Add fuel, Connect hose and water supply to pump, Caution – Craftsman 580.752000 User Manual

Page 7: Checklist before starting engine, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

6.

Pour slowly. Wipe dipstick dean each time oii

ievel is checked. DO NOT overfili.

7.

Install oil fill plug and dipstick, tighten securely.

NOTE: Check oil often during engine break-in.

Add Fuel

A

A

WARNING!

NEVER fill fuel tank Indoors.

NEVER fill fuel tank when engine is running or

hot. DO NOT smoke when filling fuel tank.

2

.

3.

WARNING!

NEVER fill fuel tank completely

full. Provide space for fuel expansion. Wipe

away any fuel spillage from engine and

equipment before starting.

Use clean unleaded automotive fuel and store in

approved, clean, covered containers. Use clean fill

funnels. NEVER use “stale" fuel left over from last

season or fuel stored fbr long periods.

Clean area around fuel fill cap, remove cap.

Slowly add fuel to fuel tank. Use a funnel to

prevent spillage. Fill tank to about 1.5” below the

lop of the filler neck.

f

Tank „

£

Fuel

4.

Install fuel cap and wipe up any spilled fuel.

IMPORTANT; It Is Important to prevent gum deposits

from forming in essential fuel system parts, such as the

carburetor, fuel filter, fuel hose or tank during storage.

Also, experience indicates that alcohol-blended fuels

(called gasohol, ethanol or methanol) can attract

moisture, which leads to separation and fomialion of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage of 30 days or longer. See

“Storage" on page 15. NEVER use engine or

carburetor cleaner products in the fuel tank or

permanent damage may occur.

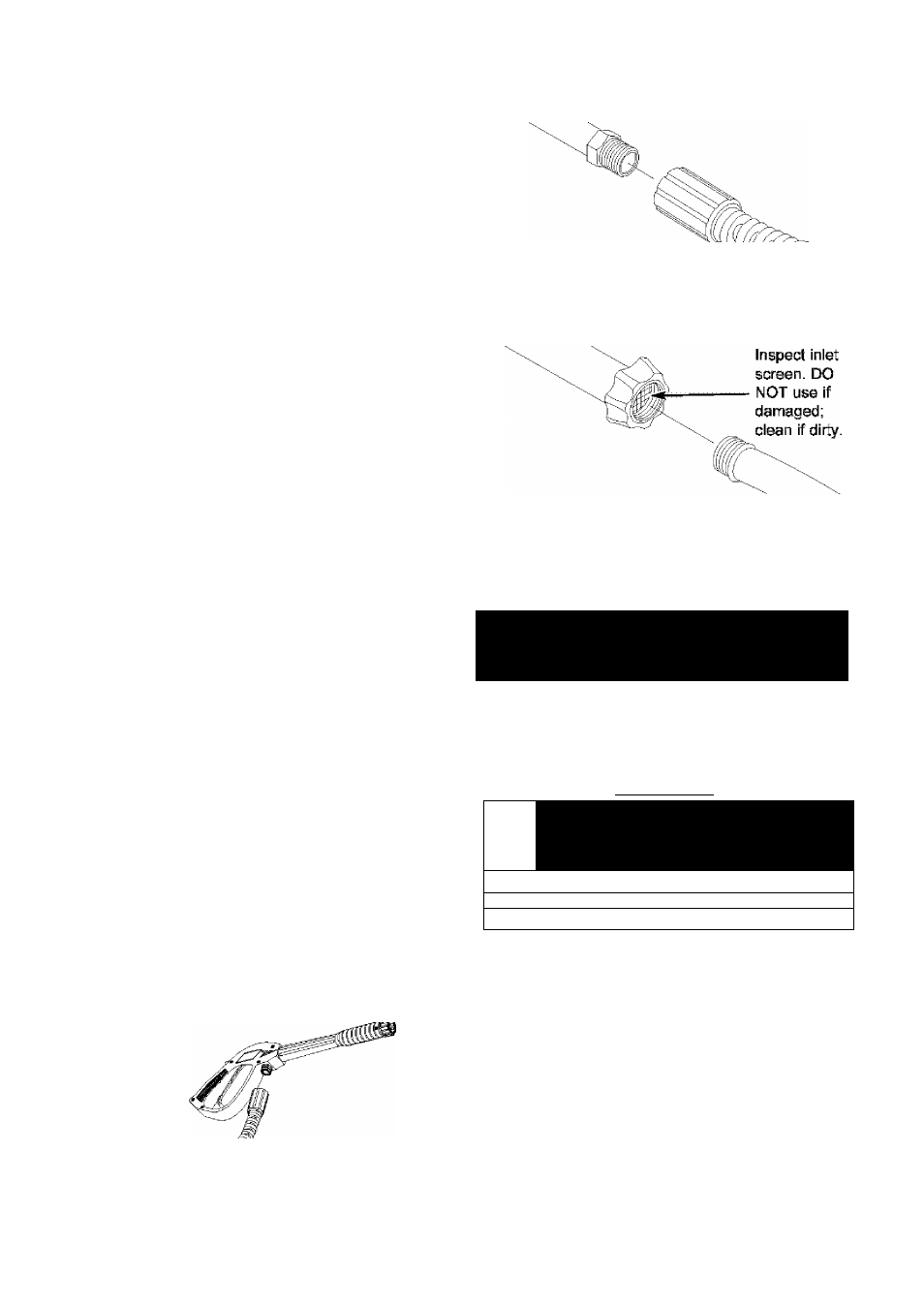

Connect Hose and Water Supply to Pump

IMPORTANT: To avoid pump damage, you must

assemble the nozzle extension to the spray gun and

attach all hoses before you start the engine.

1.

Uncoil high pressure hose and attach one end of

hose to base of spray gun. Tighten by hand.

2.

Attach other end of high pressure hose to high

pressure outlet on pump. Tighten by hand.

3.

Before connecting garden hose to water inlet,

inspect inlet screen. Clean screen if it contains

debris or have it replaced if damaged. Refer to

section “0-Ring Maintenance" if inlet screen is

damaged. DO NOT run pressure washer if inlet

screen is damaged. NEVER siphon inlet water.

5.

Run water through garden hose for 30 seconds to

flush out any debris.

Connect garden hose (not to exceed 50 feet in

length) to water inlet. Tighten by hand.

CAUTION

There MUST be at least ten feet of unrestricted garden

hose between the pressure washer inlet and any flow

shut off device, such as a Y' shut-off connector or

other convenience-type water shut-off valve.

Damaged to equipment resulting IfromTailure tC followl

thisi instructions will voict warranty; 11111111111111

Turn ON water and squeeze trigger on gun to

purge pump system of air and impurities.

WARNING

High pressure spray can cause paint chips

or other particles to become airborne.

Always wear eve protection when usinq this equipment

or

111

vicinity of where equipment isi in use..............................

Before starfinq ttie pressure washer, be sure you are.............

CHECKLIST BEFORE STARTING

ENGINE

Review the unit to ensure you have performed all of

the following:

1.

Check that oil has been added to proper level in

engine crankcase.

2.

Add proper fuel to fuel tank.

3.

Check for properly tightened hose connections

(high pressure and water supply) and there are no

kinks, cuts, or damage to high pressure hose.