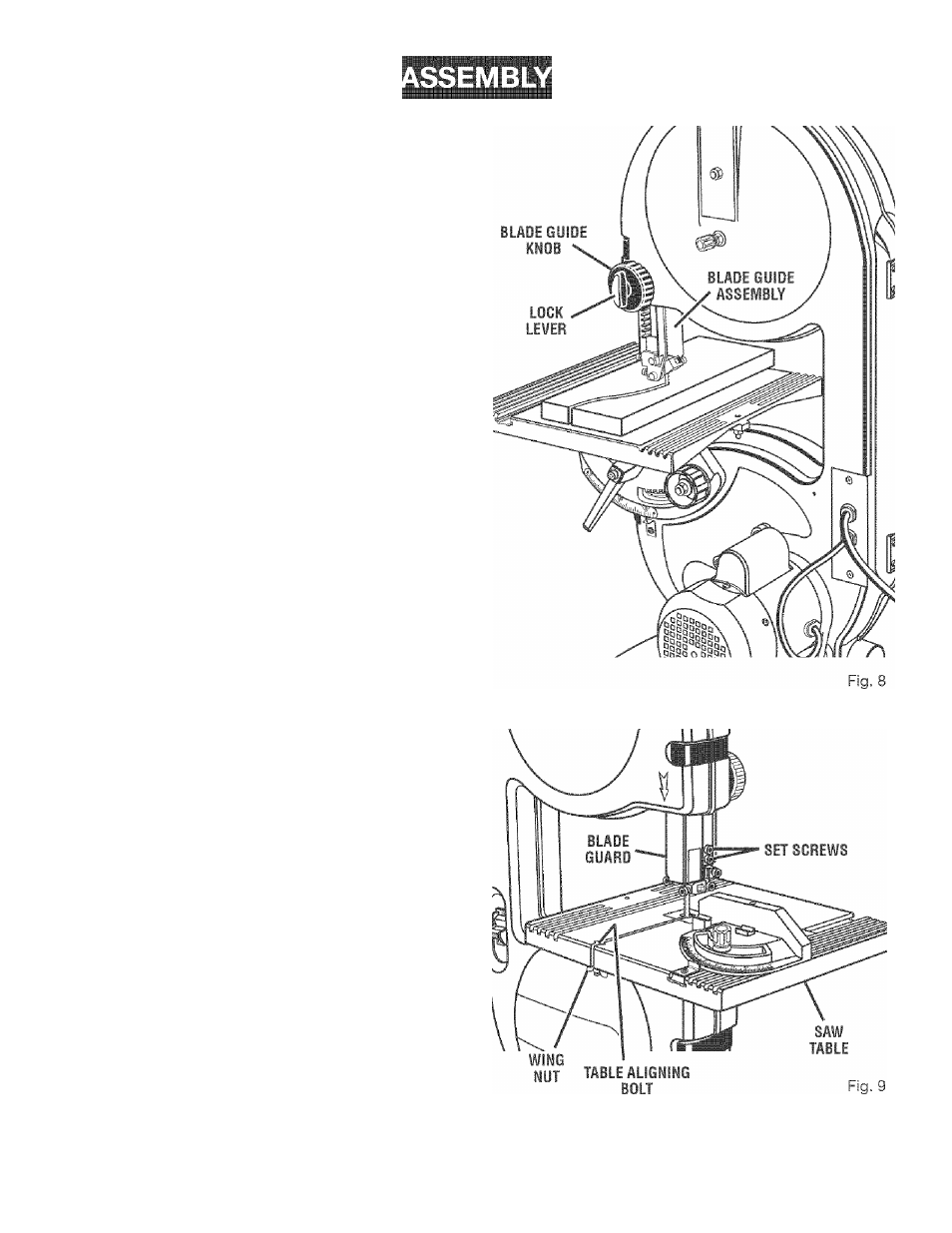

ADJUSTING BLADE GUIDE ASSEMBLY

See Figure 8.

A WARNING; To avoid persona! injury, maintain proper

adjustment of blade tension, blade guides, and thrust

bearings.

To prevent the

blade

from twisting or breaking, the blade

guide assembly should always be set approximately 1/8

in.

above the workpiece.

■ Turn the lock lever counterclockwise to

unlock

the

blade

guide

assembly.

■ As a guide,

use a scrap piece of the same wood you

are about to cut to set the height of the blade guide

assembly. Adjust biade guide assembly by turning the

blade guide knob.

■ Lock blade guide assembly in place by turning the lock

lever

clockwise.

■ Always lock the biade guide assembly in place before

turning on the band saw.

INSTALLING AND ADJUSTING THE BLADE

See Figures 9 - 1 0 .

WARNING: Always

wear safety goggles or safety

glasses with side shields to protect your eyes while

uncoiling band saw blades. Failure to heed this

warning could result in a serious eye

injury.

■ Loosen and remove the wing nut and table aligning

bolt from the saw

table.

■ Remove the saw table before opening the front cover

of the saw housing.

■ Loosen the two set screws that hold the blade guard in

place using

the

4

mm

hex key provided, then remove

the

blade guard.

■ Turn the lock lever counterclockwise to unlock the

biade guide assembly. Turning the blade guide knob

(clockwise raises the blade guide assembly; counter

clockwise lowers it), position the blade guide assembly

about halfway between the saw

table

and saw housing.

Retighten the

lock

lever.

■ Release blade tension by loosening the 8 mm hex nut

then

turning

the

blade

tension knob counterclockwise,

■ Carefully remove the old blade.

NOTE: The spring on the upper wheel allows the wheel

to be pulled down for easier removal of the blade.

■ Wearing gloves, carefully uncoil the blade at arm’s

length. If the new blade was oiled to prevent rust

ing, it may need to be wiped to keep the oil from your

workpiece. Carefully wipe

in

the same direction the

teeth are pointing so the rag does not catch on the

teeth of the saw blade.

14